Device for removing heat and its manufacturing method

A technology of equipment and heat-conducting elements, which is applied in the field of heat-extracting equipment and its manufacturing, can solve space problems and other problems, and achieve the effect of improving heat conduction capacity or heat distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

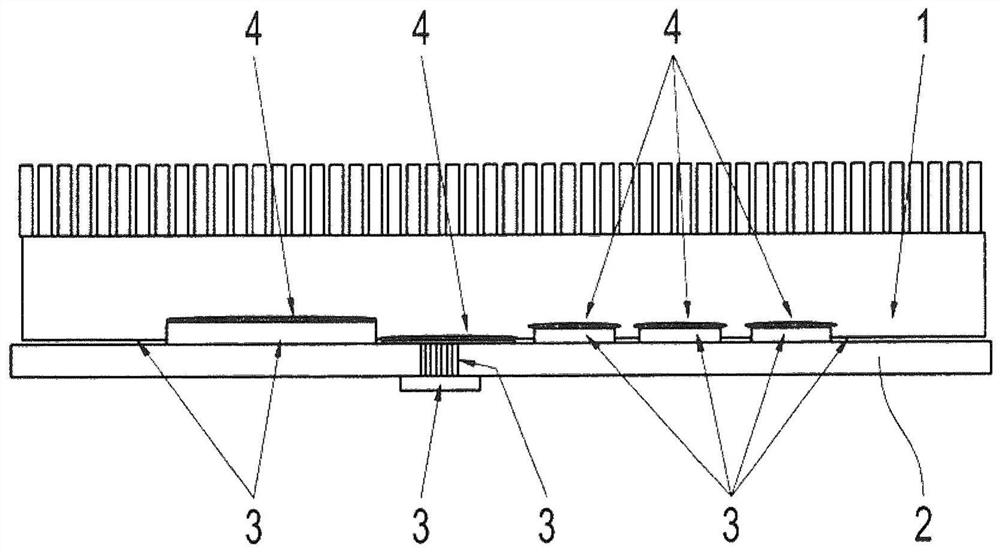

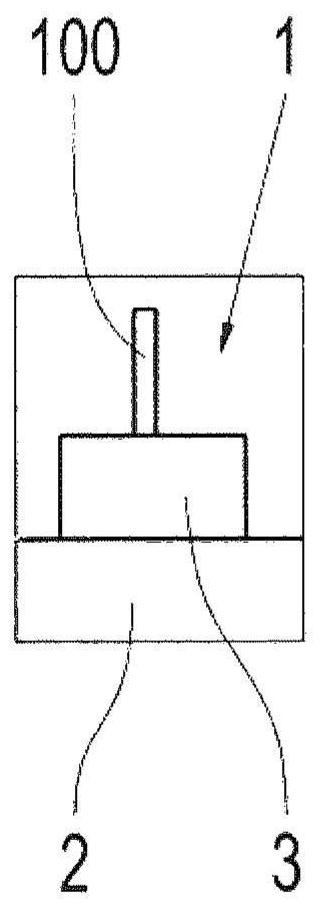

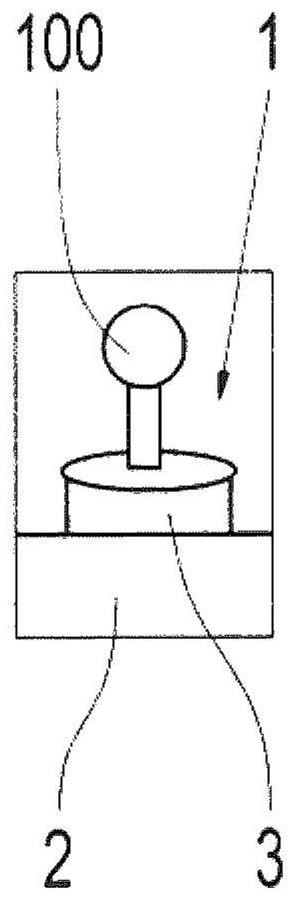

[0023] For better thermal connection or heat dissipation between the heat sink and the components arranged on the printed circuit board, the method according to the invention makes it possible to dispense with intermediate layers. For better heat-conducting connection of the cooling body, the heat-conducting element can be integrated directly into the cooling body, or it can be integrated as a separate component during manufacture. The heat-conducting element has a special structure and is preferably at least partially filled with a heat-conducting medium, hereinafter only referred to as medium. The medium can here be present with or without circulation in the closed heat-conducting element or be in contact with the respective component, ie the heat-conducting element has a direction along the component(s) on which it is arranged Open structure. Thermally conductive elements can also be purchased or manufactured as separate components to be mounted on one or more components a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com