Sewage-removing gas-discharging device

An exhaust device and sewage pipe technology, which is applied in the fields of water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc. At the same time, it can achieve the effect of easy operation, improved performance and excellent sewage discharge effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

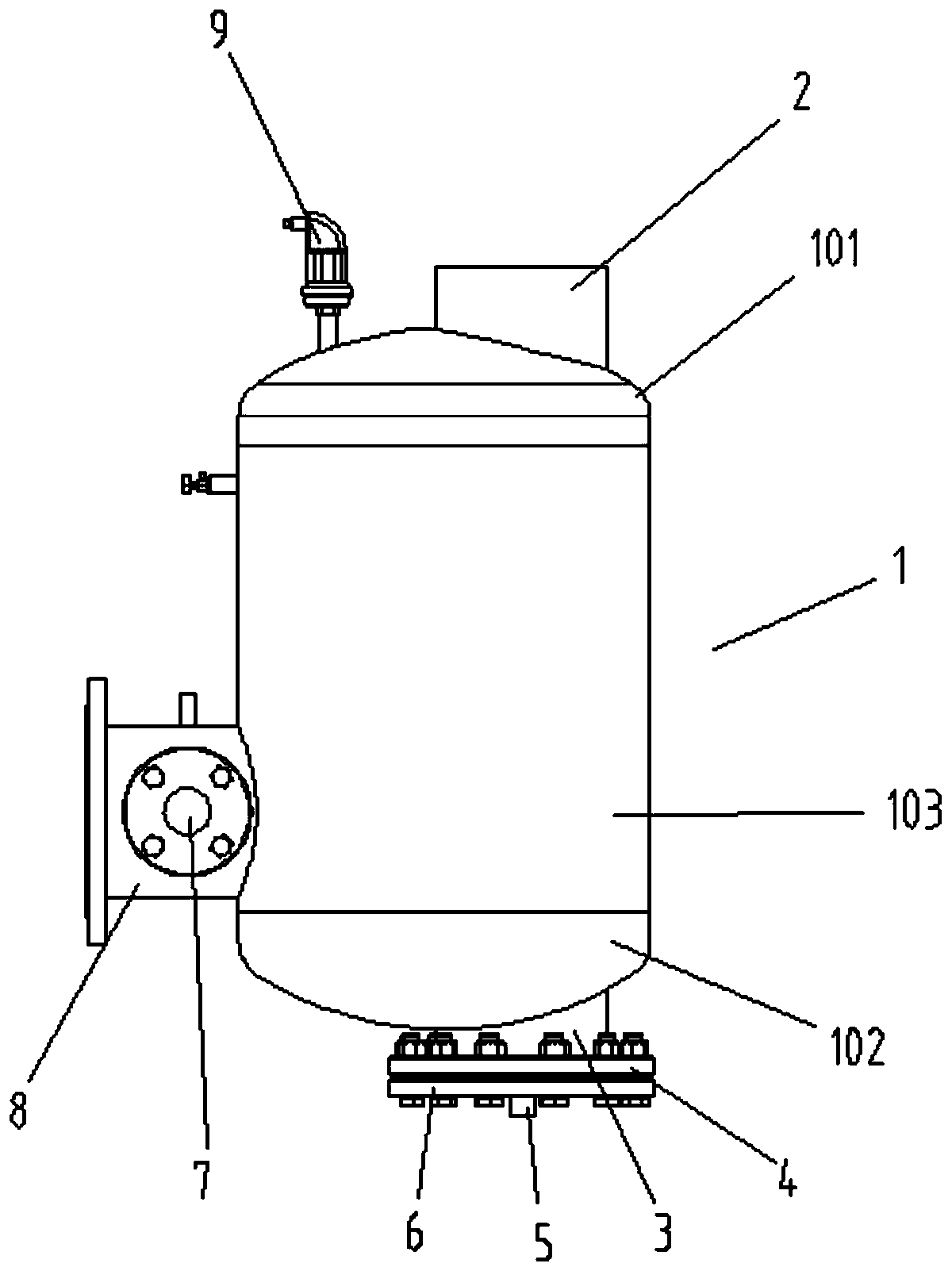

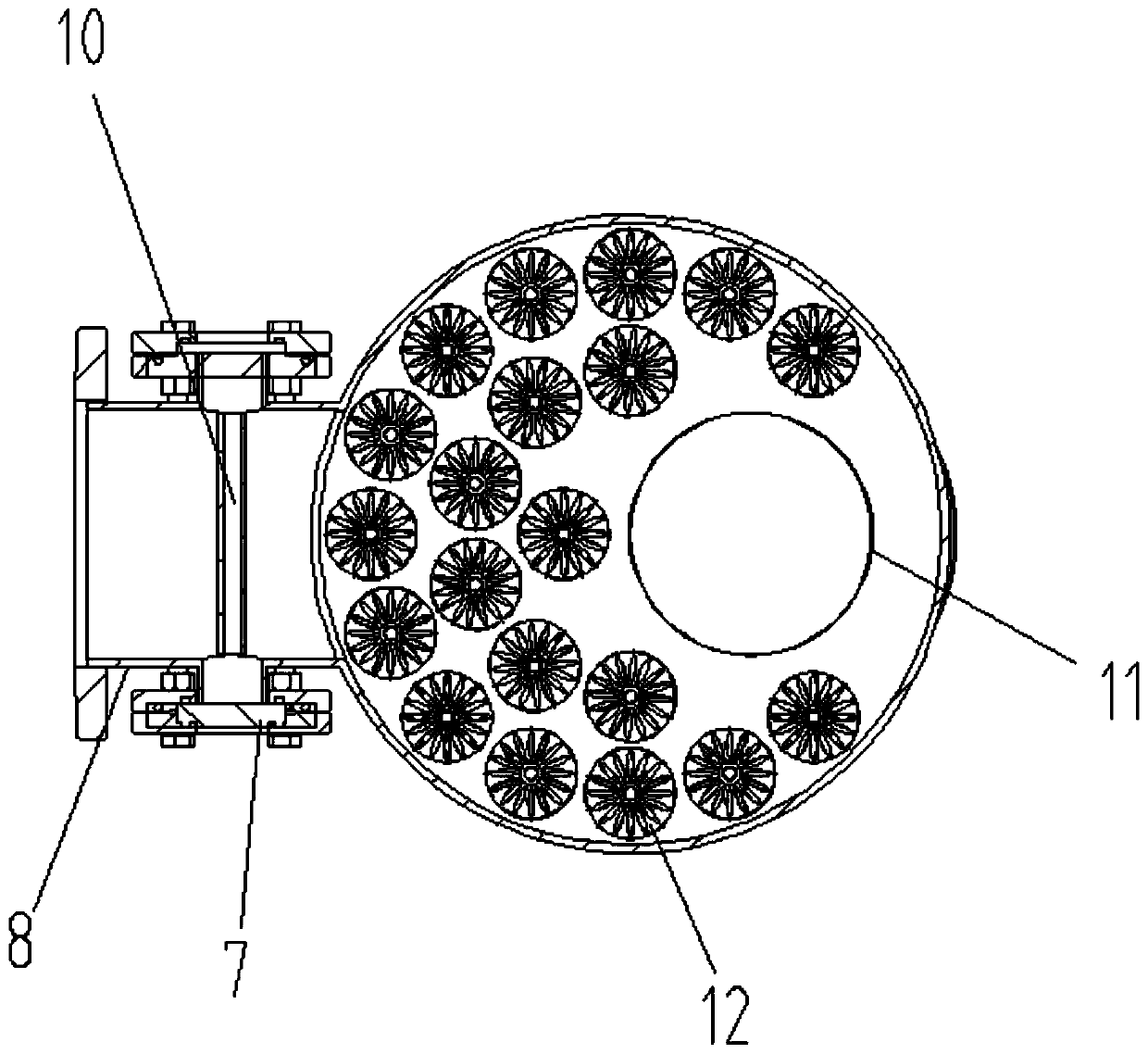

[0025] like Figure 1-4 As shown, the decontamination exhaust device includes a water inlet pipe 2 arranged on the upper part of the main body 1, and the main body 1 includes an upper cover 101, a lower cover 102 and a cylinder body 103, and the upper cover 101. The lower cover 102 is respectively sealed and connected to the upper and lower ends of the cylinder body 103. The top of the upper cover 101 is equipped with an automatic exhaust valve 9 for removing the gas in the inner cavity of the main body 1. The water inlet pipe 2 is installed On the top of the upper cover 101, and on one side of the automatic exhaust valve 9, the side wall of the main body 1 is horizontally provided with a water outlet pipe 8, and a pipe for observing the inner cavity of the main body 1 is installed on the pipe wall of the water outlet pipe 8. Sight glass 7, the bottom of the main body 1 is provided with a sewage pipe 3, the sewage pipe 3 is arranged along the horizontal central axis of the mai...

Embodiment 2

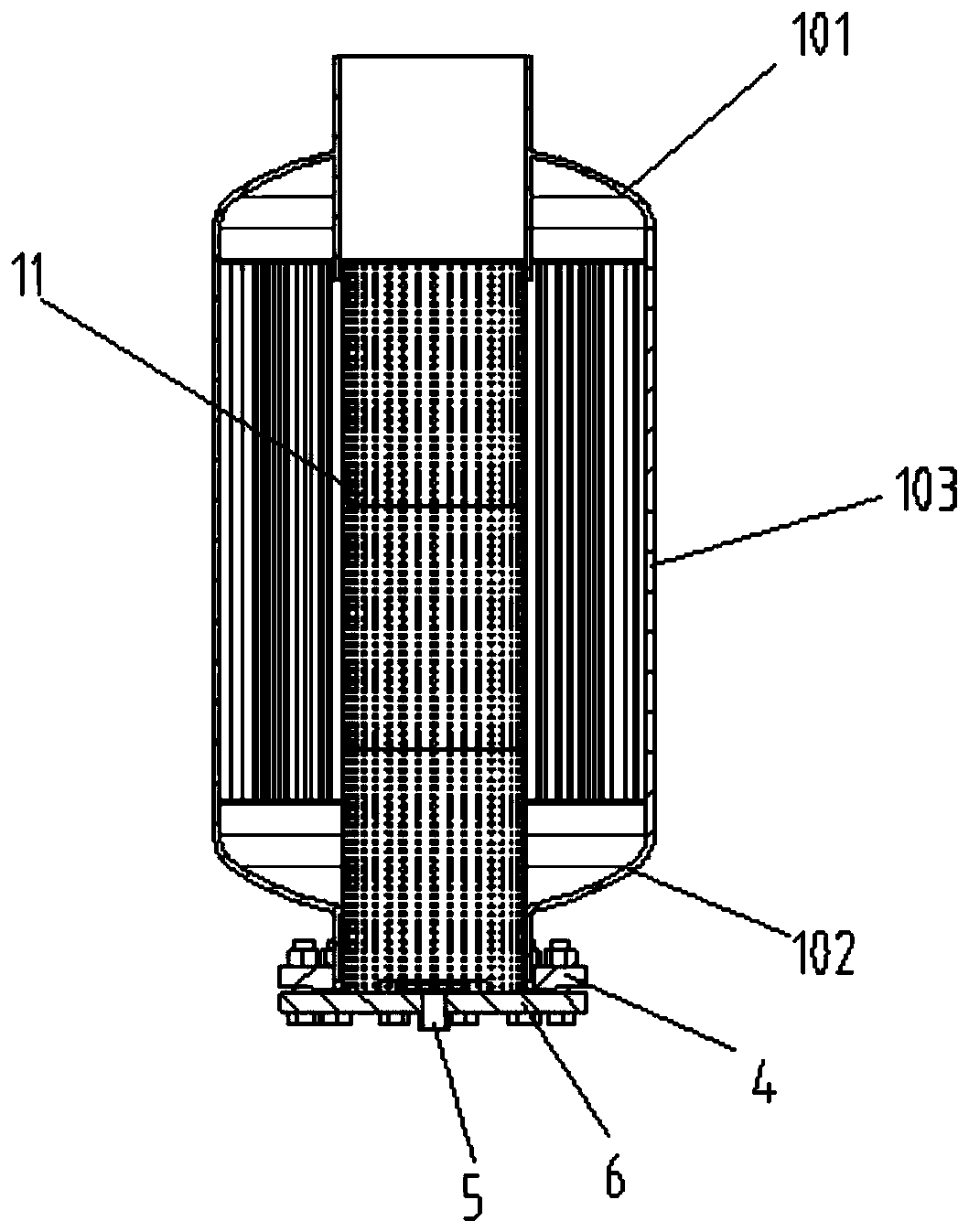

[0033] like Figure 5-7 As shown, the decontamination exhaust device includes a water inlet pipe 2 arranged on the upper part of the main body 1, and the main body 1 includes an upper cover 101, a lower cover 102 and a cylinder body 103, and the upper cover 101. The lower cover 102 is respectively sealed and connected to the upper and lower ends of the cylinder body 103. The top of the upper cover 101 is equipped with an automatic exhaust valve 9 for removing the gas in the inner cavity of the main body 1. The water inlet pipe 2 is installed On one side of the cylinder body 103, the pipeline design of this kind of water inlet pipe 2 can be applied to the tubular installation requirements of various pipelines; A speculum 7 for observing the inner cavity of the main body 1 is installed on the top. The bottom of the main body 1 is provided with a sewage pipe 3. The sewage pipe 3 is arranged along the horizontal central axis of the main body 1 and the water outlet pipe 8, and is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com