Preparation method for low-cost plastic suction sheet used for electronic packaging

A manufacturing method and packaging technology, which is applied in the field of low-cost electronic packaging blister sheet manufacturing, can solve the problems of rising product costs, high prices, and shedding, and achieve the effects of cost reduction, effect maintenance, and surface particle problems

Inactive Publication Date: 2019-06-11

KUNSHAN HENGGUANG PLASTIC PROD

View PDF3 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

In this method, when the mixture is melted by the host screw, the screw temperature needs to be increased to the melting peak of HIPS, otherwise the filling masterbatch will leave fine particles on the surface of the product due to insufficient melting, and these particles will be damaged by packaging electronic materials after blister molding. It will fall off due to the friction and vibration generated when it falls off, and will be adsorbed on the surface of electronic products after falling off; moreover, the price of HIPS is relatively expensive, which will lead to an increase in product cost

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1~5

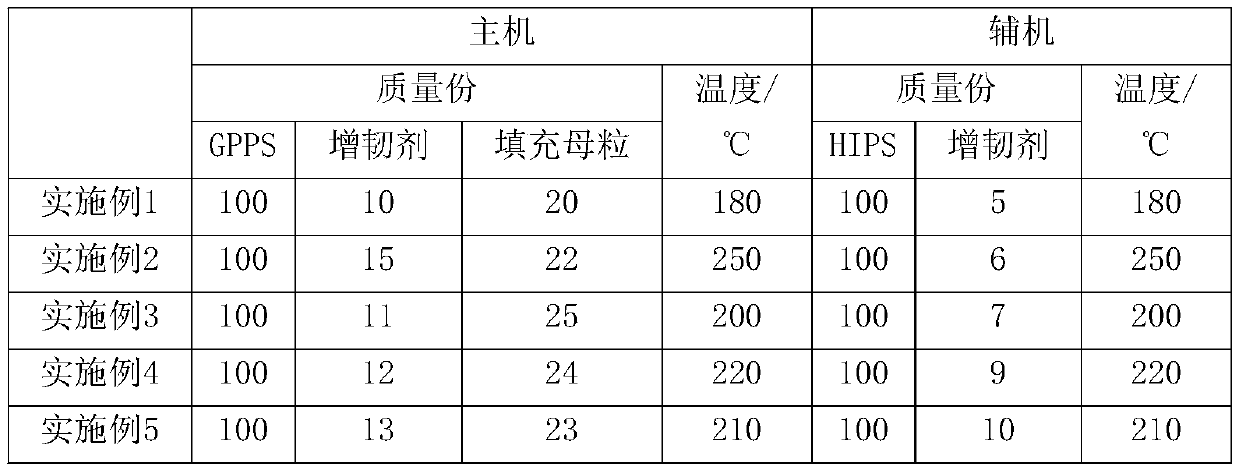

[0023] Prepare the sheet according to the raw material ratio and conditions shown in Table 1:

[0024] Table 1:

[0025]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention belongs to the technical field of high-molecular packaging materials, and in particular relates to a preparation method for a low-cost plastic suction sheet used for electronic packaging. The method comprises the following steps: adding 10-15 wt% of a toughening agent and 20-25 wt% of a filler masterbatch into general purpose polystyrene (GPPS) particles, performing mixing to form amain ingredient, adding 5-10 wt% of a toughening agent into high impact polystyrene (HIPS) particles, performing uniformly mixing to obtain an auxiliary ingredient, performing melting on the auxiliaryingredient, allowing the molten auxiliary ingredient to pass through an extruder distributor to be divided into two outer layers, covering two surfaces of a middle layer to form a three-layer continuous sheet, and performing cooling solidification on the sheet by using cooling water. According to the formulation of the plastic suction sheet provided by the invention, the sheet GPPS is used to replace a portion of the HIPS, so that the costs are reduced, the effects are maintained, and the problem of surface layer particles is avoided.

Description

technical field [0001] The invention relates to the technical field of polymer packaging materials, in particular to a method for manufacturing a low-cost electronic packaging blister sheet. Background technique [0002] Commonly used materials for blister sheets include PS / PET / PP / ABS, etc., which have a wide range of applications, such as hardware, electronics, food and medical packaging. HIPS (high impact polystyrene, high impact polystyrene) is often used in blister sheets for electronic packaging. Its manufacturing principle is to use HIPS as the main material, add toughening agent in turn, fill masterbatch, and then extrude. In this method, when the mixture is melted by the host screw, the screw temperature needs to be increased to the melting peak of HIPS, otherwise the filling masterbatch will leave fine particles on the surface of the product due to insufficient melting, and these particles will be damaged by packaging electronic materials after blister molding. Th...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C08L25/06C08L51/04

Inventor 刘磊

Owner KUNSHAN HENGGUANG PLASTIC PROD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com