A kind of mat bamboo chip sorting equipment and its application method

A technology of bamboo pieces and mats, applied in the field of bamboo pieces sorting equipment for mats, can solve problems such as low work efficiency and waste of labor, and achieve the effects of avoiding manual arrangement operations, increasing speed, and efficient sorting efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

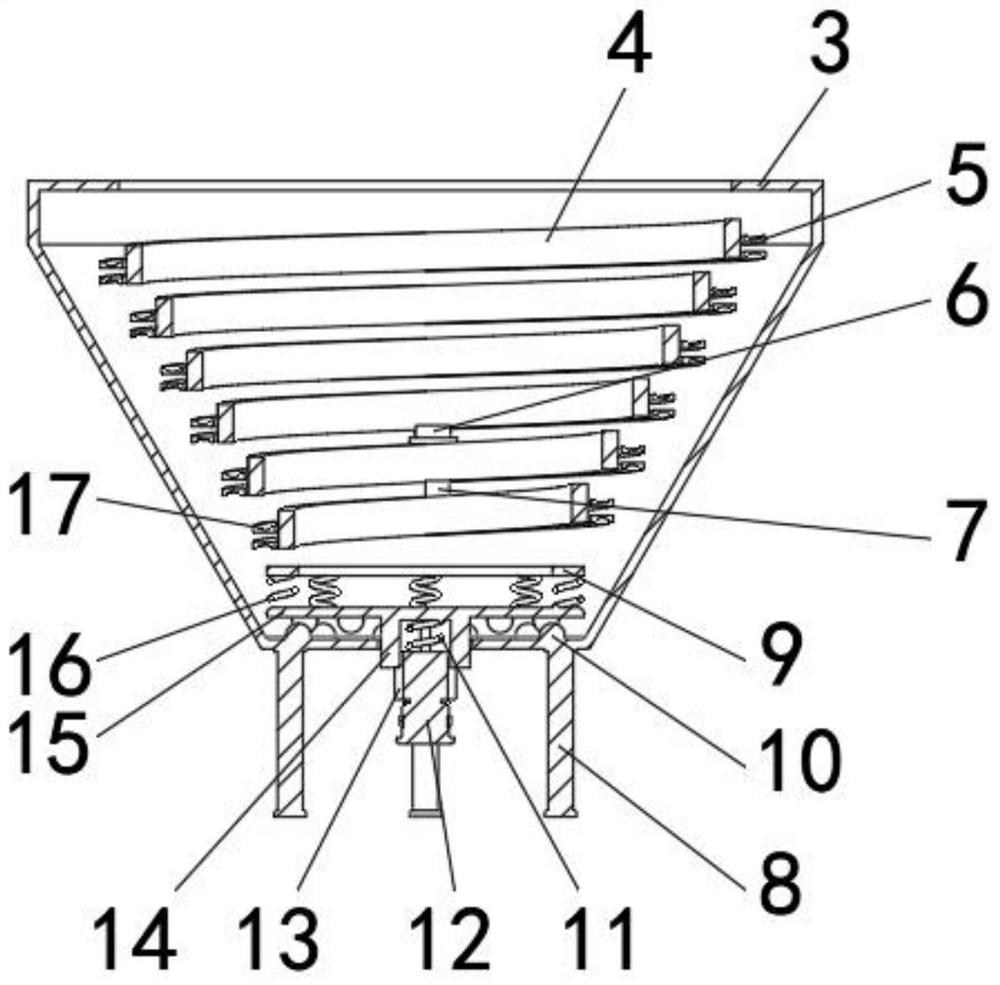

[0029] Embodiment one, with reference to figure 2 and Figure 6-7 , a kind of sorting equipment for mat bamboo slices, comprising a sorting box 3, a turntable 15 is arranged on the inner bottom surface of the sorting box 3, and a hemispherical bump 10 is welded on the inner side of the turntable 15 and the sorting box 3, and the hemispherical There are a plurality of bumps 10, and a plurality of hemispherical bumps 10 are arranged at equal angles around the center of the turntable 15, and the tops of the hemispherical bumps 10 are in a hemispherical structure, and the bottom of the turntable 15 is welded with penetrating points. The rotating sleeve 14 of the sorting box 3, the rotating sleeve 14 and the sorting box 3 are rotatably connected by a bearing sleeve, the bottom of the rotating sleeve 14 is nested with a telescopic sleeve 13, and the top of the telescopic sleeve 13 and the rotating sleeve 14 are passed through the first An extruded spring 11 is elastically connecte...

Embodiment 2

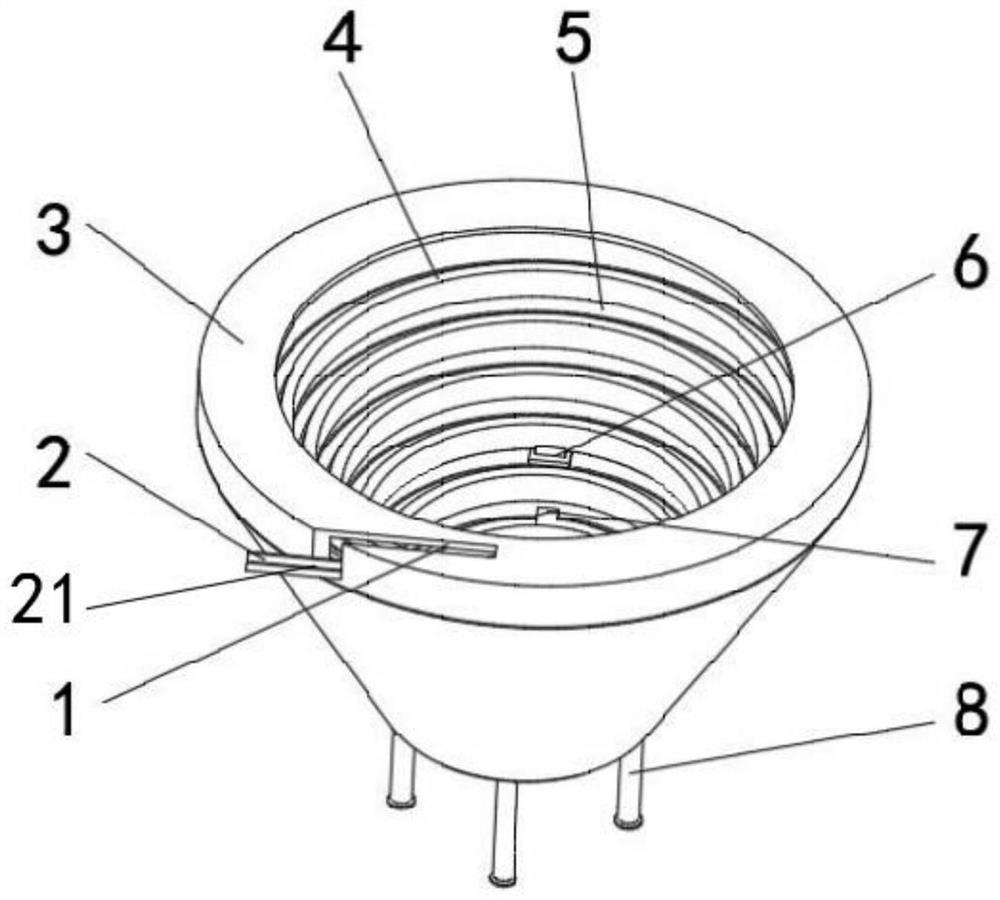

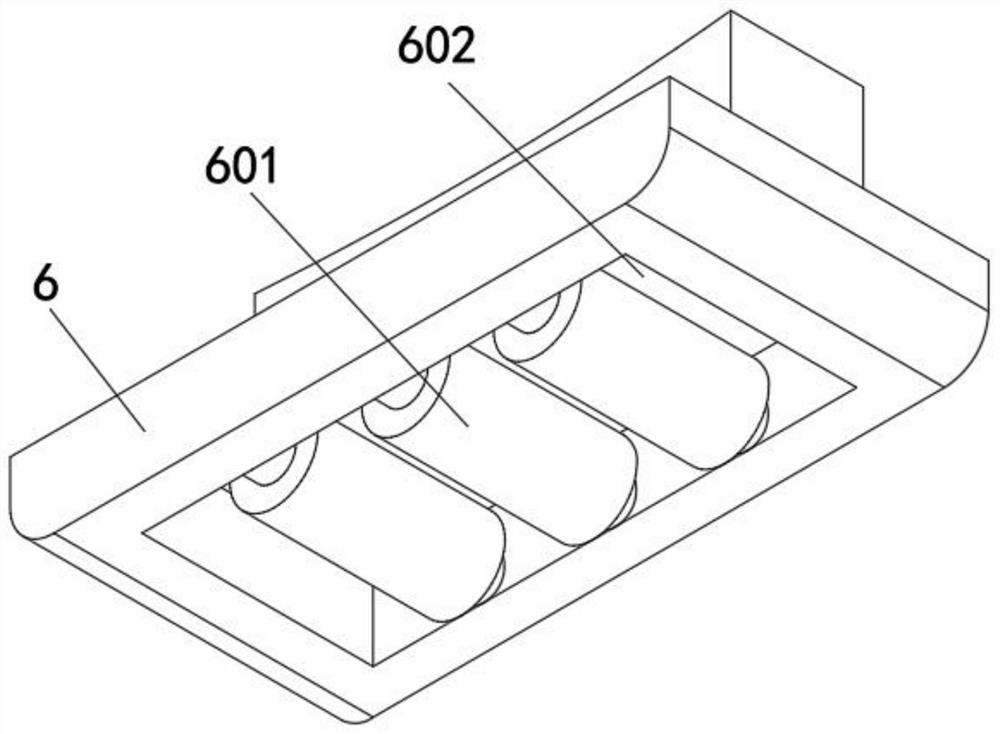

[0030] Embodiment two, refer to Figure 1-6 and Figure 8 , the cross-section of the sorting box 3 is an isosceles trapezoidal structure, and the bottom of the sorting box 3 is welded with a support column 8, and the inner side of the sorting box 3 is welded with a spiral baffle 4, and the connection between the spiral baffle 4 and the sorting box 3 A spiral conveyor belt 5 is arranged between them, and the overall structure of the spiral baffle 4 and the spiral conveyor belt 5 is a spiral structure, and the curvature of the spiral baffle 4 and the spiral conveyor belt 5 is equal, and the height of the top of the spiral baffle 4 is greater than that of the spiral The height of the top of the conveyor belt 5, the inner side of the spiral conveyor belt 5 is rotatably connected with the inner surface wall of the sorting box 3 through the rotating roller 20, and there are a plurality of rotating rollers 20, and the plurality of rotating rollers 20 are all wound around the spiral c...

Embodiment 3

[0031] Embodiment three, refer to figure 2, the top of the turntable 15 is elastically connected to the ring turntable 9 through the second extrusion spring 16, the top of the turntable 9 is attached to the bottom of the screw conveyor belt 5, and the top of the turntable 9 is provided with anti-slip particles, and the turntable 9 passes through the turntable 15 to rotate, and the rotation of the ring-shaped turntable 9 will drive the screw conveyor belt 5 to rotate through the anti-skid particles, and the screw conveyor belt 5 will limit the rotation position through a plurality of rotating rollers 20 during the rotation process, so that the screw conveyor The belt 5 will be able to be conveyed in a helical manner.

[0032] Working principle: First, place the bamboo slices inside the sorting box 3, the bamboo slices will be attached to the top of the turntable 15 under the action of gravity, then start the drive motor 12, the drive motor 12 will drive the telescopic sleeve 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com