Excitation control method of wide plate roller type straightening machine

A roll-type straightening machine and excitation control technology, applied in the field of aluminum alloy sheet straightening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

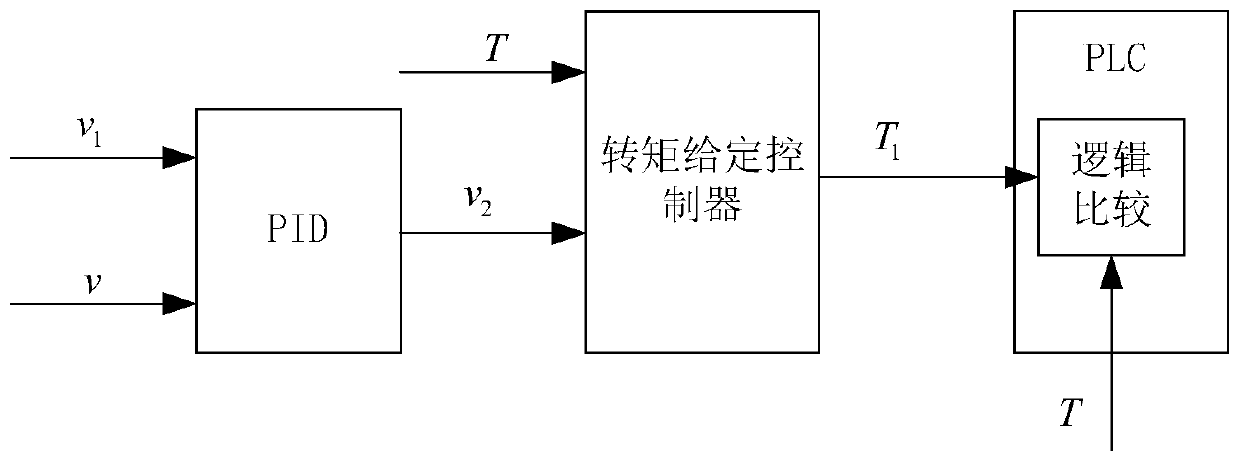

[0021] Specific implementation mode one: refer to figure 1 Describe this embodiment specifically, the excitation control method of a kind of wide plate roller straightening machine described in this embodiment,

[0022] First, collect the actual rotational speed v of the driving motor of the bottom straightening roller in the straightening machine, and compare the actual rotational speed v with the given speed v 1 One pass is input to PID (Proportion Integration Differentiation) to obtain the speed value that needs to be adjusted, that is, to adjust the speed v 2 ,details as follows:

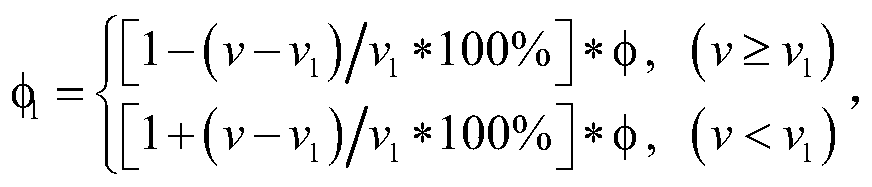

[0023] According to the actual speed v and the given speed v 1 Obtain the adjusted magnetic flux φ 1 ,

[0024]

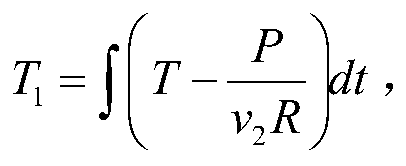

[0025] Adjust the magnetic flux φ according to 1 Get adjusted speed v 2 :

[0026] v 2 = φ 1 / S·L·E;

[0027] In the above formula, φ represents the rated magnetic flux of the motor, S represents the cross-sectional area of the wire, L represents the length of the wire...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com