Supporting plate-free static brick machine and brick collecting device

A technology of static pressure and brick making machine, which is applied to supply devices, unloading devices, ceramic molding machines, etc., can solve problems such as inconvenience in use, and achieve the effects of simplified structure, inconvenient use and reasonable structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

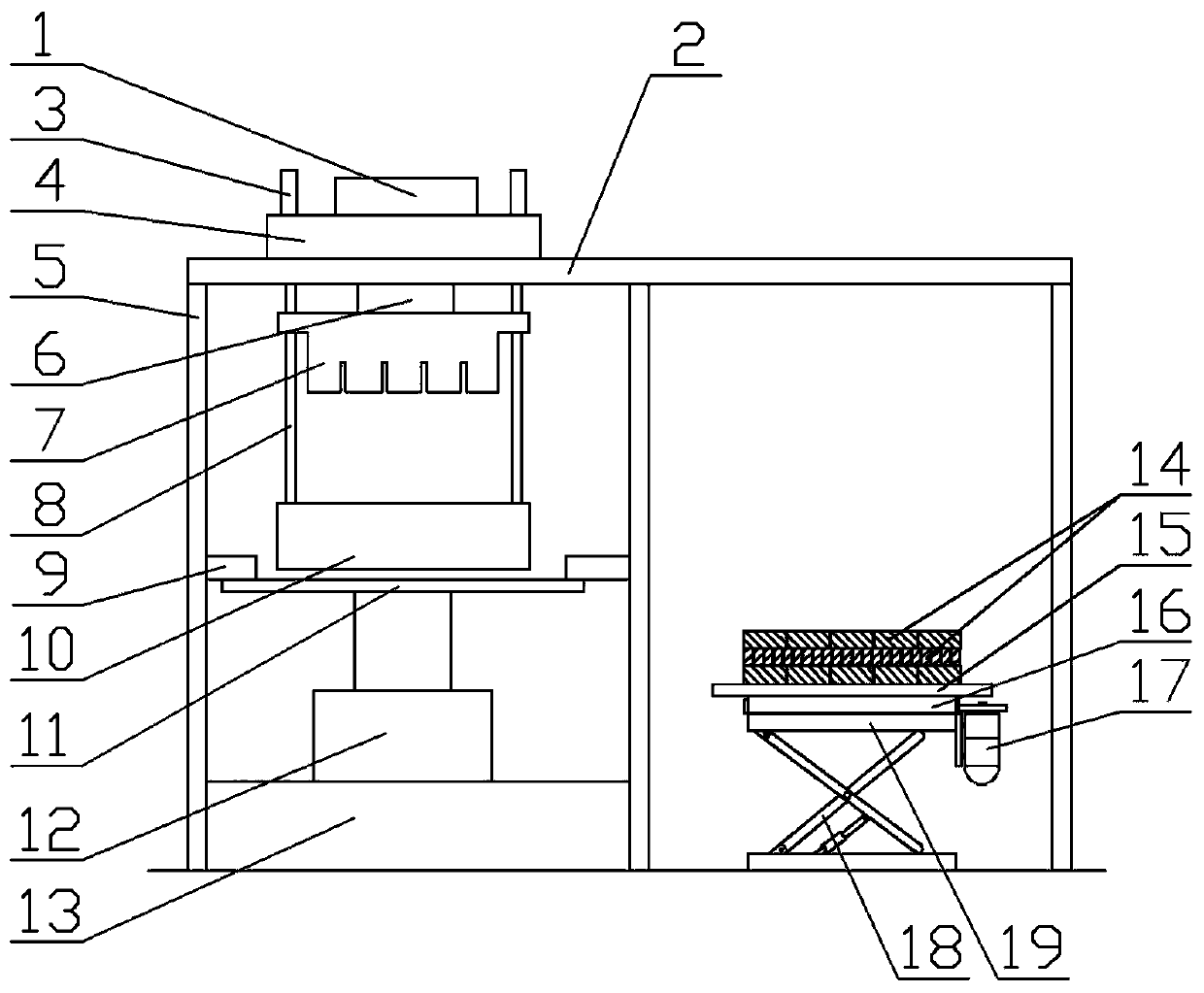

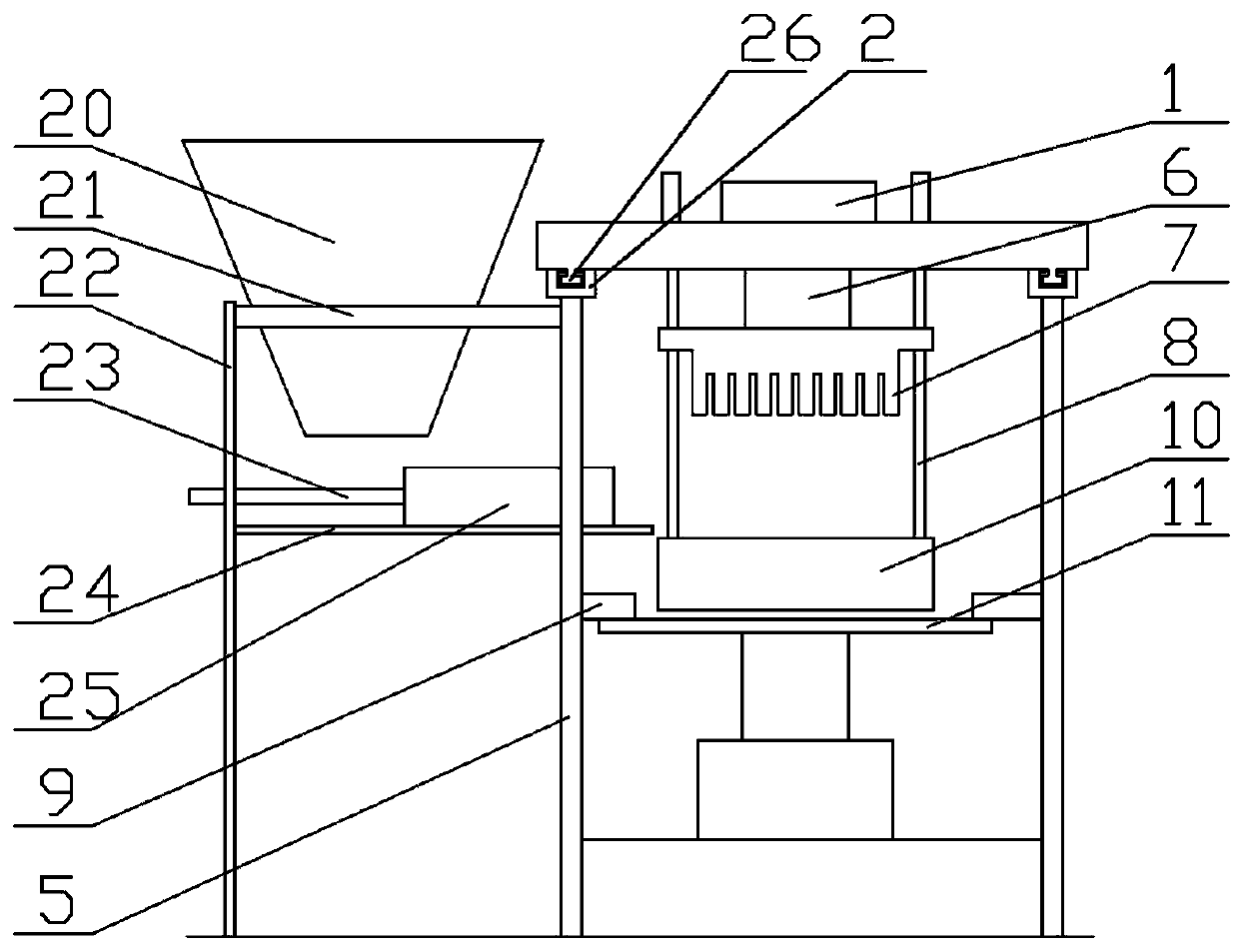

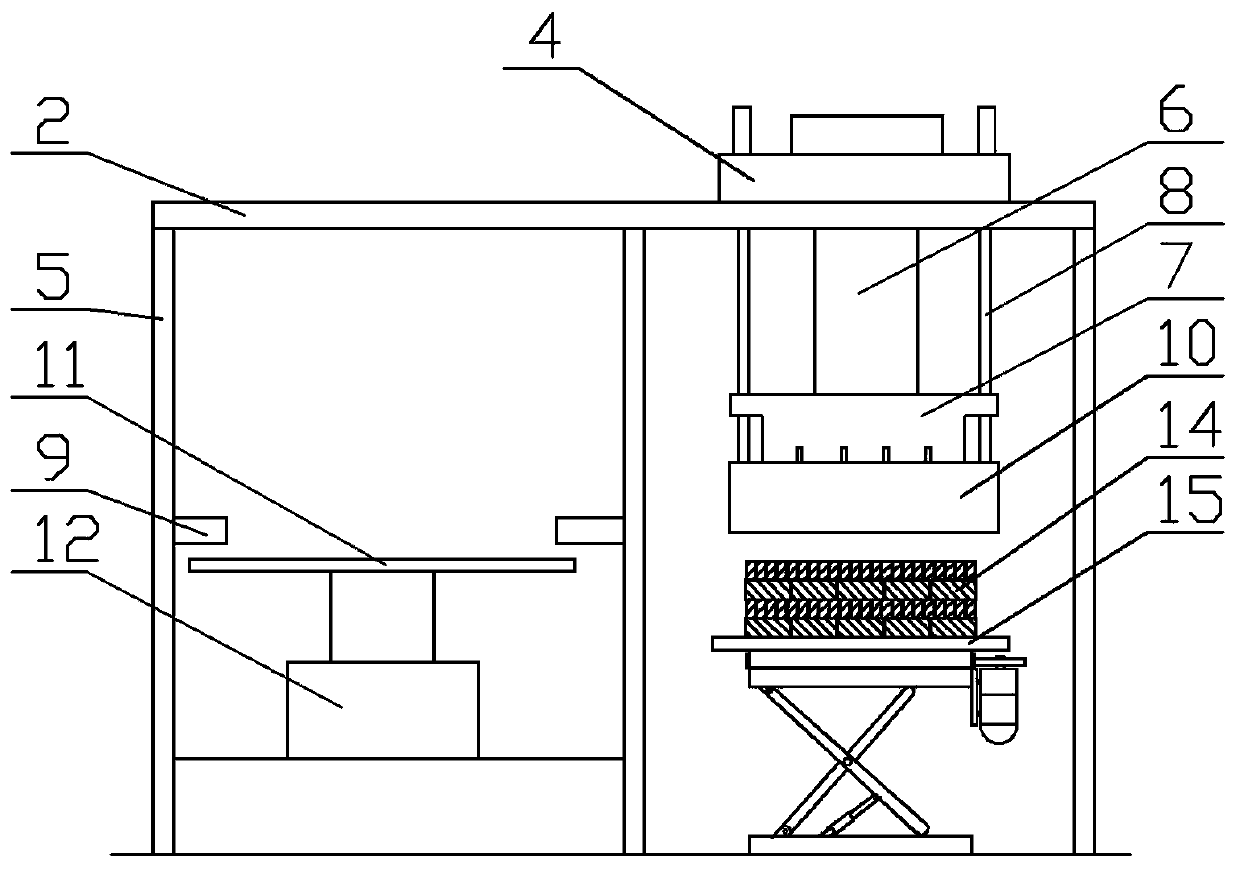

[0019] Embodiment 1: According to Figure 1-Figure 3 , a pallet-free static brick machine and a brick receiving device, it includes a main frame 5; a side of the main frame 5 is provided with a mold pressure head 7 and a mold cover 10; the top of the main frame is provided with a beam 2 The beam 2 is provided with a support platform 4 for sliding connection; the middle of the support platform 4 is provided with a pressing oil top 1; the pressing oil top 1 is connected with the mold head 7 through a guide post 6; the supporting platform The four corners of 4 are provided with a demoulding oil top 3; the demoulding oil top is connected with the mold cover 10 through a pull rod 8; a crimping platform 11 is provided below the mold cover 10; There is a lifting oil top 12 and a support 13 .

[0020] The other side of the main frame 5 is provided with a supporting plate 19; the lower part of the supporting plate is provided with a lifting frame 18, and a turntable 16 is arranged abo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com