Double-bucket type solid-liquid separator and separation method

A solid-liquid separator, solid-liquid separation technology, applied in the direction of presses, manufacturing tools, etc., can solve problems such as reduced work efficiency, and achieve the effect of improving work efficiency and increasing the speed of juice discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

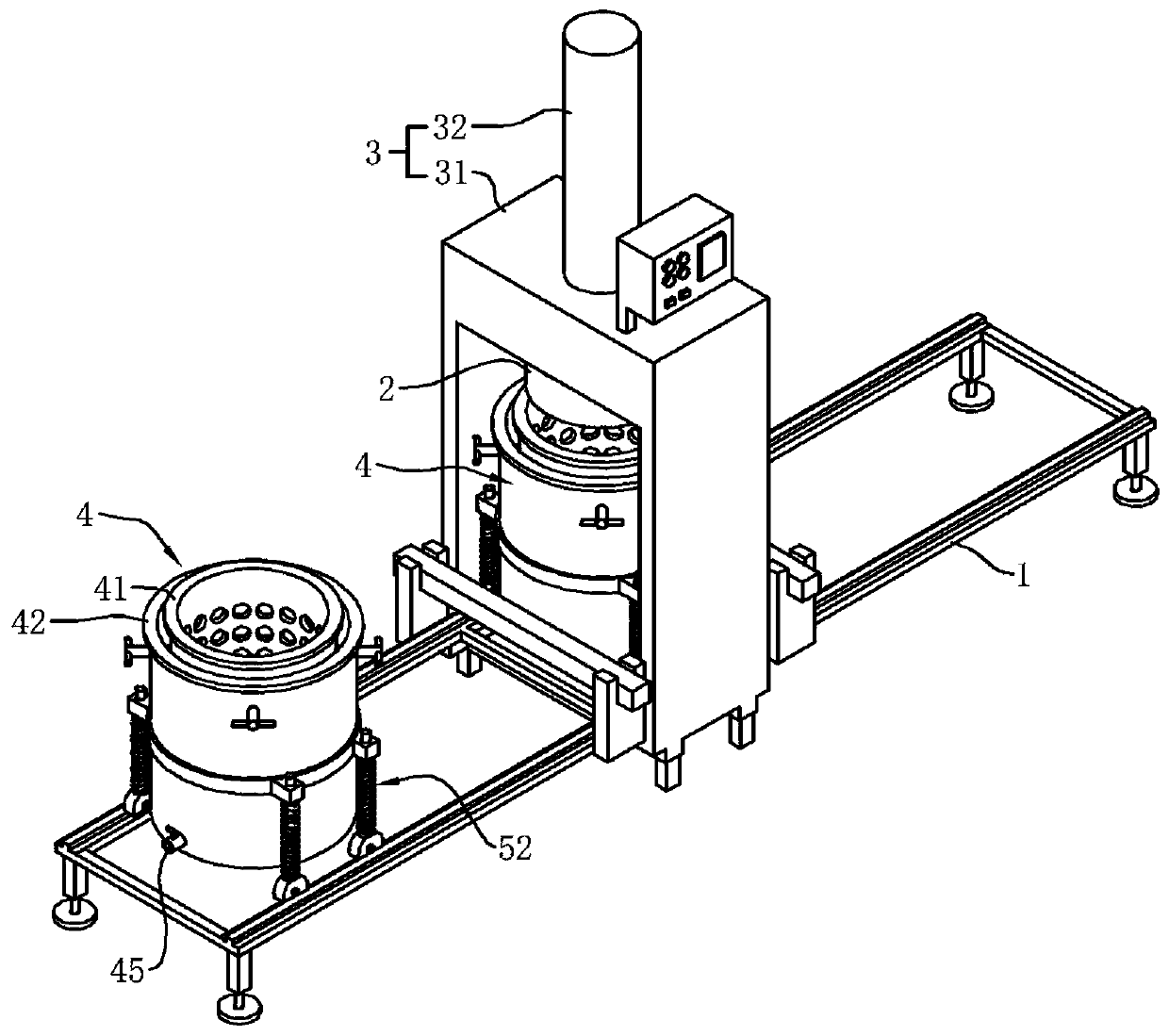

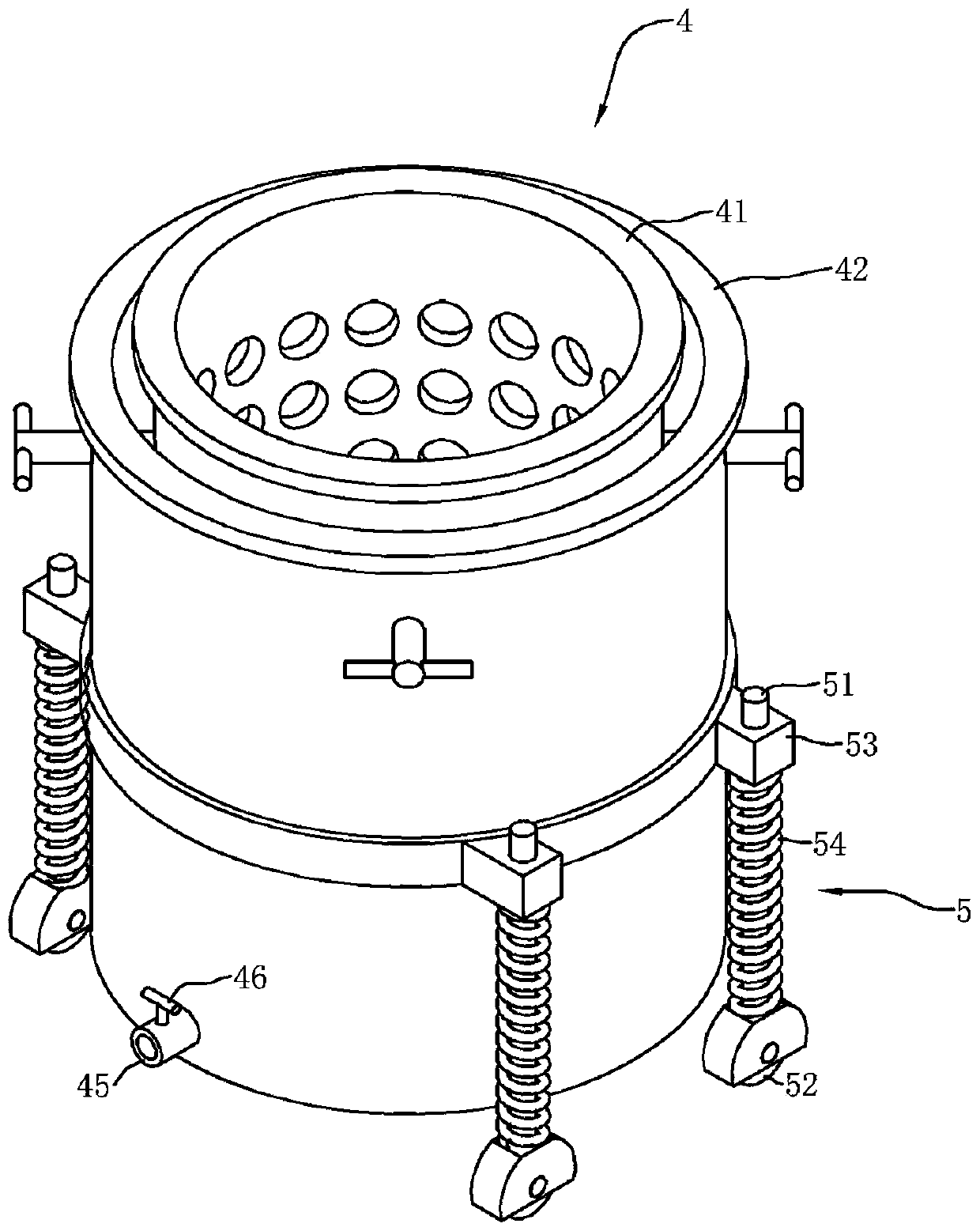

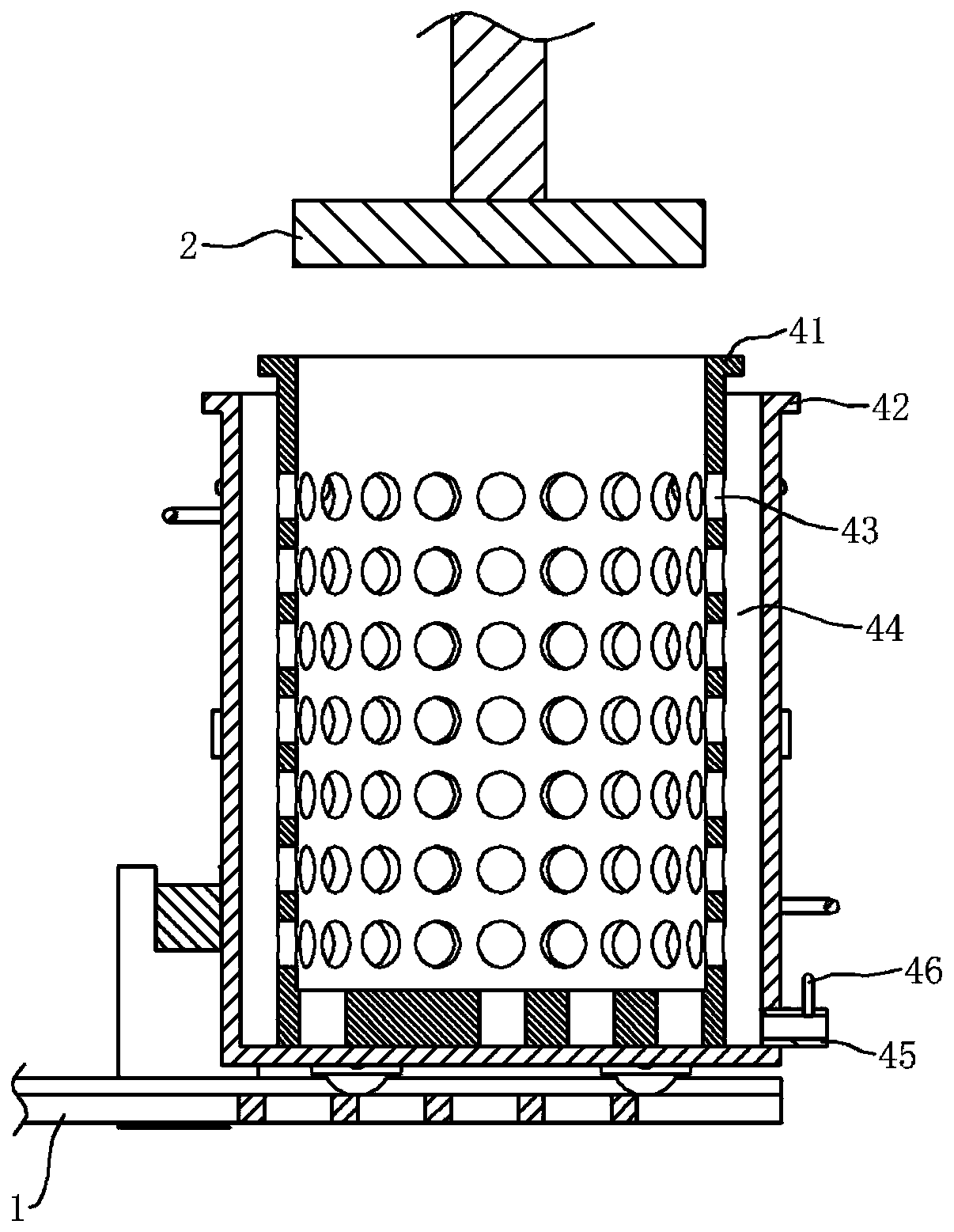

[0045] A double-barrel solid-liquid separator, such as figure 1 As shown, it includes a guide rail 1, a pressing plate 2, an extrusion device 3 and a barrel 4; the extrusion device 3 is located above the guide rail 1, and the barrel 4 is slidably connected with the guide rail 1. After the barrel 4 slides along the guide rail 1, the pressing plate 2 can be connected to the The barrel openings of the material barrel 4 are aligned or staggered along the moving direction of the pressure plate 2; the material barrel 4 has two, the material barrel 4 includes an inner barrel 41 and an outer barrel 42, and the inner barrel 41 is socketed inside the outer barrel 42; figure 2 and image 3 , the wall of the inner barrel 41 is provided with a solid-liquid separation hole 43, and there is a gap 44 between the outer wall of the inner barrel 41 and the inner wall of the outer barrel 42; The internal space of 42 is connected; the discharge pipe 45 is rotatably connected with a valve 46, and...

Embodiment 2

[0060] A separation method such as Figure 7 shown, including the following steps:

[0061] S1: Position initialization, move bucket A and bucket B along the guide rail 1 to the two ends of the guide rail 1 in the direction away from each other;

[0062] S2: Feed material in barrel A, put materials into barrel A;

[0063] S3: barrel A is pressed, barrel B is fed, and barrel A is moved to directly below the pressing plate 2, and the driving device 32 starts to work to drive the pressing plate 2 to squeeze the material in barrel A, and at the same time put the material into barrel B;

[0064] S4: Press barrel B, discharge and feed barrel A, remove the pressed barrel A from the bottom of platen 2 and move to the end of guide rail 1, discharge the slag in barrel A and start feeding, and move barrel B to the Directly below the pressing plate 2, the driving device 32 starts to drive the pressing plate 2 to squeeze the material in the barrel B;

[0065] S5: A barrel is squeezed, B...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com