Track switch filler detection ruler

A technology for measuring rulers and turnouts, which is applied in the field of measuring rulers, can solve problems such as ineffective control of product quality, unreliable stability and accuracy, and poor adaptability of measuring tools, so as to achieve convenience for production and maintenance workers and good adaptability , Improve the detection accuracy and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

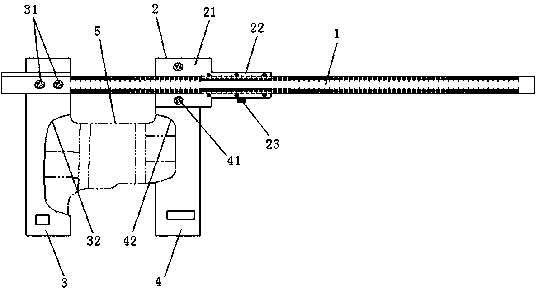

[0024] like figure 1 As shown, the switch interval iron detection ruler of the present invention includes a main ruler 1 , a vernier ruler 2 , a left measuring claw 3 and a right measuring claw 4 .

[0025] The main ruler 1 is a rectangular strip structure, and two rows of main ruler scales are symmetrically arranged on the front upper side and the front lower side along the length direction.

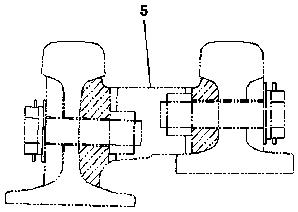

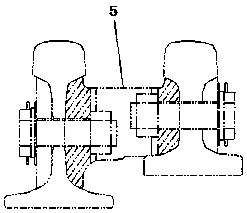

[0026] The vernier scale 2 is slidingly fitted with the main scale 1, and it includes a rectangular base 21 and a rectangular measuring portion 22 connected to the middle of one end of the base; the upper and lower sides of the front of the measuring portion 22 are symmetrically fixed with a pair of upper and lower sides by screws. Symmetrically arranged slideways spaced apart from each other, the measuring part 22 is connected to the main scale 1 through a sliding fit through the upper and lower slideways, and the outer walls of the upper and lower slideways of the measuring part 22 ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com