Low-weight LED heat dissipating device and portable UVLED curing equipment

A heat dissipation device and curing equipment technology, applied in lighting and heating equipment, cooling/heating devices of lighting devices, lighting devices, etc., can solve the problems of reducing the convenience of installation and carrying, potential safety hazards, increasing costs, etc., and achieve improvement The Effect of Availability and Utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

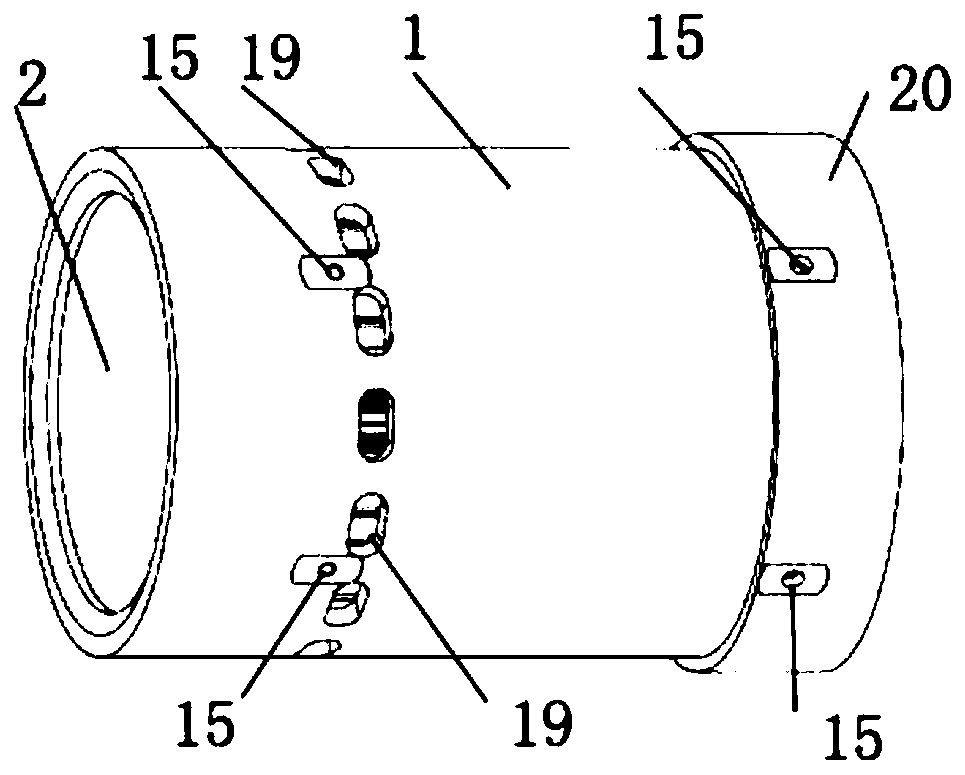

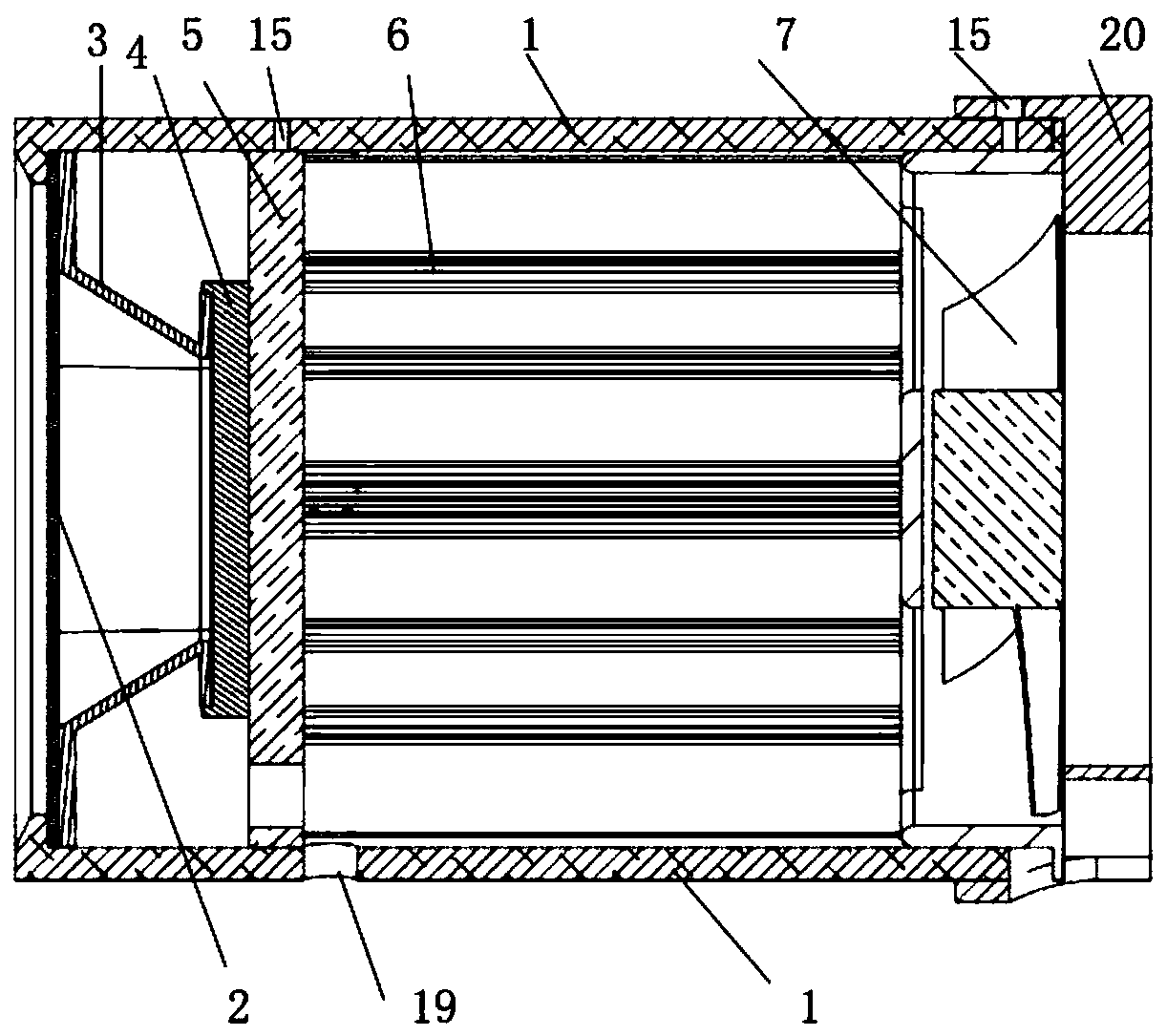

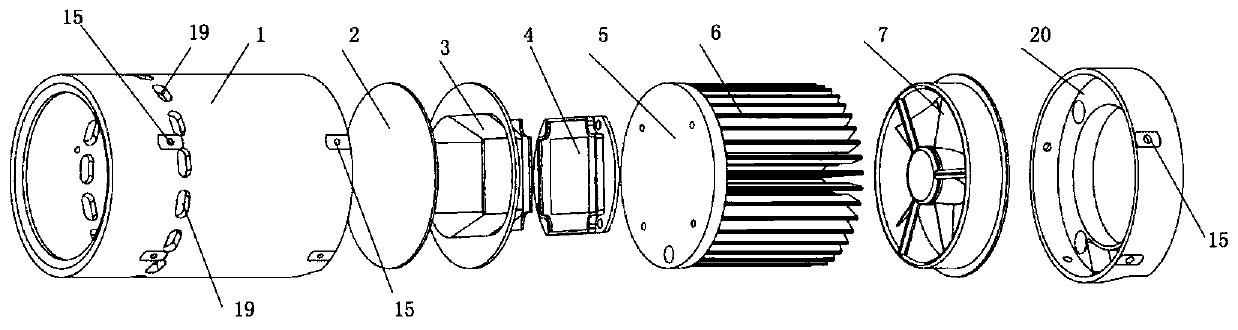

[0039] A light-weight LED heat dissipation device, the heat dissipation device includes an outer cylinder 1, and the interior of the outer cylinder 1 is sequentially installed with a protective window 2, a reflector 3, an LED light source 4, a heat dissipation bottom plate 5, and a heat dissipation fin 6 from front to back and fan 7; the LED light source 4 is fixed on the front end surface of the heat dissipation bottom plate 5; the outer edge of the heat dissipation bottom plate 5 is in contact with the inner wall of the outer cylinder 1; a plurality of heat dissipation holes 19 are opened on the outer cylinder 1, and the heat dissipation The hole 19 is located at the connection position between the heat dissipation fin 6 and the heat dissipation bottom plate 5 . A plurality of cooling holes 19 form a ring around the outer cylinder 1 .

[0040] The front edge of the heat dissipation hole 19 is on the same plane as the heat dissipation bottom plate 5 .

[0041] The heat dissi...

Embodiment 2

[0055] A portable UVLED curing device, the curing device includes a heat sink 30, a handle 9 and a battery assembly 10; The heat dissipation device is the heat dissipation device described in Embodiment 1.

[0056] The connecting part 20 (tubular connector) is fixedly connected to the outer cylinder 1 and the handle 9 by screws, and the battery assembly 10 is clamped on the handle 9 through a connector;

[0057] A power converter 11 and a switch 12 are installed inside the handle 9 (in an L shape), and the fan 7 can be fixed on the outer cylinder 1 by screws (the connection method in Embodiment 1); it can also be glued and fixed on the handle 9 close to the outer cylinder 1 (can be used as an alternative); the handle 9 shell assembly is provided with a plurality of handle cooling holes 18 for ventilation and heat dissipation.

[0058] The handle 9 shell assembly is divided into left and right two pieces, fixed by screws. The cooling fan 7, the power converter 11, the control...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com