Turret leveling device for special vehicle for high-altitude operations

A technology for high-altitude operation and leveling device, applied in cranes and other directions, can solve the problems of complex device, poor carrying capacity and low precision of the adjustment device, and achieve the effects of low cost, strong carrying capacity and high adjustment accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

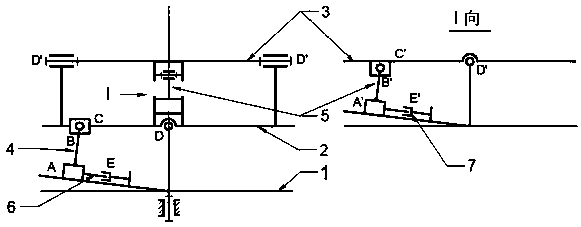

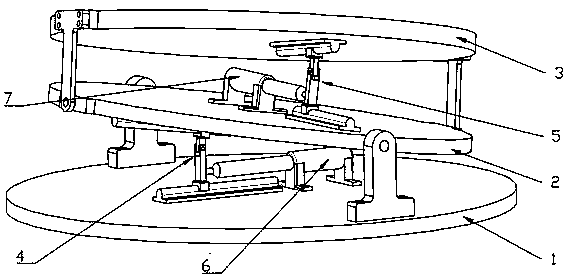

[0026] A special vehicle turret leveling device for aerial work, figure 1 Its structural principle diagram, figure 2 A schematic diagram of its structure. The turret leveling device is installed on the frame turret 1 and consists of a lower plate 2 with a rotating shaft D, an upper plate 3 with a rotating shaft D' and its rotating actuators stacked up and down. Wherein, the rotation axis D' of the upper plate 3 is parallel to the top surface of the lower plate 2, the rotation axis D of the lower plate 2 is parallel to the top surface of the frame turret 1, and the rotation axis D of the lower plate 2 is parallel to the rotation axis D' of the upper plate 3. It is arranged at a vertical staggered angle; the rotating actuator 4 of the lower plate 2 around the rotating axis D is a double-slider four-bar mechanism ABCD, and the rotating actuator 5 of the upper plate 3 around the rotating axis D' is a double-slider four-bar mechanism A'B'C 'D', the sliders at A and A' are active...

Embodiment 2

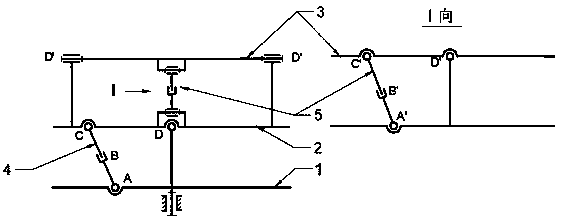

[0029] The structural schematic diagram of the turret leveling device using the swing cylinder four-bar mechanism is as follows image 3 shown, is figure 1 and figure 2 The leveling device shown is a simplified construction. image 3 The rotary actuators 4 and 5 shown are swing cylinder four-bar mechanisms, which are replaced by swing cylinders ABC and A'B'C' respectively figure 1 and figure 2 The dual slider widget in . Since the swing cylinder is the original moving component and is a linear actuator, it can be realized directly by using a hydraulic cylinder, a linear motor or a lead screw and nut pair according to the conditions of the power source. The leveling device adopting the swing cylinder four-bar mechanism has simpler structure and lower cost.

Embodiment 3

[0031] figure 1 In addition to hydraulic cylinders, other types of linear actuators such as air cylinders, linear motors, screw nut pairs, etc. can also be used for the driving elements 6 and 7 shown in , depending on the application conditions.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com