Heat-accumulating-type heat pump system for vehicle

A heat pump system and heat storage technology, applied in heat recovery systems, vehicle components, heating/cooling equipment, etc., can solve problems such as insufficient heating, melting through the air-conditioning box, and reducing the service life of fans, so as to reduce the safety of driving Risk of accidents, improvement of the operating environment, and the effect of reducing the system pressure ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] Embodiment 1, heat pump system

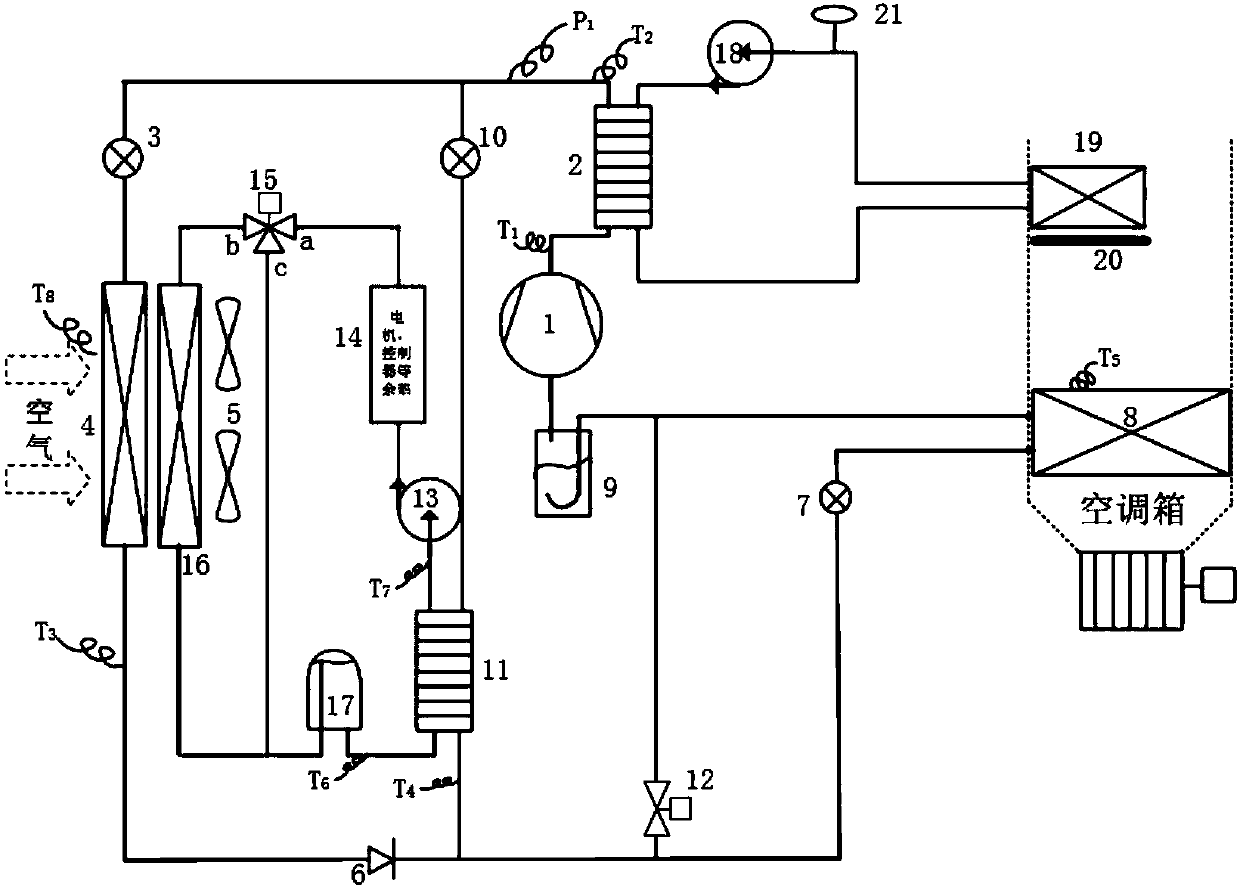

[0065] Such as figure 1 As shown, the vehicle heat storage heat pump system of the present invention preferably includes three subsystems: a refrigerant circulation system, a secondary loop system, and a heat storage circulation system, wherein:

[0066] The refrigerant circulation system includes: a compressor 1, a first heat exchanger 2, a first electronic expansion valve 3, a second heat exchanger 4, a fan 5, a one-way valve 6, and a second electronic expansion valve 7, located in the air conditioning box Inside the third heat exchanger 8, the liquid storage separator 9, the third electronic expansion valve 10, the fourth heat exchanger 11, and the shut-off valve 12, wherein:

[0067] The compressor 1, the first heat exchanger 2, the first electronic expansion valve 3, the second heat exchanger 4, the one-way valve 6, the second electronic expansion valve 7, and the third heat exchanger 8 located in the air conditioning box , and th...

Embodiment 2

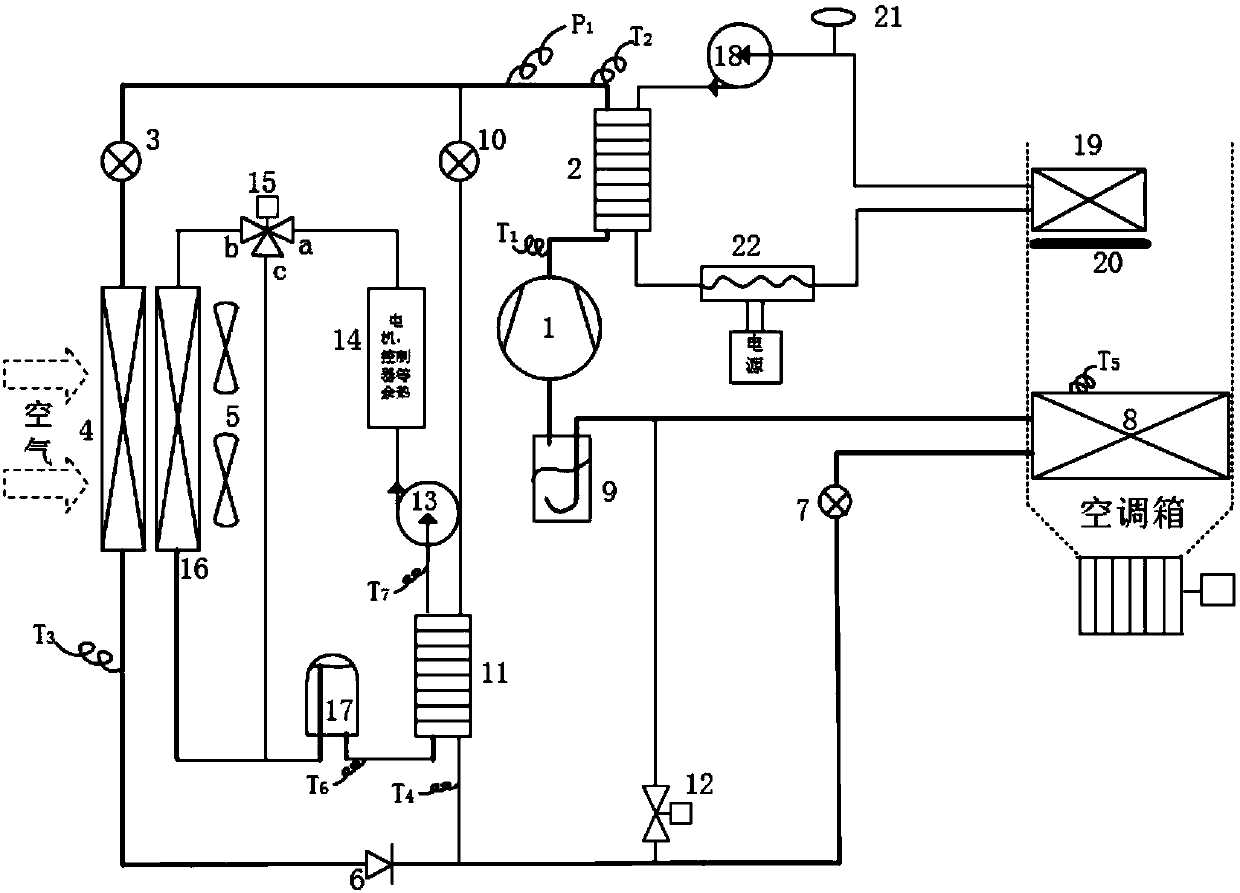

[0093] Embodiment 2, cooling mode

[0094] When the temperature inside and outside the car is high and the temperature inside the car needs to be lowered, the system operates in cooling mode.

[0095] Such as Figure 4 As shown, in the refrigerant circulation system, the high-temperature and high-pressure gaseous refrigerant discharged from the compressor 1 passes through the first heat exchanger 2 and the first electronic expansion valve 3, and the first electronic expansion valve 3 has a certain opening degree for throttling. After throttling It becomes a two-phase refrigerant, enters the second heat exchanger 4, releases heat into the atmosphere of the external environment, and becomes a liquid refrigerant, and then passes through the check valve 6, and all the liquid refrigerant flows into the second electronic expansion valve 7 for throttling , becomes a low-temperature and low-pressure two-phase refrigerant, enters the third heat exchanger 8, absorbs the heat blown by t...

Embodiment 3

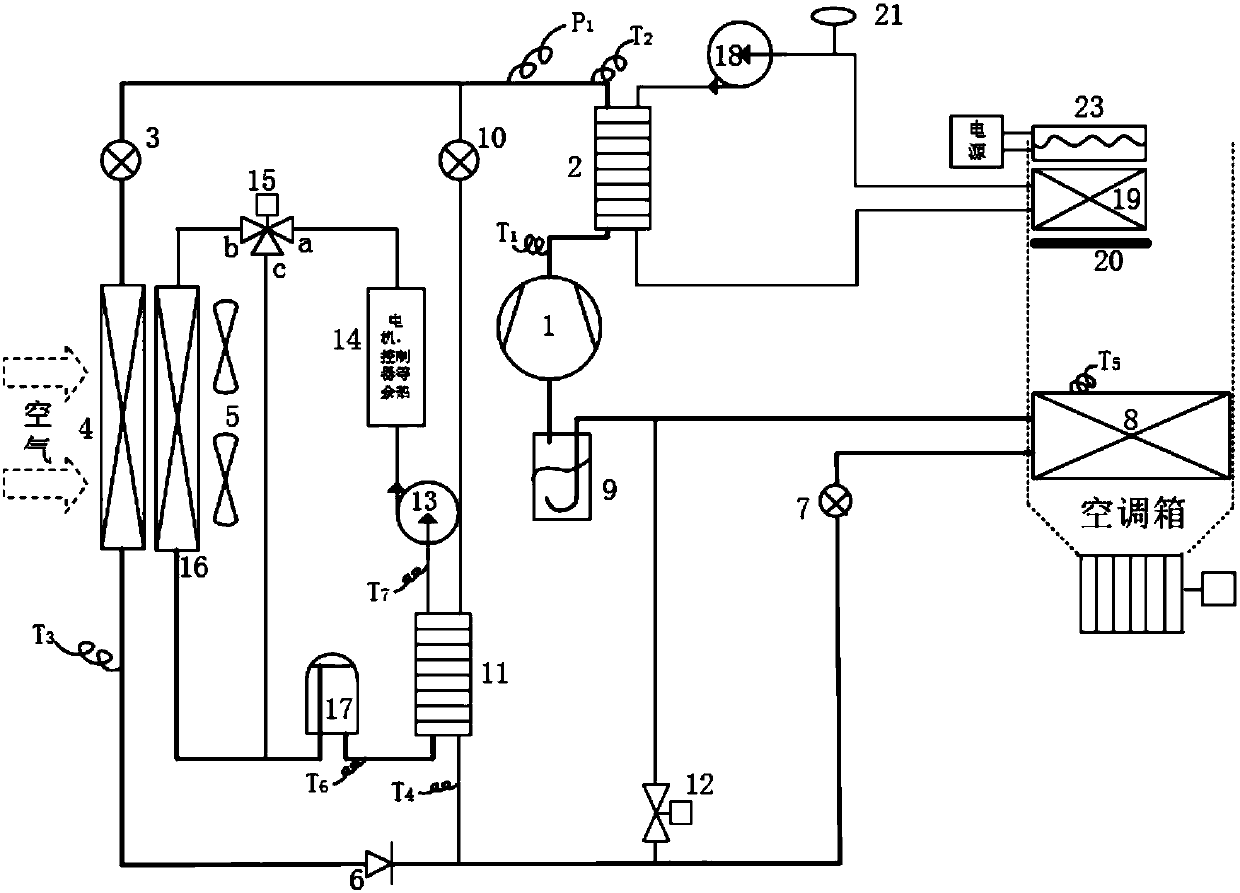

[0098] Embodiment 3, heat pump mode with abundant residual heat

[0099] When the residual heat of the motor, controller, etc. is abundant, and the passenger compartment needs to be heated at the same time, the system operates the first heat pump mode.

[0100] Such as Figure 5 As shown, in the refrigerant circulation system, the high-temperature and high-pressure gaseous refrigerant discharged from the compressor 1 passes through the first heat exchanger 2, releases heat to the circulating liquid in the secondary circuit circulation system, becomes a liquid refrigerant, and passes through the third electronic expansion valve 10 After throttling, it enters the fourth heat exchanger 11, absorbs the heat of the circulating liquid in the fourth heat exchanger 11, becomes a gas-liquid two-phase or gaseous refrigerant, and all flows into the first bypass passage, passes through the stop valve 12, and completely flows into the storage tank. In the liquid separator 9, the separated...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com