Busbar capable of preventing thermal runaway diffusion and storage battery pack

A battery pack and busbar technology, which is applied to battery pack components, secondary batteries, secondary battery repair/maintenance, etc., can solve the problem of high connection resistance of single batteries, affecting power battery performance, and battery pack rate performance decline, etc. problem, to avoid the effect of spreading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

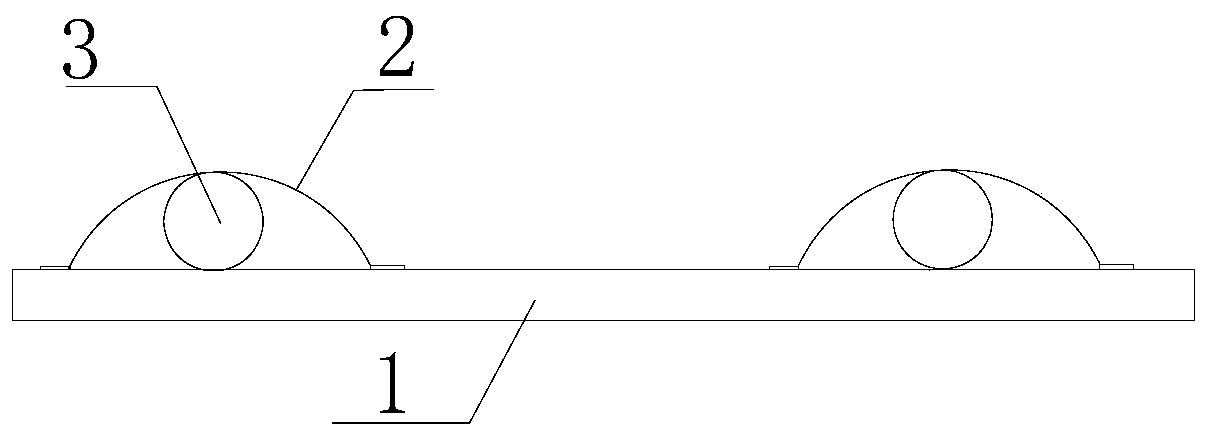

[0035] 20 18650 batteries are connected in parallel to form a battery pack. The metal Al is used as the bus bar. The 18650 battery and the bus bar are connected through the Al sheet, and a cavity is left between the Al sheet and the bus bar (such as figure 1 shown), fill the cavity between the Al sheet and the bus bar with ammonium nitrate.

[0036] After thermal runaway occurred in one 18650 battery in the battery pack, the high temperature spread rapidly from the upper cover of the battery along the Al sheet, and the temperature of the Al sheet increased causing ammonium nitrate to explode, cutting off the connection between the Al sheet and the bus bar to prevent thermal runaway Diffusion along the busbar.

Embodiment 2

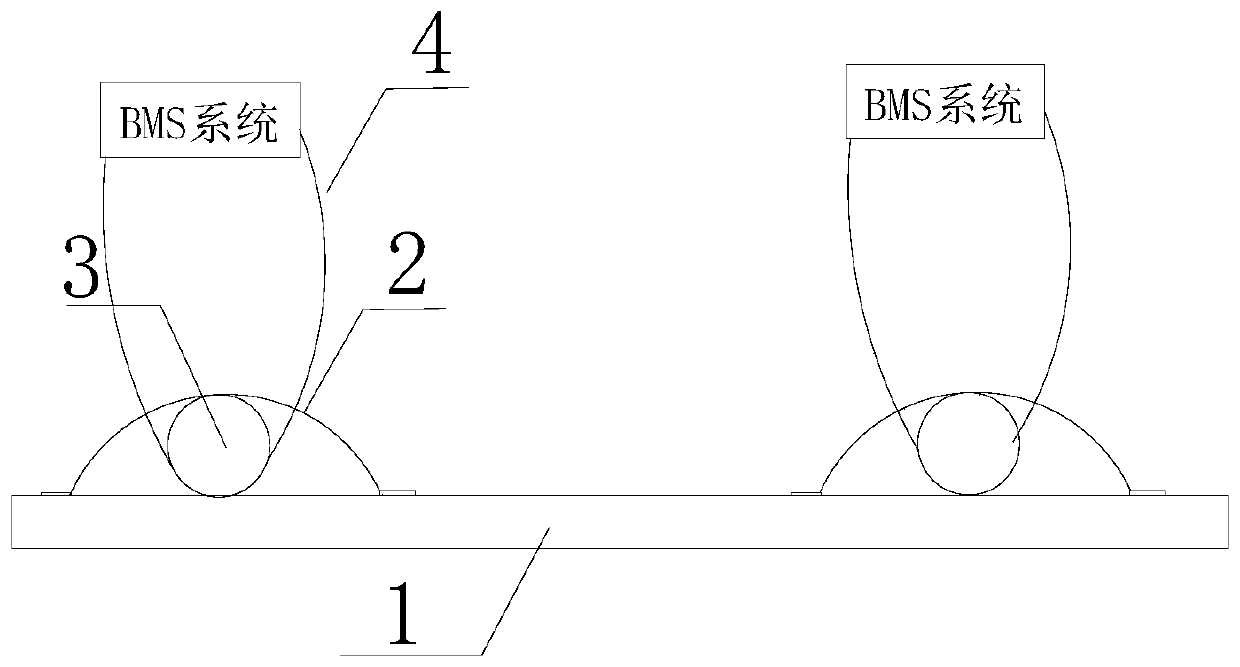

[0038] 20 18650 batteries are connected in parallel to form a battery pack, and the metal Al is used as a bus bar. The 18650 battery and the bus bar are connected through an Al sheet, and a cavity is left between the Al sheet and the bus bar. NaN 3 After being mixed with a binder, it is pressed on the surface of the heating wire 4, and then put into the cavity between the Al sheet and the bus bar, and the two ends of the heating wire are connected to the BMS system.

[0039] The BMS monitors the operating status of the battery pack. When it is found that a 18650 battery has an internal short circuit or is about to experience thermal runaway, the BMS system will power up the heating wire to trigger NaN 3 Decomposition occurs, and the Al sheet is cut off from the busbar to prevent thermal runaway from spreading along the busbar.

Embodiment 3

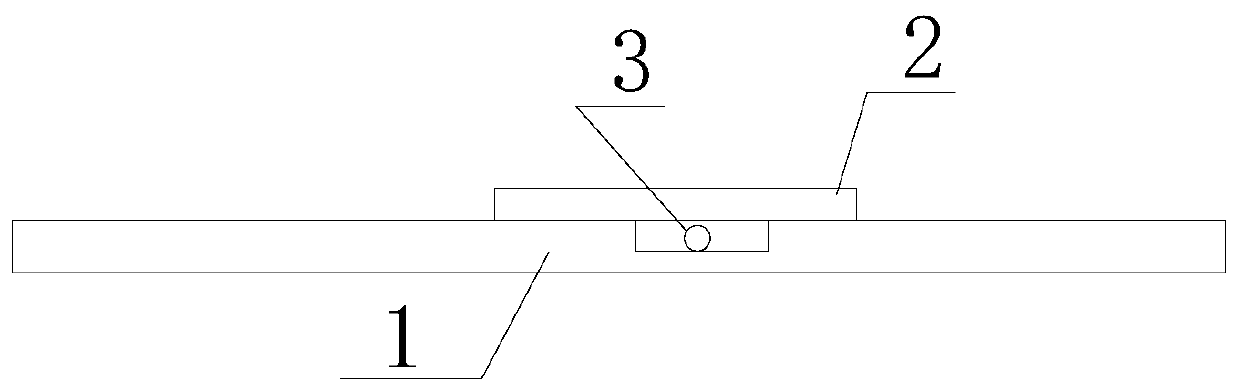

[0041] 20 18650 batteries are connected in parallel to form a battery pack, with metal Cu as the bus bar, the 18650 battery is connected to the bus bar through the Ni strip, and there are pits in the bus bar for filling the mixture of ammonium nitrate and sucrose, and then the Ni sheet is welded above the busbar cavity.

[0042] After a thermal runaway occurred in a 18650 battery, the high temperature spread along the Ni sheet, triggering the explosion of the mixture of ammonium nitrate and sucrose, cutting off the connection between the 18650 battery and the bus bar to prevent the spread of thermal runaway.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com