High-pressure water lubrication compressor

A water-lubricated and compressor technology, applied in the field of compressors, can solve the problems of compressor axial force imbalance, bearing damage, rotor cannot reach high speed, etc., and achieve a stable balance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] In order to make the purpose, technical solution and advantages of the present application clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. In the ensuing description some specific details are referred to for a thorough understanding of the present invention. While the present invention can be practiced without these specific details, the description and representations herein can be used by those skilled in the art to more effectively convey the substance of their work to others skilled in the art.

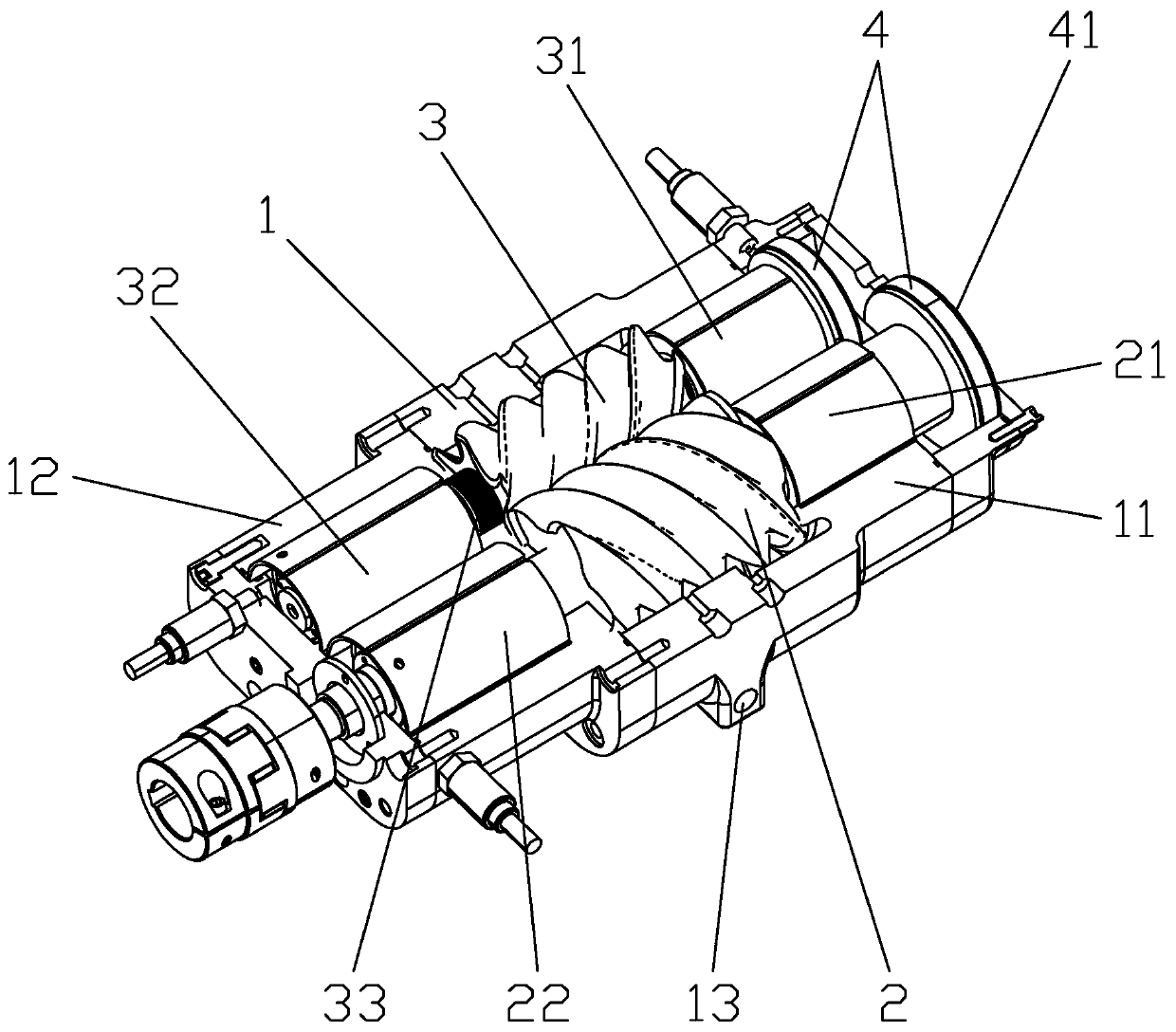

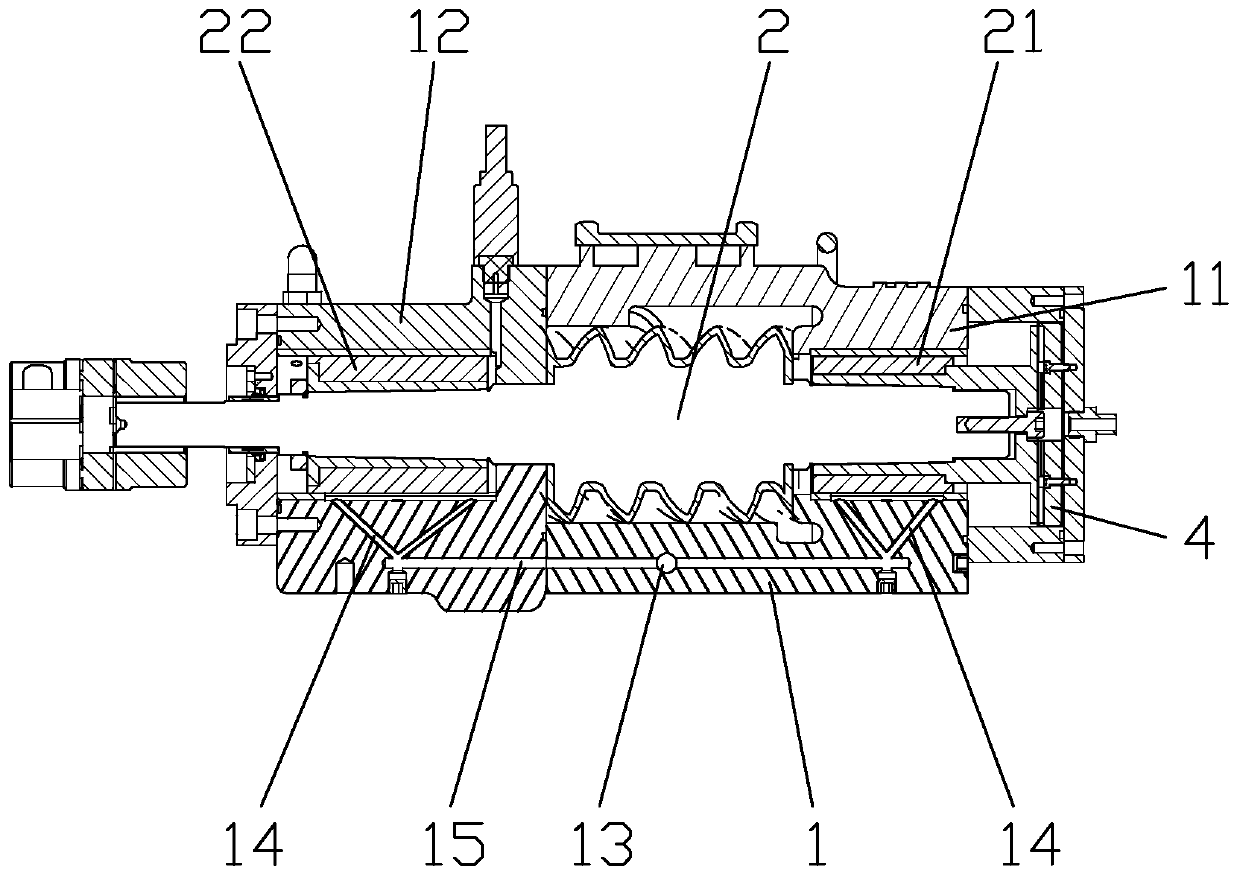

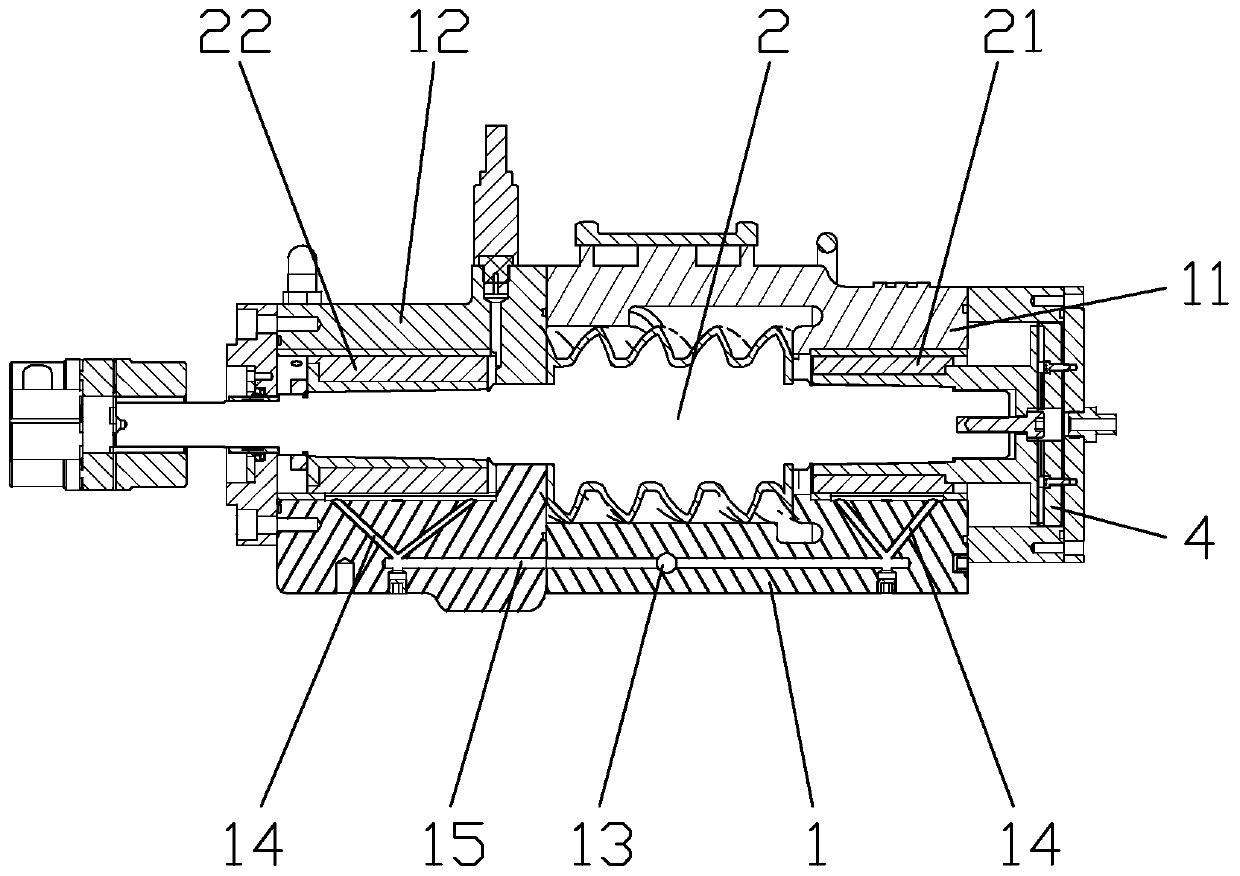

[0013] refer to figure 1 , figure 2 , a high-pressure water-lubricated compressor, including a casing 1, the casing 1 includes a suction side bearing seat 11, and a discharge side bearing seat 12, and the casing 1 has a built-in male rotor 2 and a female rotor 3, wherein the male The rotor 2 is fitted with a water-lubricated radial sliding bearing 21 on the suction side of the male ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com