High-voltage coil air passage placing structure

A high-voltage coil and air channel technology, applied in the direction of transformer/inductor coil/winding/connection, electrical components, transformer/inductor components, etc., can solve the problems of reducing product quality, transformer overheating, etc., to improve product quality, The effect of preventing local overheating and reducing coil winding man-hours

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

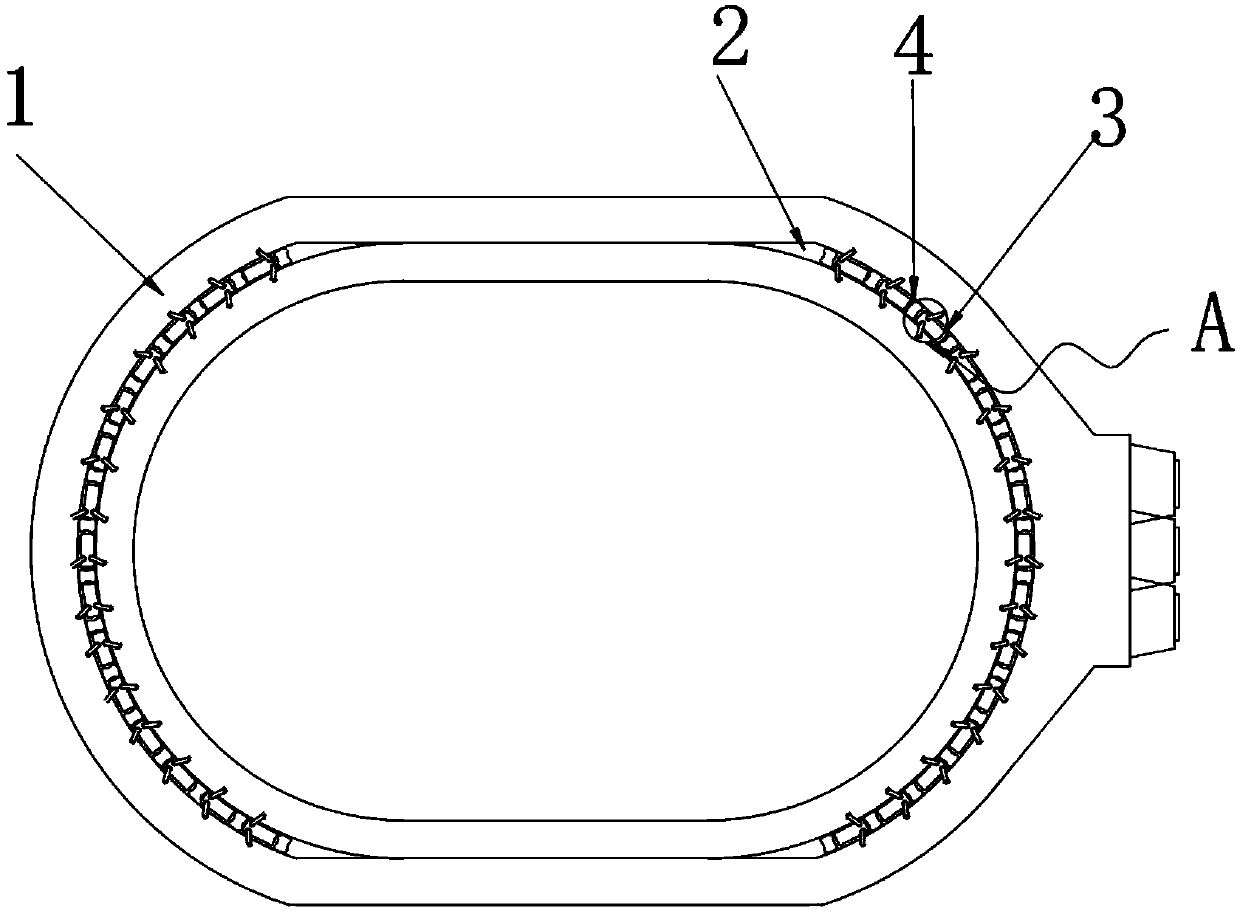

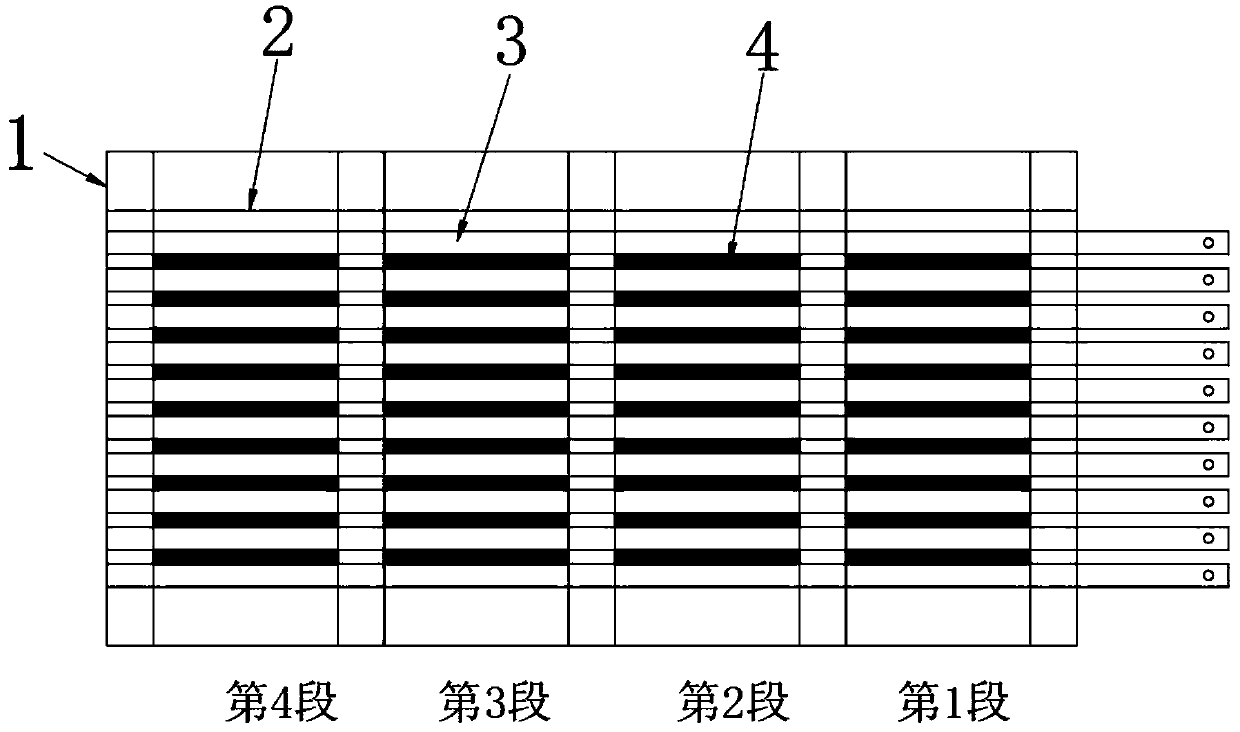

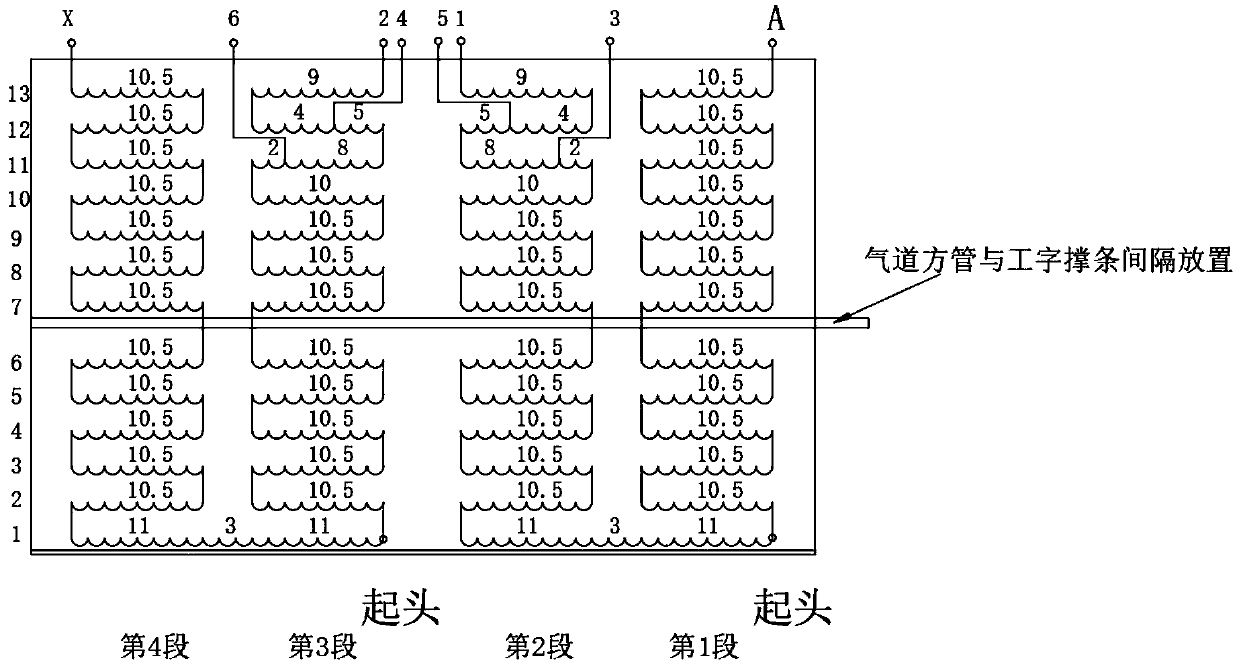

[0024] see Figure 1-5 , the application provides a technical solution: a high-voltage coil airway placement structure, including a high-voltage coil 1 and an airway 2, the front surface of the high-voltage coil 1 is provided with a through airway 2, and an airway square tube is installed in the airway 2 3. The airway square tube 3 is fixedly connected to the high-voltage coil 1. The side of the airway 2 close to the airway square tube 3 is equipped with an I-shaped stay 4. The I-shaped stay 4 is fixedly connected to the high-voltage coil 1. The airway square tube The inner side wall of 3 is provided with a first rotating shaft 5, and the first rotating shaft 5 is fixedly connected with the airway square tube 3, and the front end of the first rotating shaft 5 is provided with a first fixing plate 6, and the first fixing plate 6 is rotationally connected with the first rotating shaft 5, The first fixed plate 6 is provided with a female button 7 on the inner wall of one end away...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com