Linear motor

A linear motor and coil technology, applied in electrical components, electromechanical devices, etc., can solve the problems of smaller outer diameter, loud noise, and larger diameter, and achieve the effects of reducing production processes, simplifying manufacturing, and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

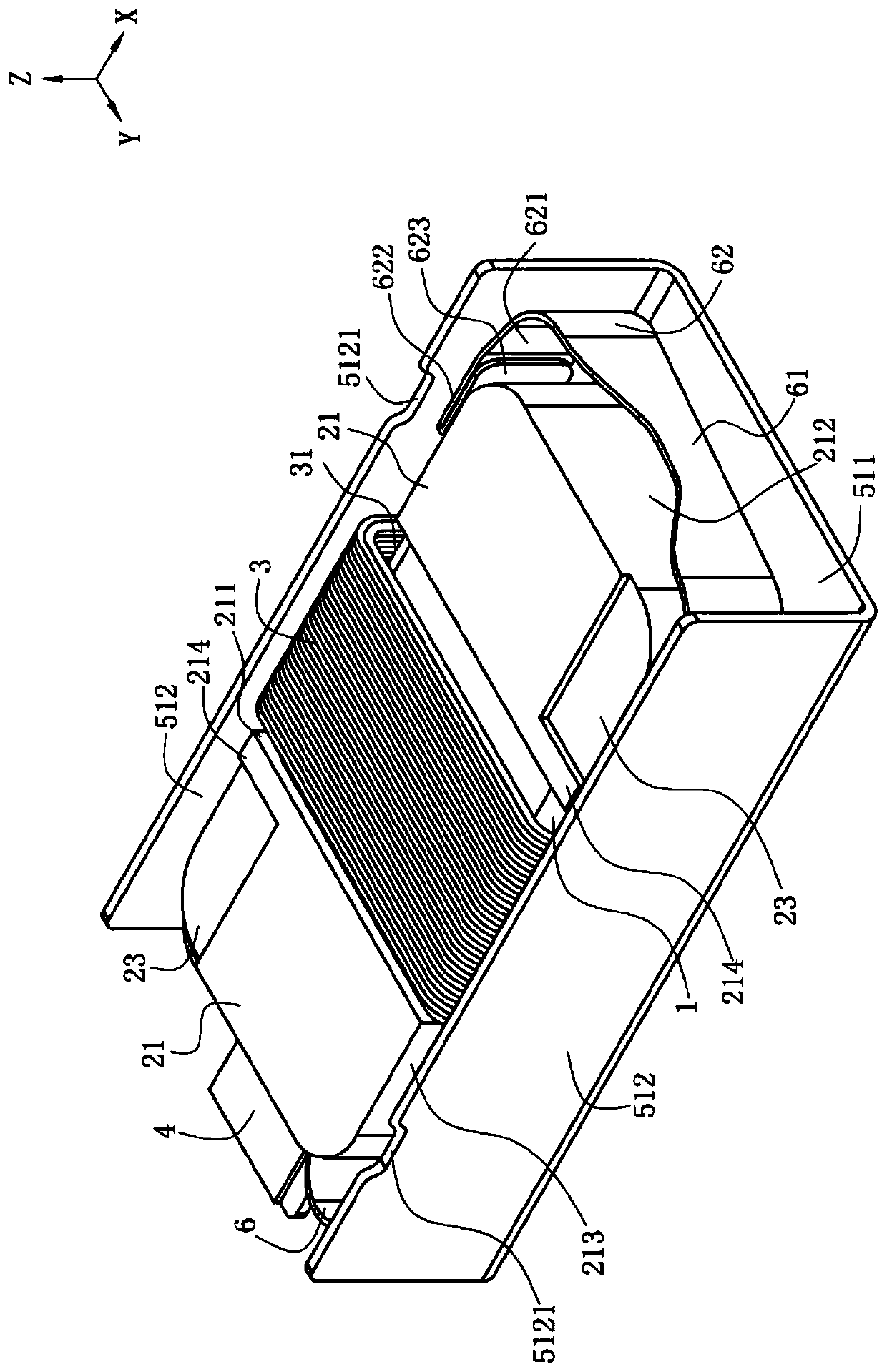

[0033] In order to facilitate a better understanding of the purpose, structure, features, and effects of the present invention, the present invention will now be further described in conjunction with the accompanying drawings and specific embodiments.

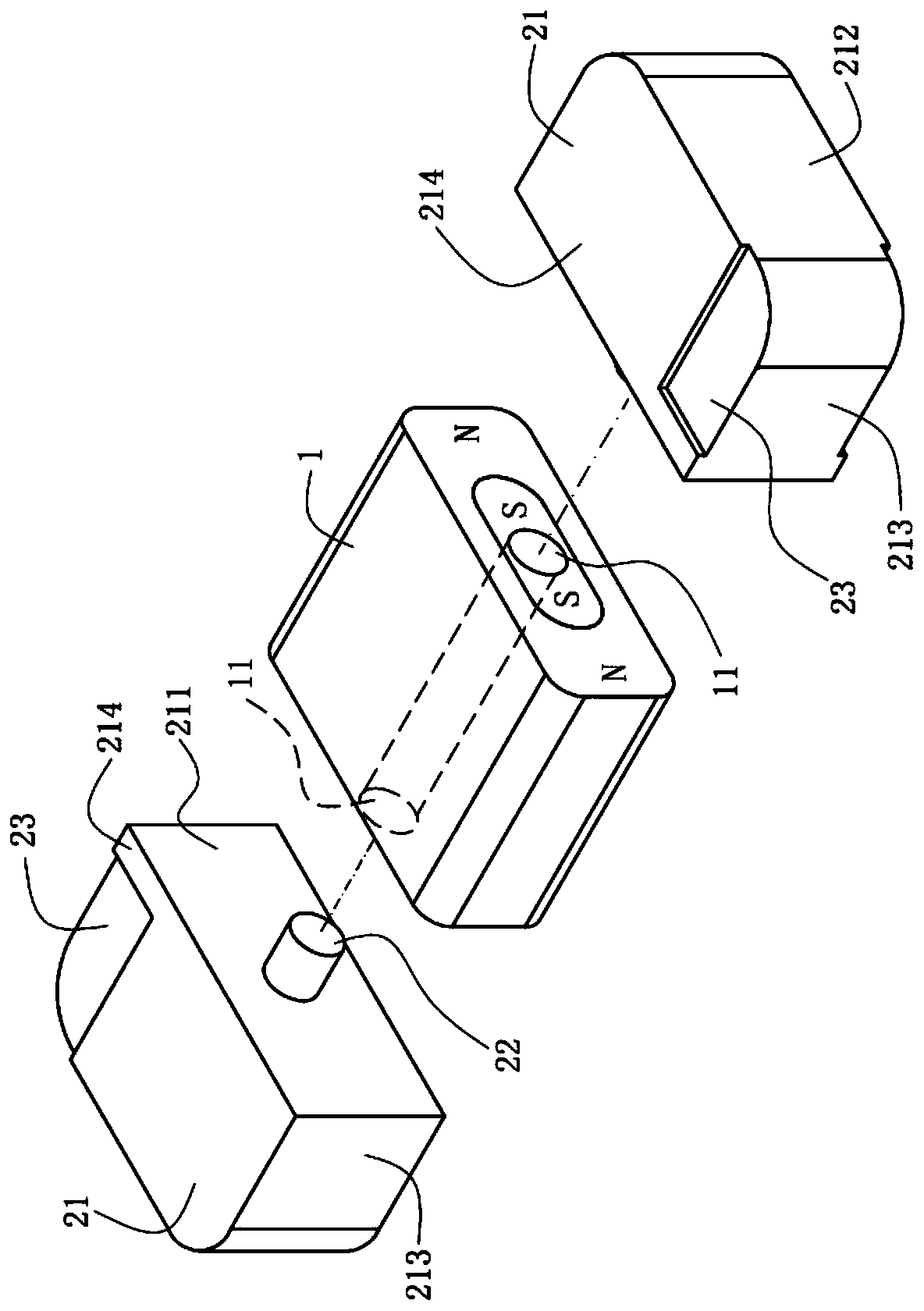

[0034] For ease of description, in this embodiment, the front-back direction (equivalent to the vibration direction) is defined as the X direction, the left-right direction is the Y direction perpendicular to the X direction, and the up-down direction is the Z direction perpendicular to the X direction and the Y direction.

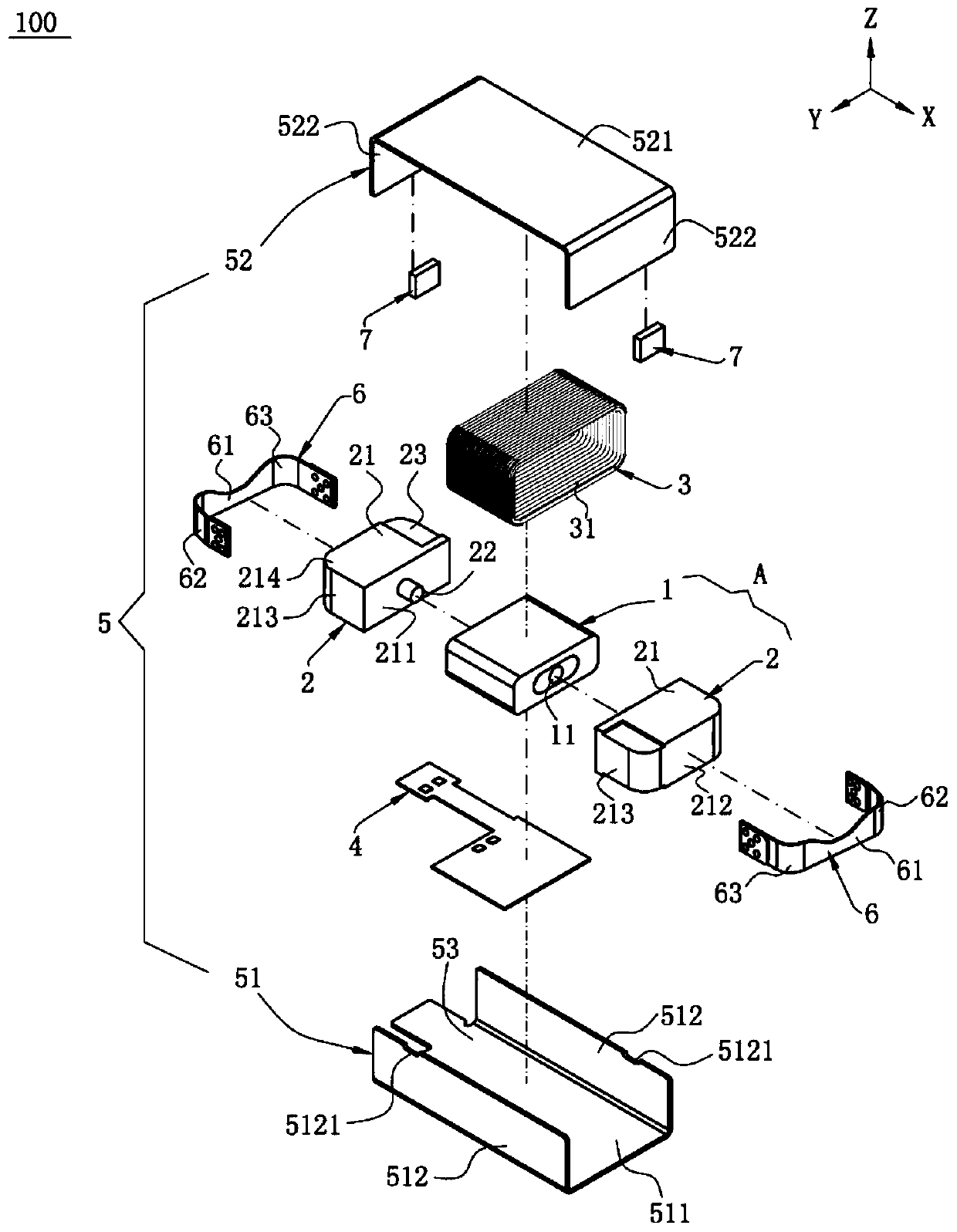

[0035] Please refer to Figure 1 to Figure 7 , is the first embodiment of a linear motor 100 of the present invention, the linear motor 100 includes a mover A (comprising a magnetic element 11 and two masses 2) vibrating along the vibration direction, a coil 3, a circuit board 4 , a housing 5 , two reset members 6 , and two buffer members 7 .

[0036] Please refer to figure 1 , figure 2 and Figure 5 ,...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap