Method for reducing odor of hemp fiber composite material and improving strength of hemp fiber composite material

A composite material and hemp fiber technology, applied in fiber treatment, plant fiber, superstructure sub-assembly, etc., can solve the problems of poor strength, easy water absorption, bad smell, etc., achieve high strength, reduce odor, and avoid weight gain Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] The hydrophobic agent and water are formulated into an aqueous solution according to the ratio of 1:100.

[0021] 10-20cm chopped natural hemp fibers are soaked in the aqueous solution for 10 minutes until the hemp fibers are completely soaked in the aqueous solution, and the soaked hemp fibers are dehydrated with a centrifuge to control the moisture content of the hemp fibers at about 50%, and then put The dehydrated hemp fiber is dried to control the moisture content at about 10% to obtain the modified hemp fiber.

[0022] The modified hemp fiber and the 10-20cm chopped polypropylene fiber are mixed and processed to form the modified hemp fiber composite material.

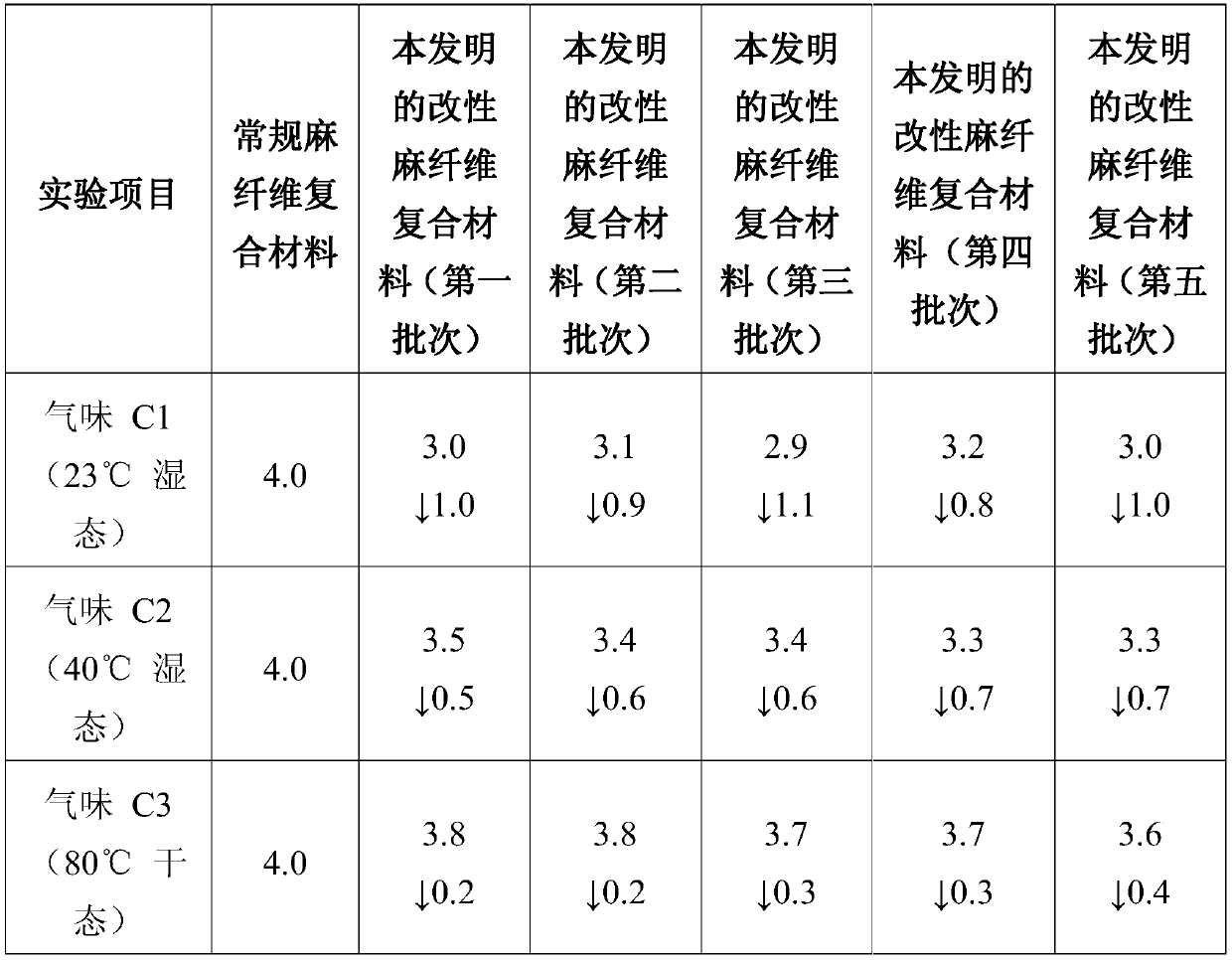

[0023] A total of five batches of modified hemp fiber composite materials were obtained, and the corresponding odor verification data are shown in Table 1 below:

[0024] Table 1

[0025]

[0026] Apparently, the modified hemp fiber composite according to the invention has significantly improved low o...

Embodiment 2

[0032] Mix the water-repellent agent and water according to the ratio of 1:50 to make an aqueous solution.

[0033] The chopped natural hemp fiber is soaked in the aqueous solution for 20 minutes until the hemp fiber is completely soaked in the aqueous solution, and the soaked hemp fiber is dehydrated with a centrifuge to control the moisture content of the hemp fiber at about 50%, and then the dehydrated hemp fiber is The hemp fiber is dried, and the moisture content is controlled at about 10% to obtain the modified hemp fiber.

[0034] The modified hemp fiber and the chopped polypropylene fiber are mixed and processed to form a modified hemp fiber composite material.

Embodiment 3

[0036] The chopped natural hemp fiber and the chopped polypropylene fiber are mixed and processed to form the hemp fiber composite material.

[0037] The hydrophobic agent and water are formulated into an aqueous solution according to the ratio of 1:100.

[0038] Use the aqueous solution to spray the hemp fiber composite material to control the moisture content of the hemp fiber composite material to about 50%, and then dry the hemp fiber composite material to control the moisture content of the hemp fiber composite material below 5% to obtain modified hemp fiber composite material. fiber composites.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com