Adjustable platform used for assembling and welding of cone stock bins

A silo group and platform technology, which is applied to the scaffolding of building structure support, building structure support, building structure support, etc., can solve the problems of wasting time and energy, affecting the safety of equipment use, and inconvenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings.

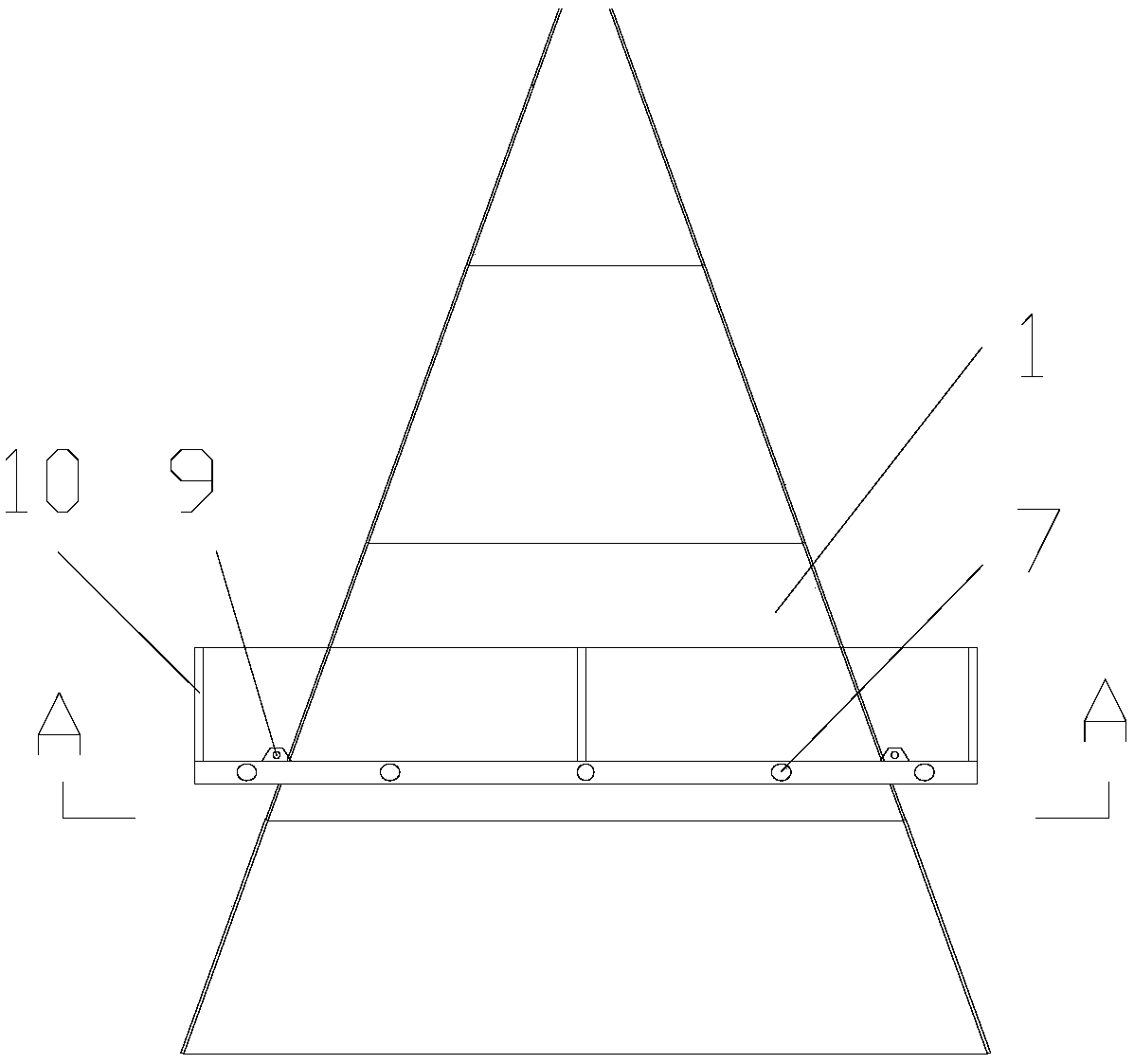

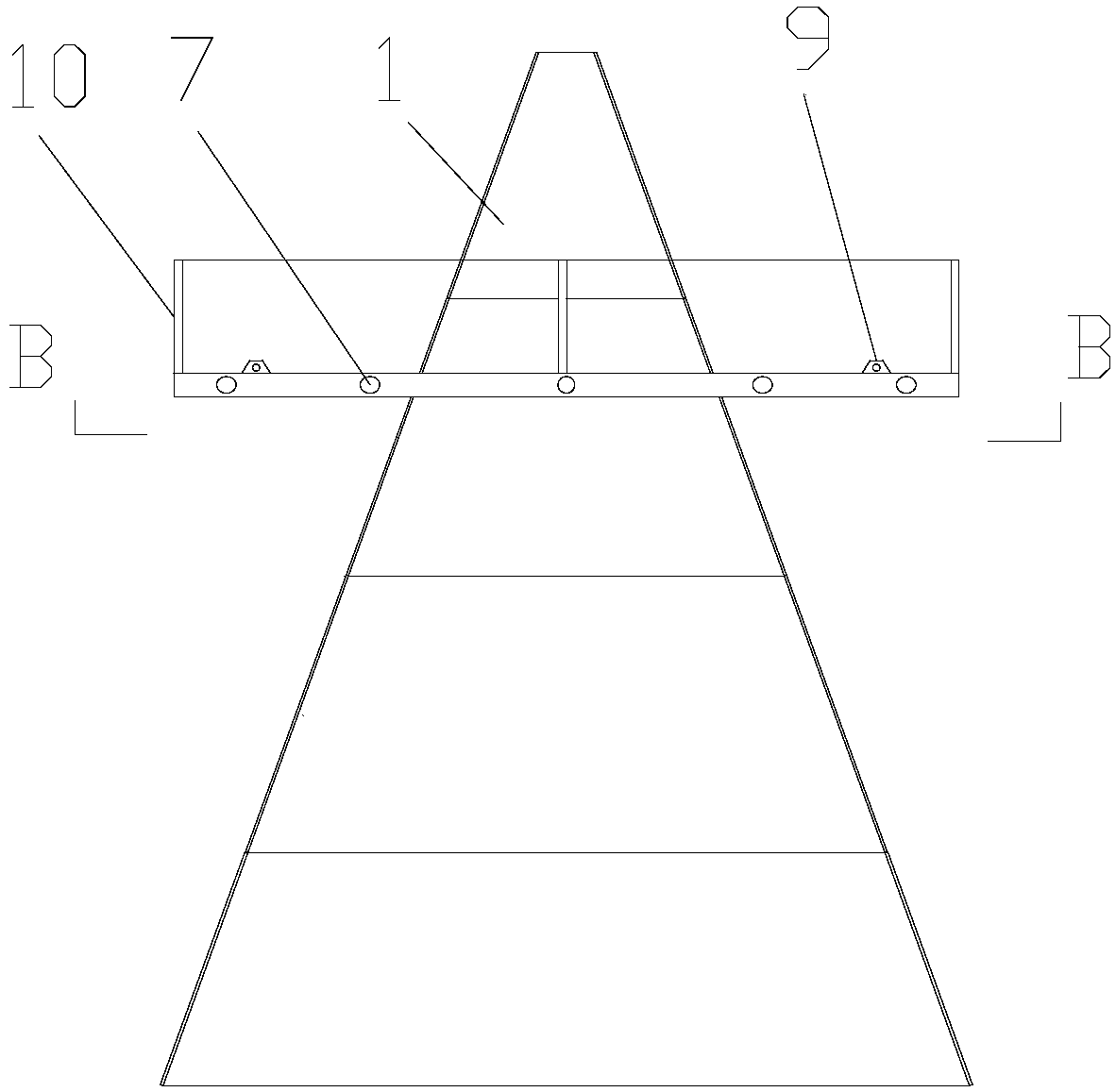

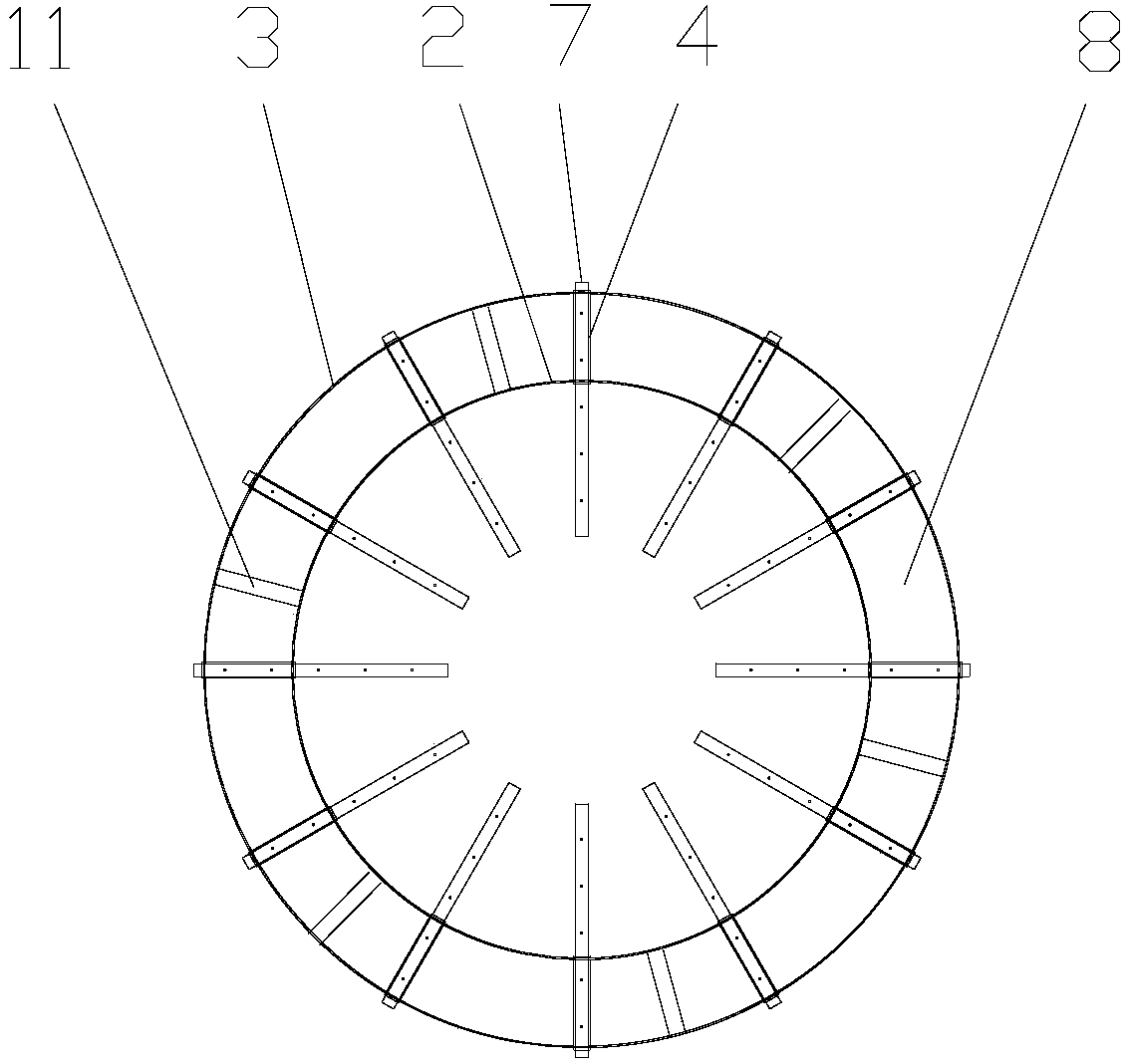

[0014] Such as Figure 1 to Figure 6 shown. The adjustable platform for assembly and welding of cone silos includes an inner ring plate 2 and an outer ring plate 3 placed on the same plane, the inner ring plate 2 and the outer ring plate 3 are connected by a plurality of sleeves 4, so The inner through-hole 5 and the outer through-hole 6 are respectively opened at the connection positions of the inner ring plate 2 and the outer ring plate 3 with the sleeve 4, and the limit rod 7 is set inside the sleeve 4, and the limit rod 7 and the The casing 4 is movably connected, and the stop rod 7 is fixed with the casing 4 after passing through the inner through hole 5, the casing 4 and the outer through hole 6. The shape of the inner ring plate 2 and the outer ring plate 3 of the adjustable platform Determined according to the external shape of the cone silo 1 to be assembled...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com