A constant power loss model predictive control method for hidden pole hybrid excitation motor

A hybrid excitation motor and loss model technology, which is applied in motor generator control, electronically commutated motor control, control systems, etc., can solve the problems of large loss in high-speed areas and low output capabilities of motors and inverters in low-speed areas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

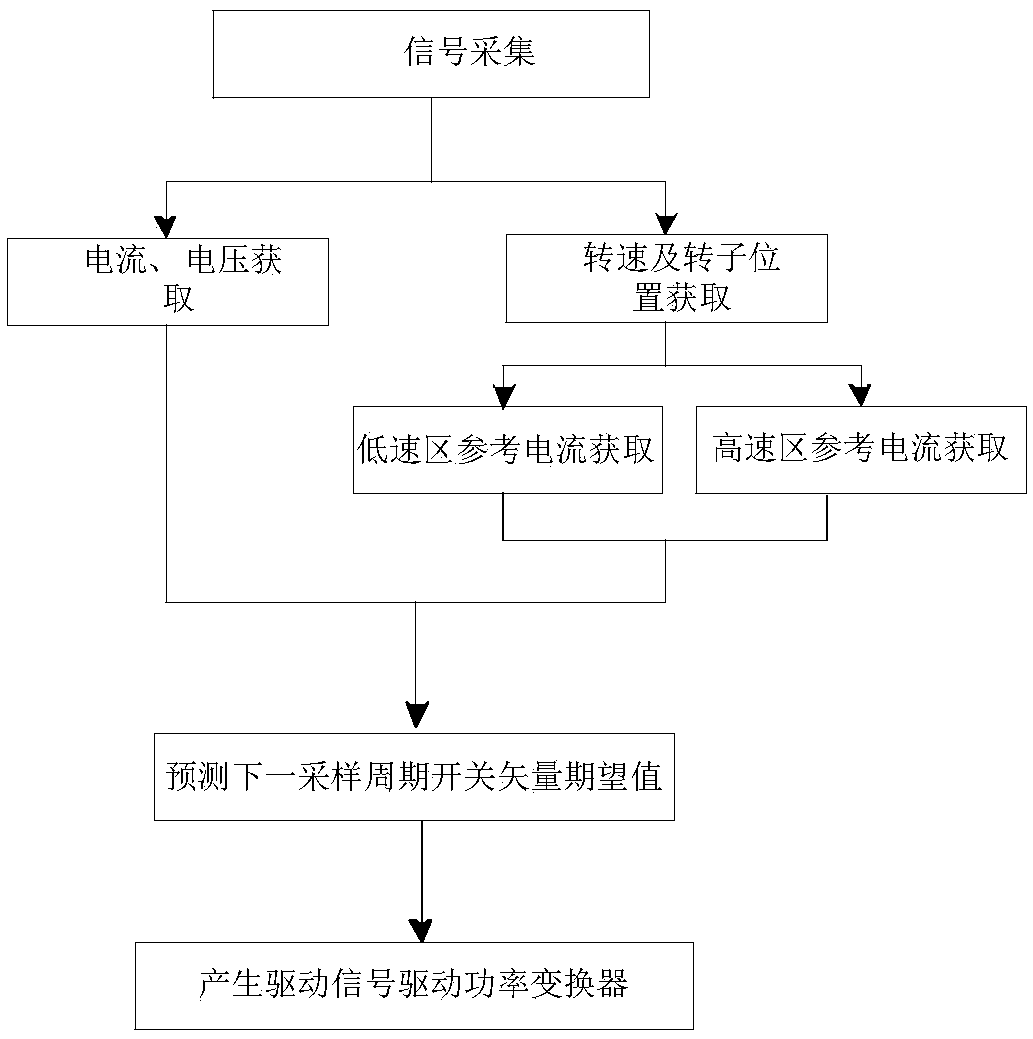

Method used

Image

Examples

Embodiment Construction

[0085] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

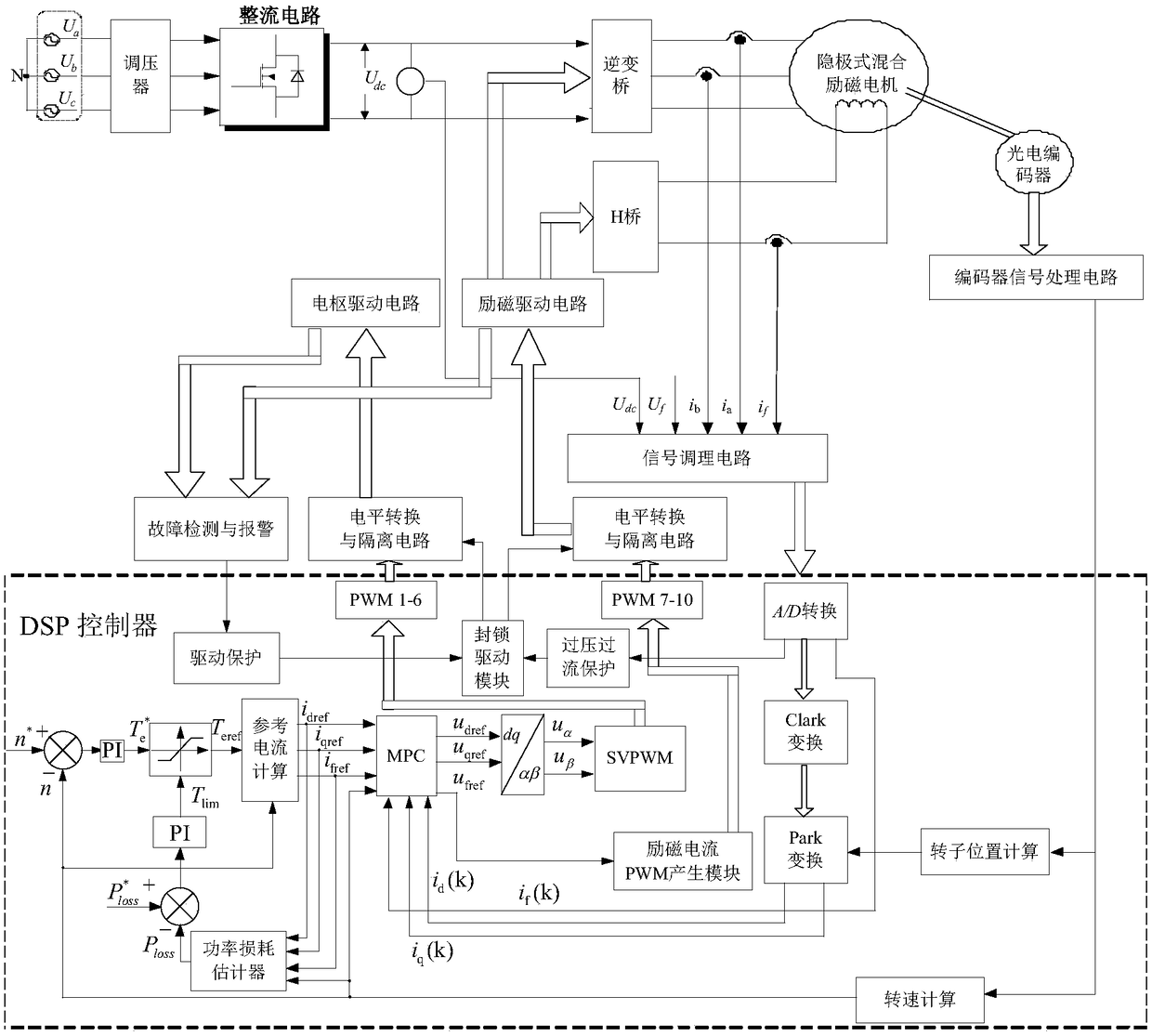

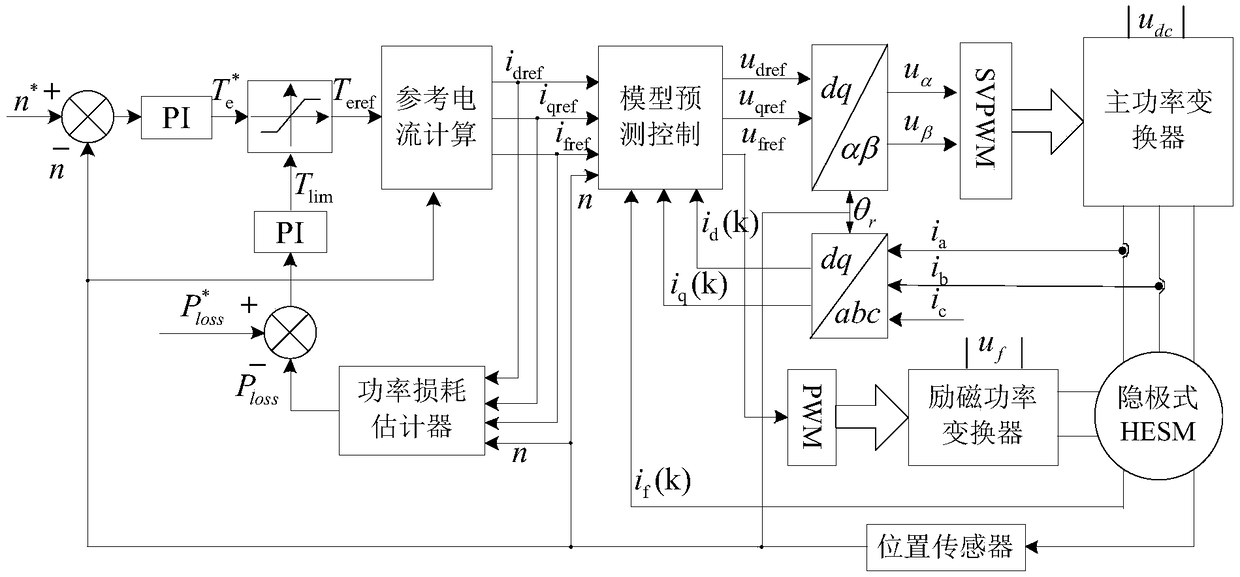

[0086] The system block diagram of the constant power loss model predictive control method of a hidden pole type hybrid excitation motor of the present invention is as follows figure 2 As shown, the control system is composed of AC power supply, rectifier, voltage stabilizing capacitor, main power converter, excitation power converter, current and voltage sensors, hybrid excitation synchronous motor, photoelectric encoder, DSP controller, etc.

[0087] The AC power supply supplies power to the entire system. After being rectified by the rectifier, the voltage is filtered and stabilized, and sent to the main and excitation power converters. The Hall voltage sensor collects the bus voltage and sends it to the controller after conditioning. The output terminals of the main and excitation power converters are connected to the hybrid excitation s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com