Anchor cable base

An anchor cable base and support plate technology, which is applied in foundation structure engineering, sheet pile wall, excavation and other directions, can solve problems such as shortening the service life of anchor cables, and achieve the effect of ensuring accuracy and avoiding shearing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

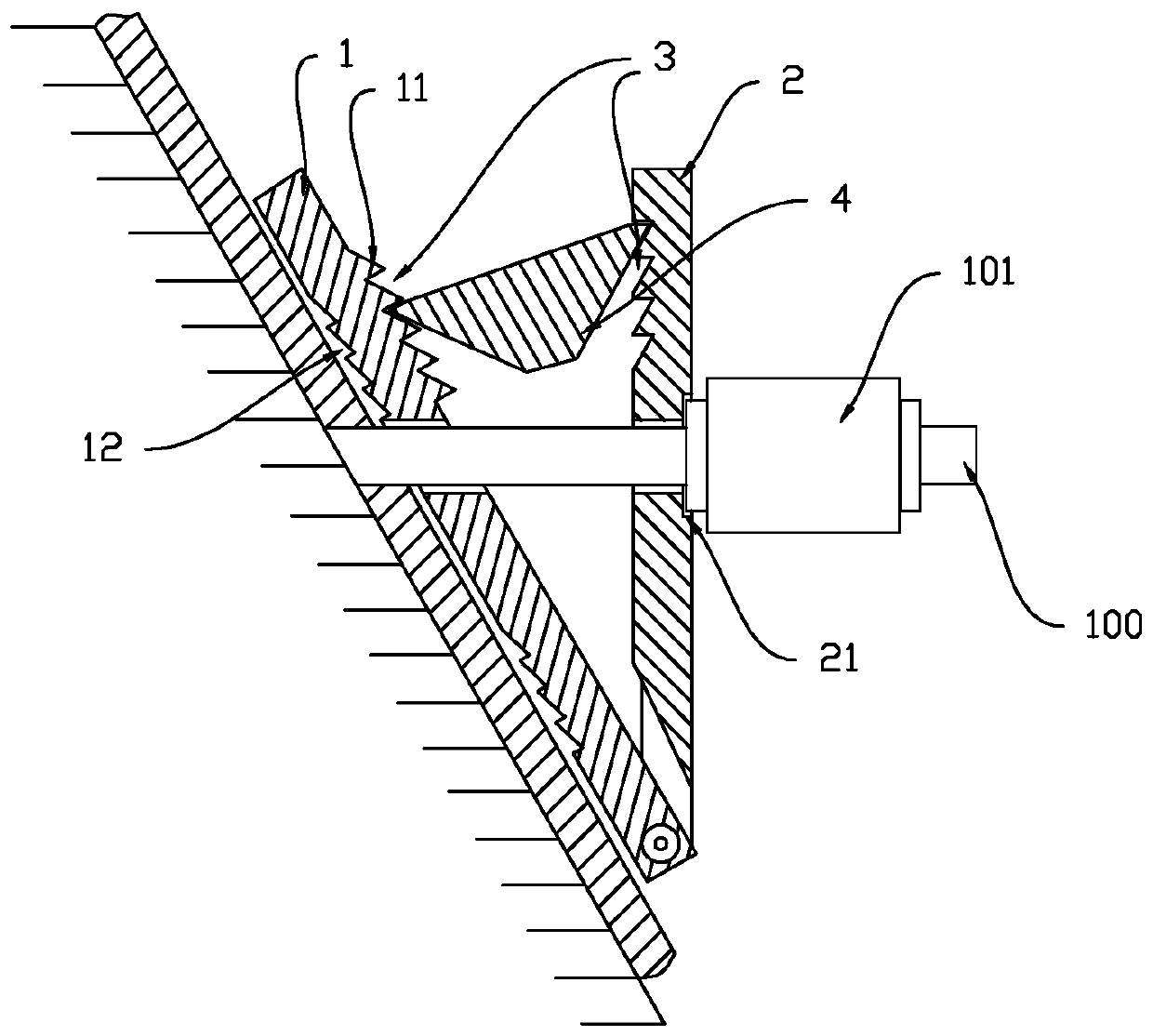

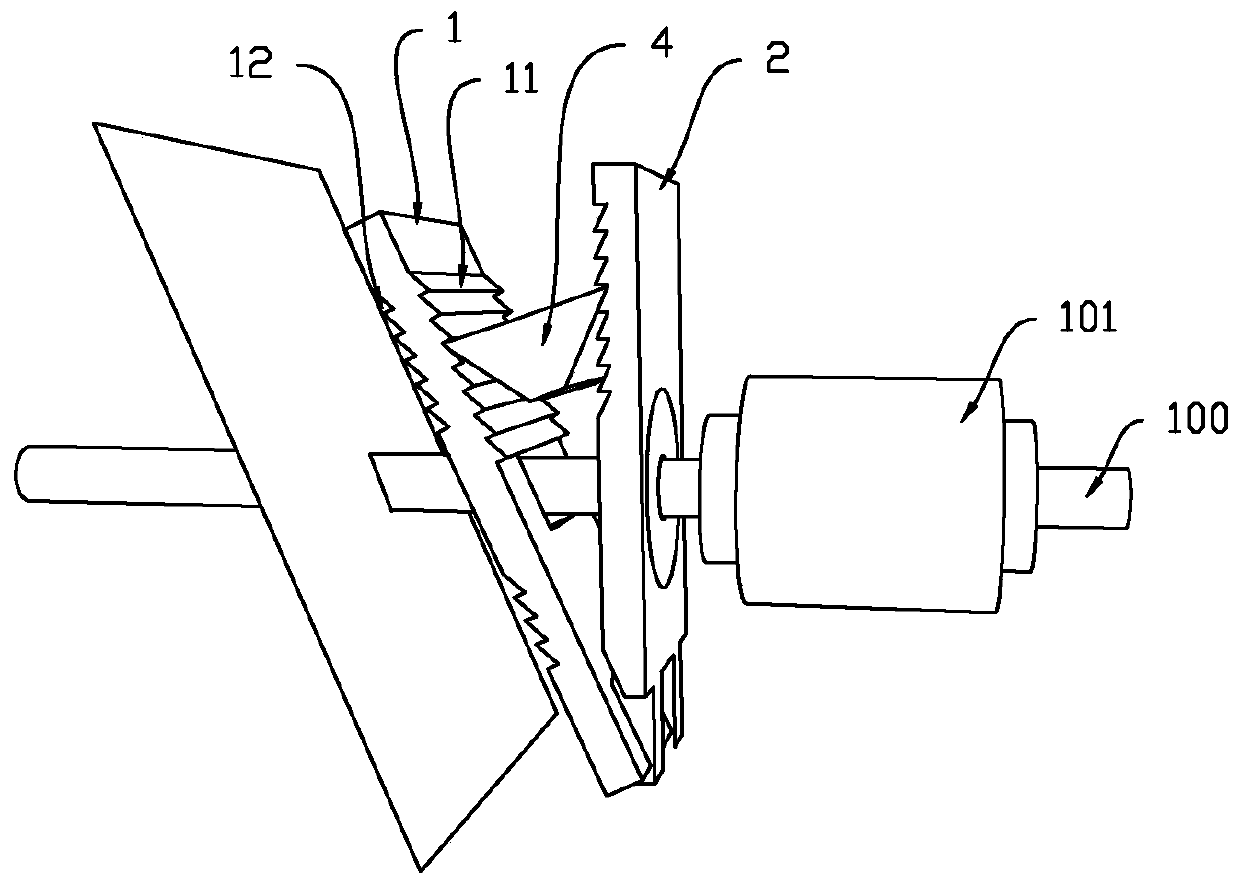

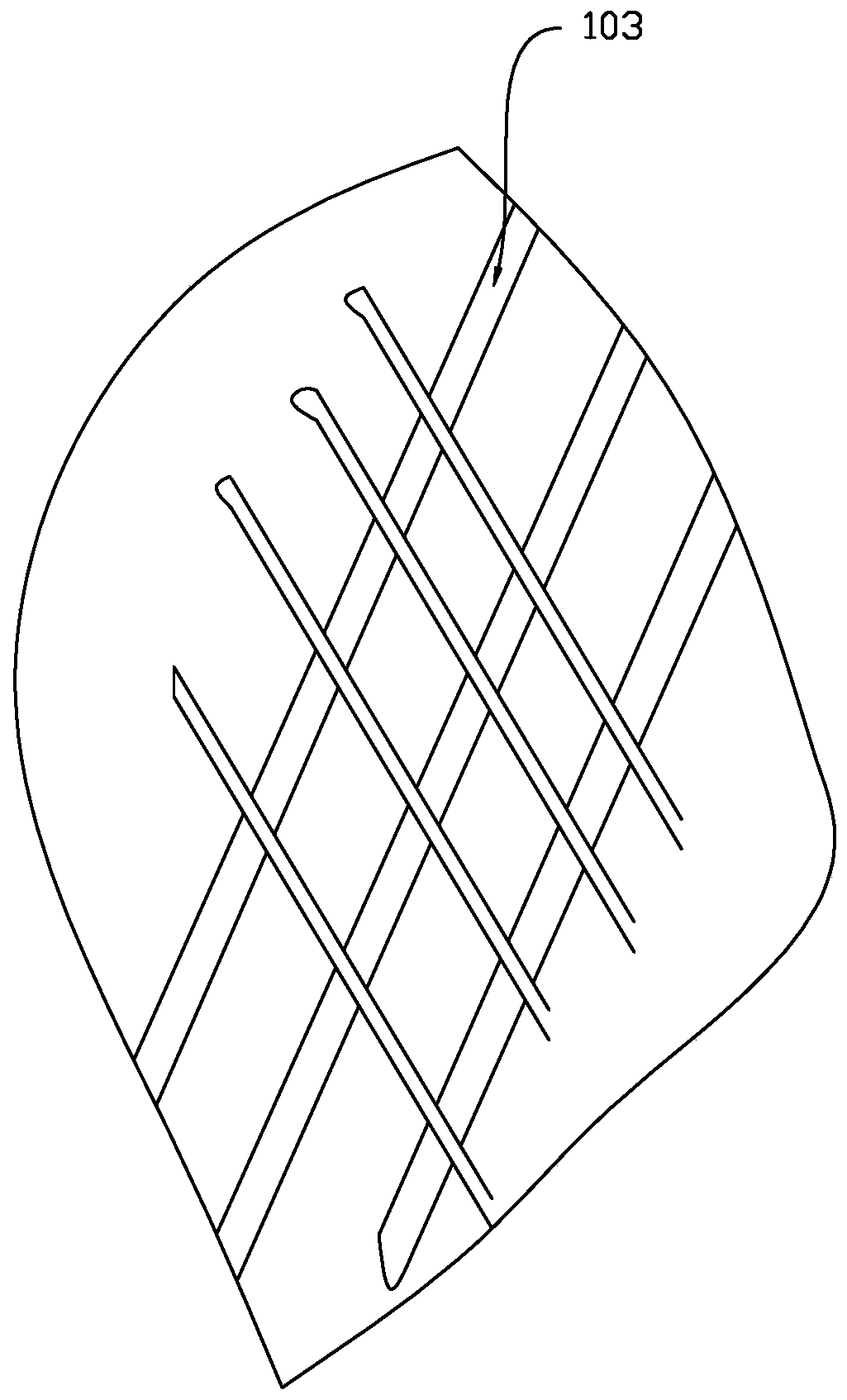

[0018] refer to Figure 1 ~ Figure 3 , the present embodiment adopts lattice beam support 103, including several protection beams intersecting horizontally and vertically. The bottom plate 1 and the support plate 2 are provided with through holes for passing the anchor cable 100, the side of the bottom plate 1 away from the support plate 2 is provided with a friction structure to increase friction, and an angle is set between the bottom plate 1 and the support plate 2 The adjustment device, the angle adjustment device includes a number of toothed grooves 3 respectively arranged on the opposite surfaces of the bottom plate 1 and the support plate 2 , and also includes an adjustment wedge 4 whose two ends are respectively clamped in a toothed groove 3 .

[0019] On this anchor cable base, the anchor cable 100 passes through the through holes on the base plate 1 and the support plate 2, and the anchor 101 is provided at the end of the anchor cable 100. When the anchor cable 100 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com