Manufacturing method of hand pan

A production method and hand dish technology, applied in the field of musical instruments, can solve problems such as irregular sound range, difficult pitch adjustment, slow speed, etc., and achieve the effects of reducing labor costs, fast production speed, and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

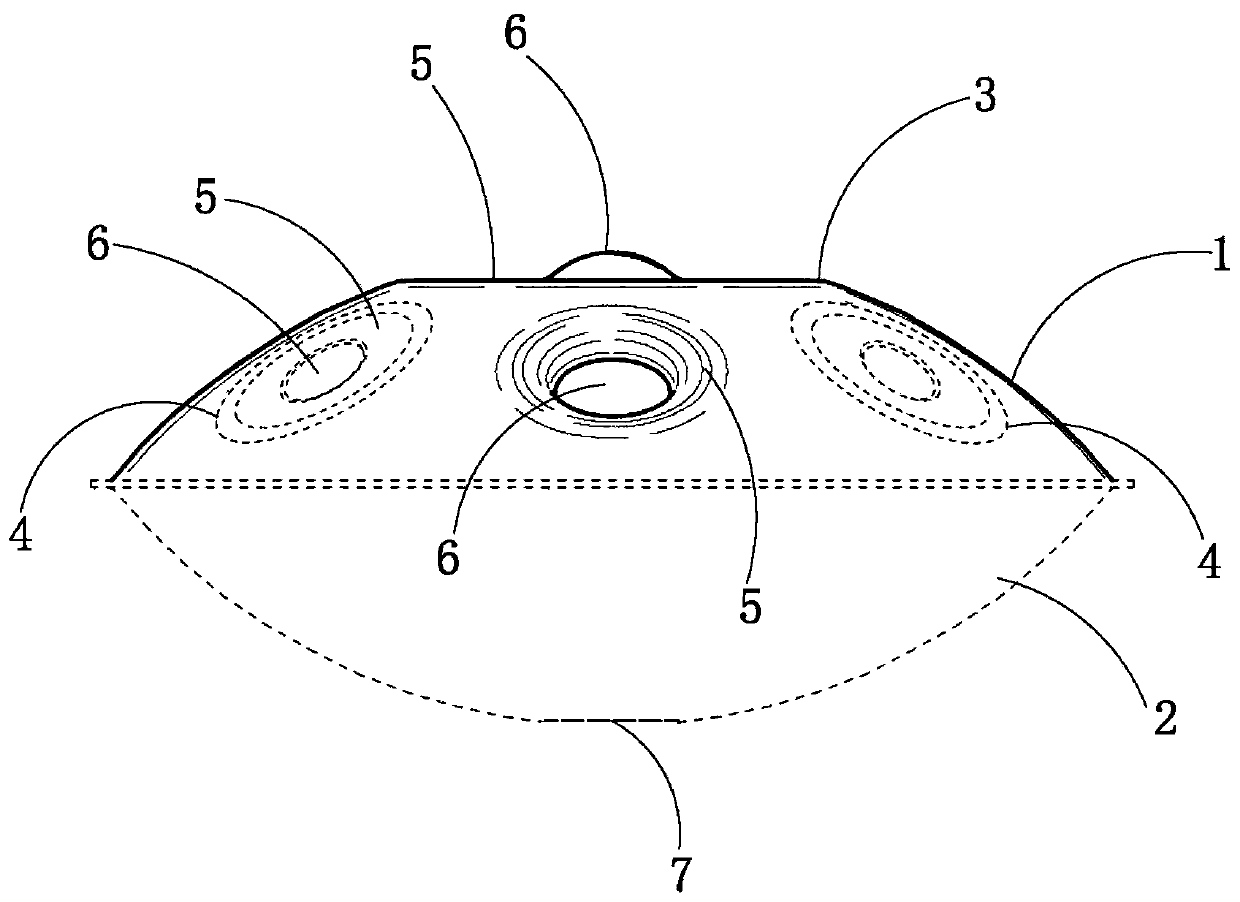

[0027] Further set forth the specific embodiment of the present invention below in conjunction with accompanying drawing and specific embodiment:

[0028] A method for making an astrolabe hand dish, including raw material selection, mold making, shell making, sound zone making, tuning, high temperature oxidation, assembly, and secondary tuning. The specific process is:

[0029] Choose cold-rolled steel or stainless steel as the raw material, and cut the raw material into a square that matches the size of the astrolabe hand dish to be made. The cold-rolled steel is preferably DC04 and DC06 cold-rolled steel, and the stainless steel is preferably stainless steel 430 and 304;

[0030] The mold is a stamping mold, including the overall mold and the sound area mold. The concave and convex of multiple sound areas are different, so that each sound area of the astrolabe hand plate emits different sounds. The overall mold is consistent with the shell of the astrolabe hand plate. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com