Point heat source mobile distributed seepage monitoring system and its monitoring method

A monitoring system and distributed technology, applied in measurement devices, permeability/surface area analysis, suspension and porous material analysis, etc., can solve problems such as affecting the monitoring accuracy, unable to eliminate the effect of seepage direction, and increasing measuring points, etc. Spatial resolution problem, meeting long-term monitoring needs, and avoiding the effect of failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

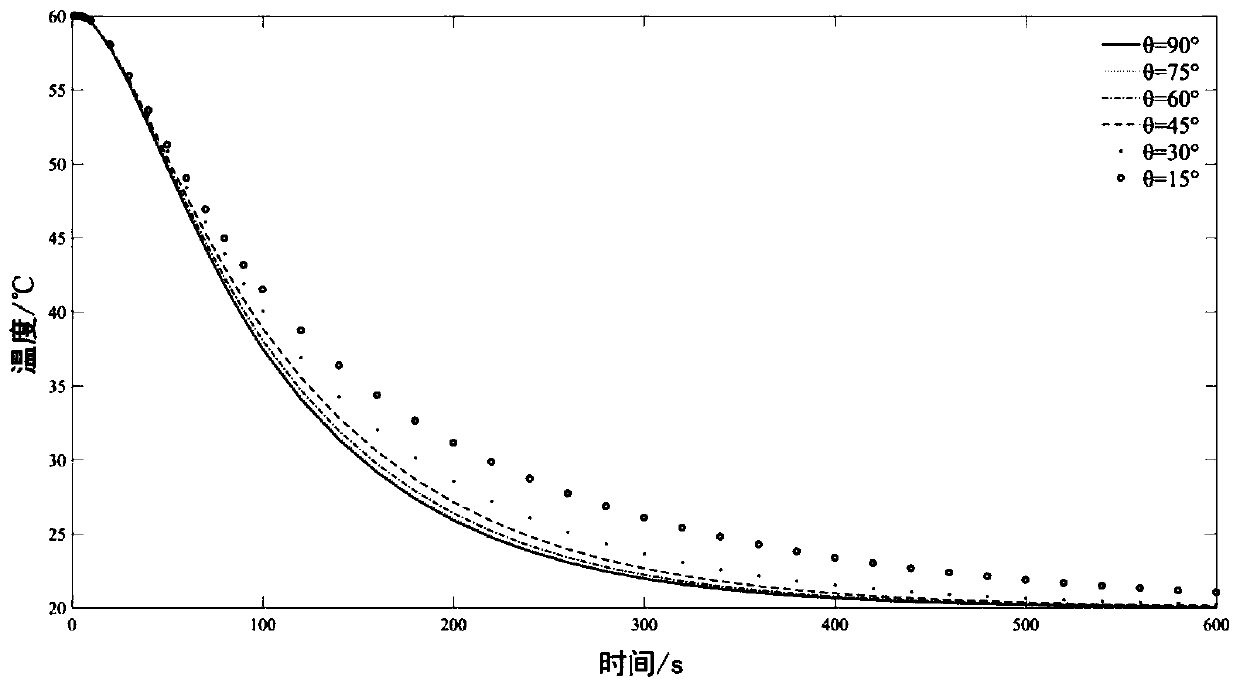

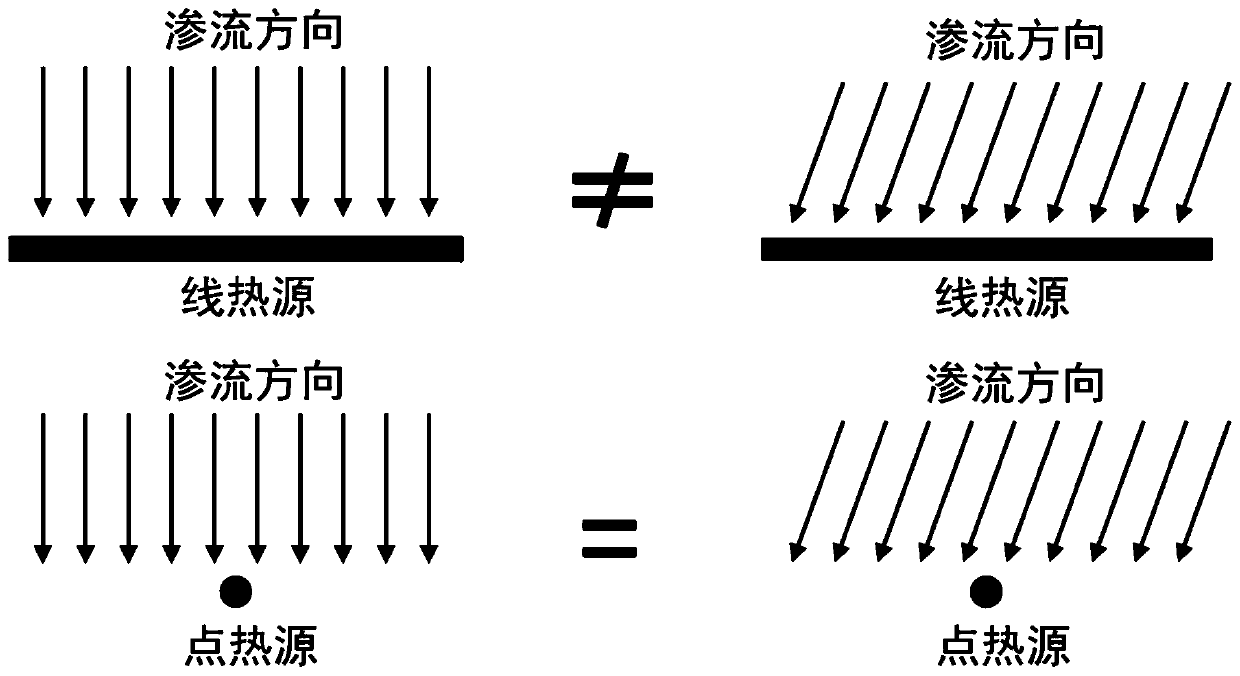

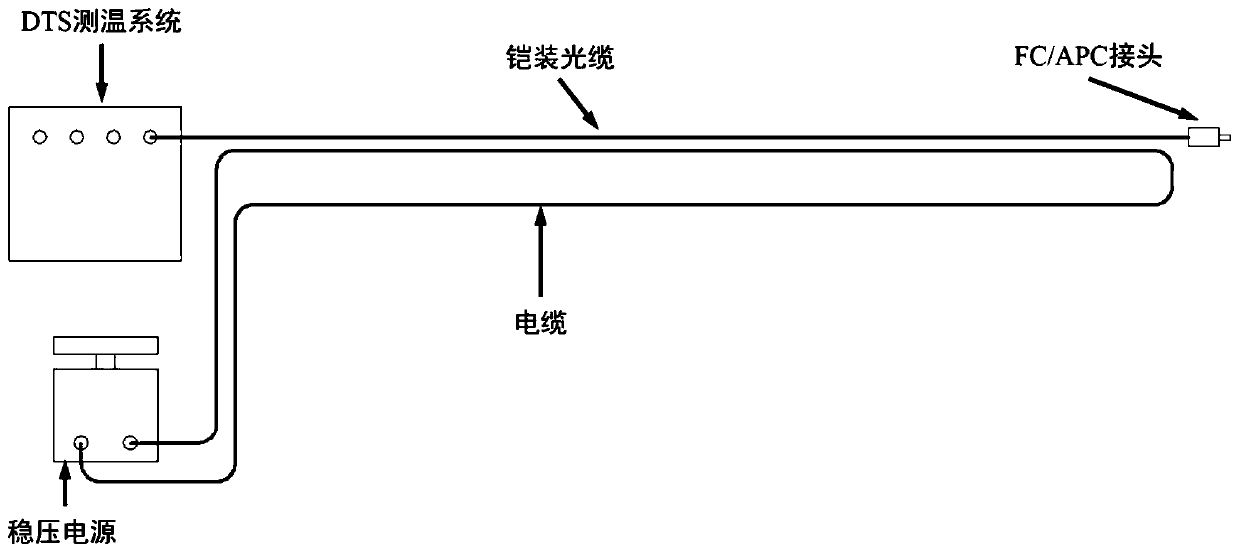

[0063] In order to verify the effectiveness of the point heat source seepage monitoring system developed by the present invention, a Figure 9The test model shown (H1=100mm, H2=600mm, H3=600mm, B=300mm, L=800mm), under the influence of dual factors of seepage velocity and seepage direction, the calibration test was carried out. The shell of the model box is spliced by 3mm thick steel plates, and a square steel pipe frame is set outside the box as a lateral support. There are 4 drain pipes at the bottom of the box, and valves are installed on the drain pipes to control the flow. Embed 4 monitoring pipes 7 (PE-RT pipes, outer diameter 20mm, wall thickness 2mm) in the box, the axis and the infiltration direction (from top to bottom) are respectively 90°, 70°, 50°, 30° °. First, lay 10cm-thick gravel at the bottom of the box as a reverse filter layer, and then fill in river sand to the design elevation. Before filling the river sand, put a steel bar in the monitoring pipe 7 i...

Embodiment 2

[0069] On the basis of Example 1, using Figure 8 In the improved scheme shown, pure water is poured into the monitoring pipe 7 to carry out calibration tests at different seepage velocities. Each working condition ln(λ-λ θ ) vs. time curve, see Figure 11 . It can be seen that as the seepage velocity increases, the temperature drops faster, and ln(λ-λ θ ) has a strong correlation with the seepage velocity. According to ln(λ-λ θ ) time history curve, and divide it into three stages: rapid cooling period (0-200s), transitional period (200s-300s), and slow cooling period (300s-temperature stable). In the fast cooling section and the slow cooling section, ln(λ-λ θ ) time history curve is approximately linear, using the data from 50s to 200s and 300s to 600s respectively to fit ln(λ-λ θ ) The slope ξ of the time history curve in these two periods v1 and ξ v2 , as shown in Table 2. ξ v1 and ξ v2 The absolute values of both increase with the increase of the seepage vel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com