Thermal management system used for electric automobile

A thermal management system and electric vehicle technology, applied in the field of electric vehicles, can solve the problems of reducing the mileage of electric vehicles, battery power loss, insufficient heating capacity of heat pumps, etc., to achieve the effect of improving low-temperature heating capacity and saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

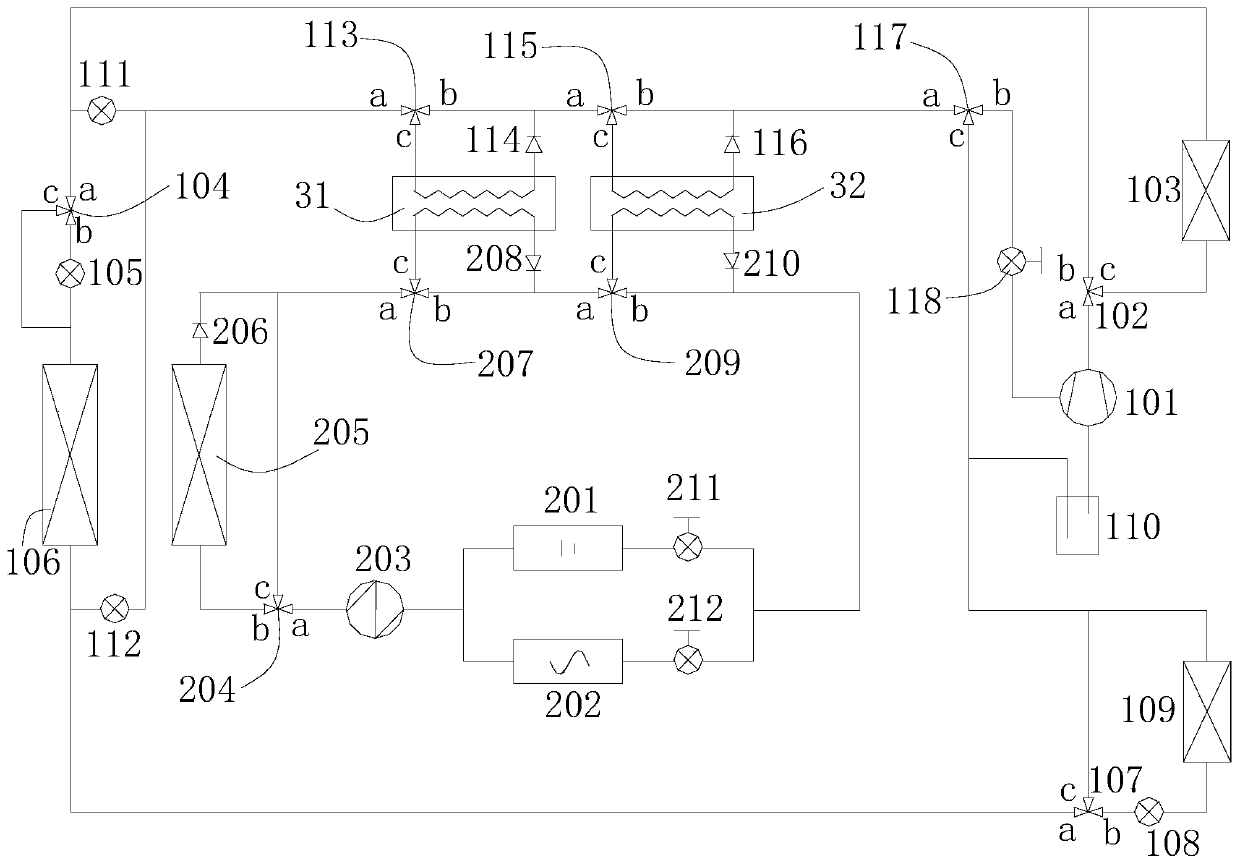

Embodiment 1

[0026] refer to figure 1 , is a thermal management system for electric vehicles, including a compressor 101, a cabin condenser 103, a first throttle valve 105, a first outdoor heat exchanger 106, a second throttle valve 108, a cabin evaporator Device 109, gas-liquid separator 110, third throttle valve 111, fourth throttle valve 112, heat accumulator 31, first check valve 114, first heat exchanger 32, second check valve 116, second A solenoid valve 118, a battery heat exchange module 201, a motor heat exchange module 202, a liquid pump 203, a second external heat exchanger 205, a third one-way valve 206, a fourth one-way valve 208, and a fifth one-way valve 210 , the second solenoid valve 211 and the third solenoid valve 212;

[0027] The compressor 101, the cabin condenser 103, the first throttle valve 105, the first outdoor heat exchanger 106, the second throttle valve 108, the cabin evaporator 109, and the gas-liquid separator 110 are connected in sequence, and the third sect...

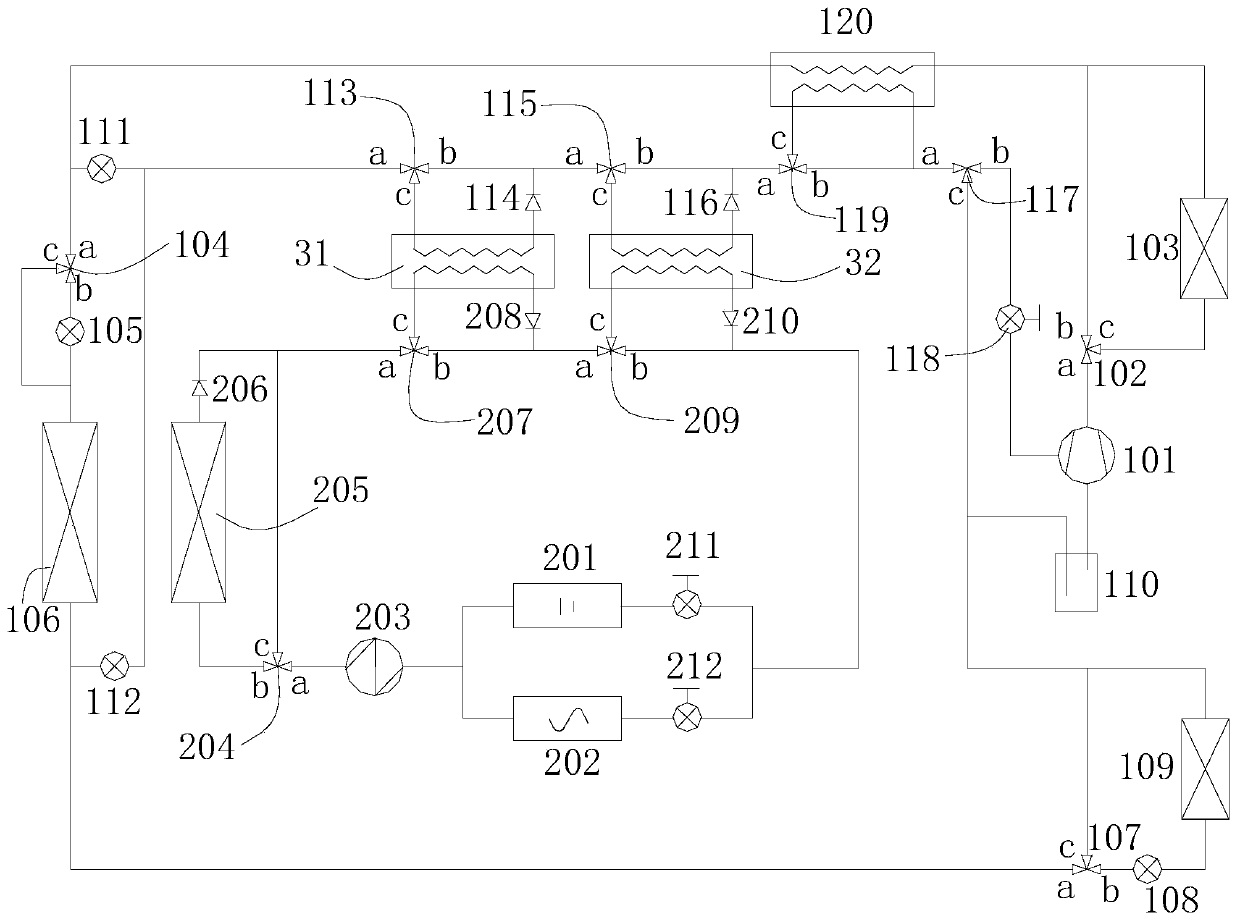

Embodiment 2

[0038] refer to figure 2 , is another thermal management system for electric vehicles. The difference between Embodiment 2 and Embodiment 1 is that: the air-conditioning heat pump system also includes a seventh three-way valve 119 and a second heat exchanger 120; the second heat exchanger The first inlet of the device 120 is connected with the outlet of the cabin condenser 103, the first outlet of the second heat exchanger 120, the first end of the second three-way valve 104 and the inlet of the third throttle valve 111 are connected; the seventh and third The first end of the through valve 119, the second end of the fifth three-way valve 115 and the outlet of the second one-way valve 116 are connected; the third end of the seventh three-way valve 119 is connected with the second inlet of the second heat exchanger 120 The second outlet of the second heat exchanger 120, the second end of the seventh three-way valve 119 and the first end of the sixth three-way valve 117 are con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com