Motor and control device therefor

A control device, stator pole technology, applied in the direction of motor control, AC motor control, electromechanical devices, etc., can solve the problems of power factor torque ripple increase, noise, inverter size increase, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

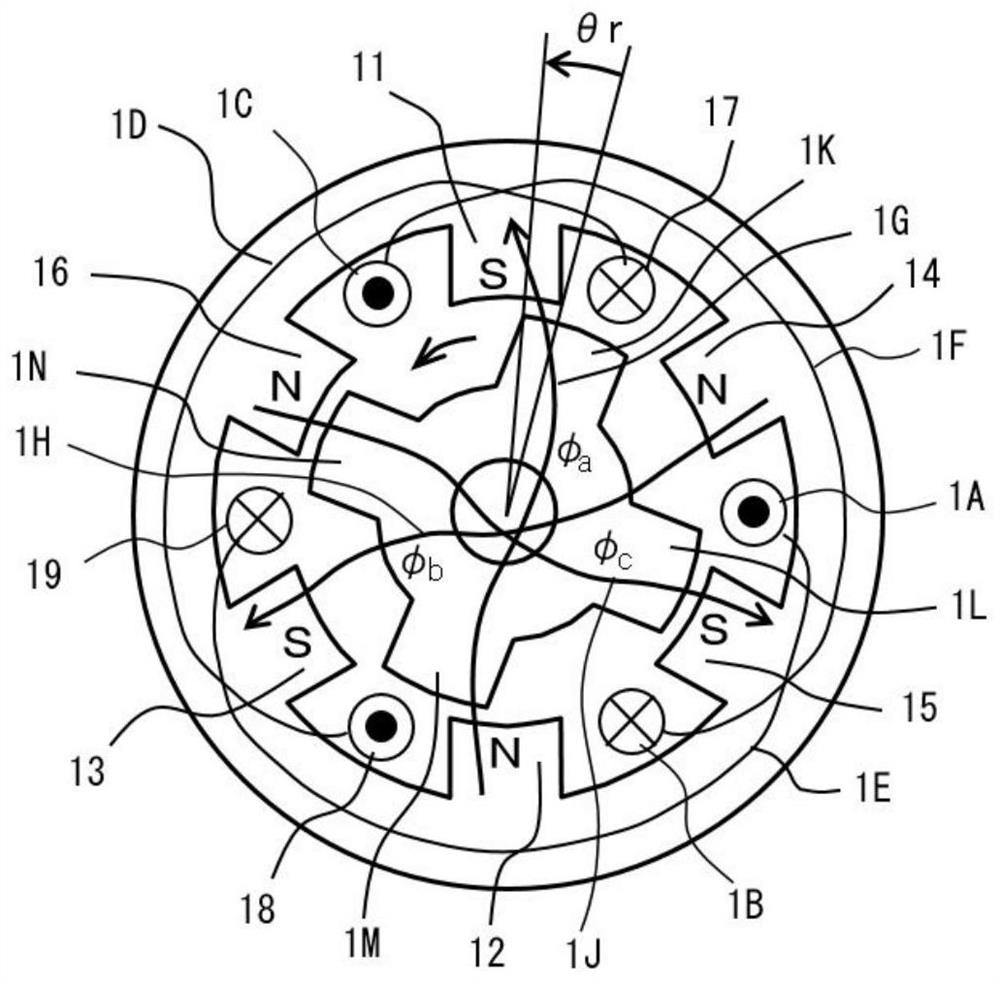

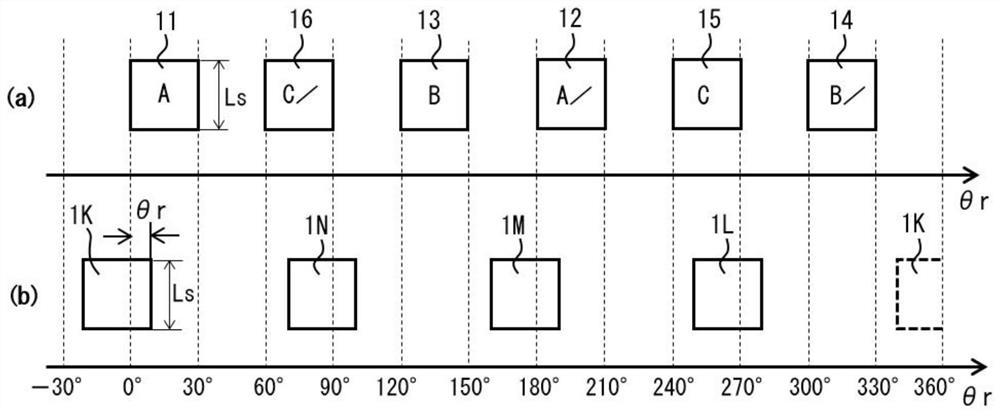

[0153] figure 1 An example of a transverse cross-sectional view of the magnetoresistance motor of the present invention is shown. figure 1 The circumferential direction of the stator magnetic poles 11, 12, 13, 14, 15, 16 is 30 °, and the equal intervals are disposed in six places of the whole circle. The rotor magnetic poles 1K, 1L, 1M, and 1N have a circumferential direction of 30 °, equal intervals are disposed in four places of the entire circumference. figure 1 The shape of the stator magnetic pole and the rotor magnetic pole and the above Figure 83 The magnetic pole shape is the same. figure 1 The purpose of the composition is to increase the cross-sectional area of each winding in the groove to 2 times, and the copper damage in the groove is lowered.

[0154] for figure 1 Each winding is shown Figure 83 The concentrated windings of the respective stator magnetic poles shown are converted to a full length scaner winding, and two concentration windings in each slot are comb...

Embodiment 2

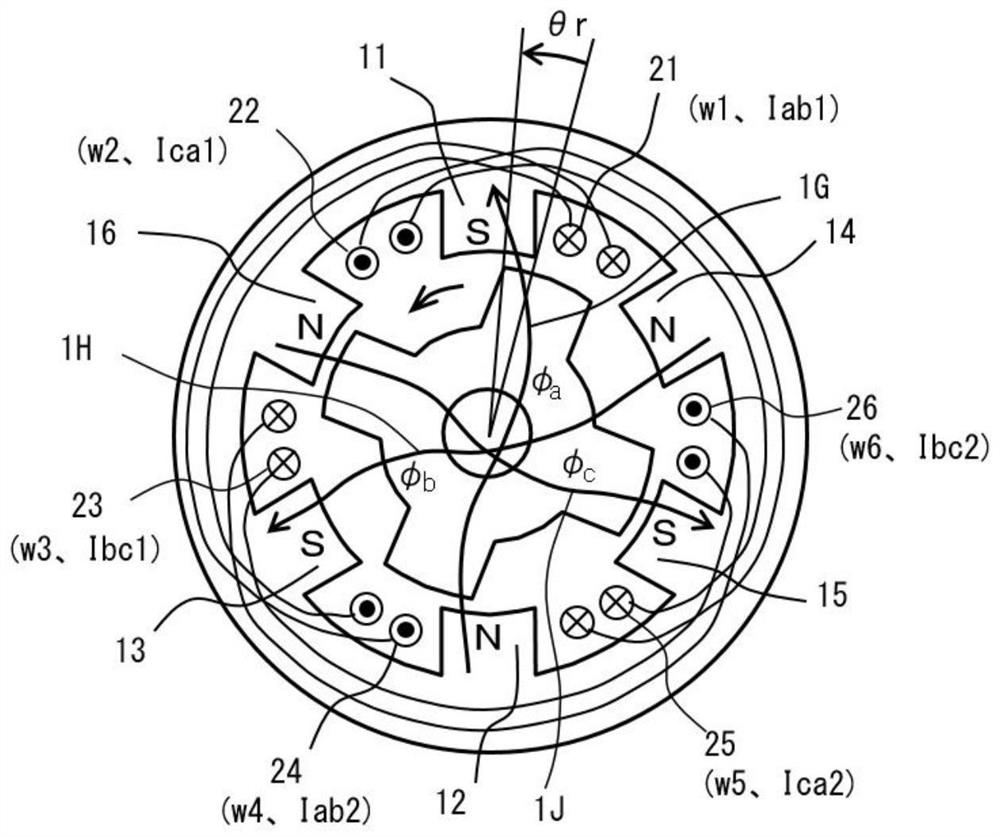

[0329] Next, other embodiments of the first aspect of the driving circuit Figure 7 Shown and described. exist figure 1 Motor, the number of full-pitch windings as few as three, is an odd number, in the case of two windings connected in series and each of the energization method, requires an asymmetrical portion, the load generated on the circuit. In order to eliminate the burden on such a circuit, such as figure 2 , There is shown a set of phase windings each connected in parallel constituting the winding, and is set by six windings Image 6 The exemplary drive circuit driving. exist Image 6 In each phase the voltage and current is driven into two groups, thus increasing the number of transistors is six, but no load on the above-described circuit, the current value of 1 / 2 of each of the transistors, the current of all the transistors the total capacity of a small value, when simply considering logically, the inverter can be downsized.

[0330] Figure 7 Direct drive figure 1 The me...

Embodiment 3

[0336] Next, other embodiments of the first aspect of the driving circuit Figure 8 Shown and described. Above Figure 7 , Image 6 , The new increase of transistor 81 and diodes 82,83,84. exist Figure 8 Drive circuit, B-phase current component Ib from the transistor 61 through the AB-phase full-pitch winding 67 through the diode 84, transistor 81 be passed through. Another B-phase full-pitch current component Ib through transistor 63 from the BC phase winding 69 through diode 83, transistor 81 be passed through. By the transistor 81 through the parallel windings 67 and the B-phase current component 69 Ib. In this case, if Figure 14 Voltage illustrated example, by a change in magnetic flux through the other adverse effects caused by large phase voltage, but the voltage of transistor 81 is twice configuration can be applied to the two windings, voltage problems can be eliminated. Smaller voltage interference. However, since the transistor 81 through the parallel component B-phase curr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com