Improved assembling-fastening part for flue gas desulfurization equipment

A technology for desulfurization equipment and fastening parts, which is applied in the field of assembly and fastening parts for improved flue gas desulfurization equipment, can solve the problems that the installation of fastening parts cannot meet the needs of installation, and achieve reliable connection stability, good tightness, The effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

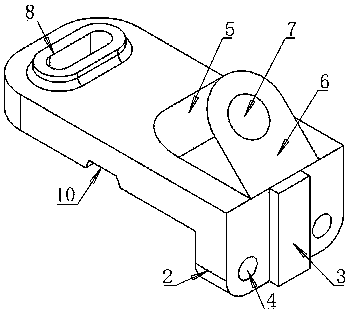

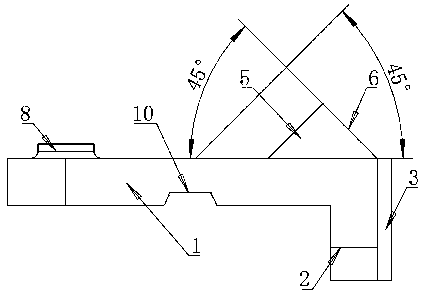

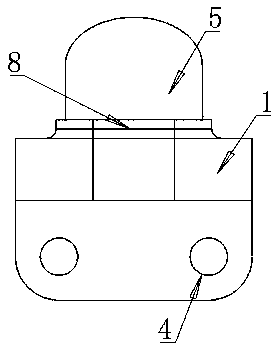

[0019] Such as Figure 1 to Figure 7 As shown, an improved assembly and fastening part for flue gas desulfurization equipment is produced with a new structural design, which can meet the installation requirements of flue gas desulfurization at a specific angle during use, and is tightened by this assembly during installation. The assembly, positioning, connection and stabilization plate provided on the fixed part can make the tightness of the assembly and connection better, and through this assembly fastener, it can be assembled with multiple positions of the flue gas desulfurization equipment at the same time, which makes the operation during assembly more convenient and can Instead of the traditional multiple parts cooperating with each other to make the assembly more efficient, this assembly fastening part sets a trapezoidal assembly anti-loosening connection assembly groove at the lower end of the main body assembly position, so that further assembly can be carried out thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com