Crane track detection trolley

A track detection and crane technology, applied in the track system, measuring device, traveling mechanism, etc., can solve the problems of high purchase and maintenance costs, inability to detect on-line in real time, unstable operation, etc., and achieve simple structure, low production cost, and applicable wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

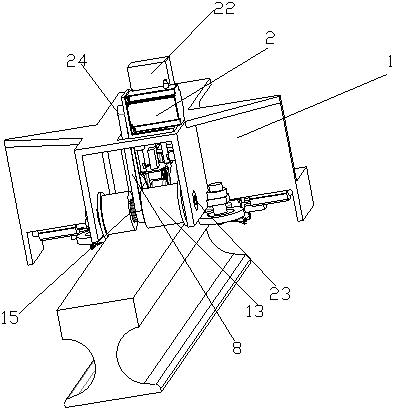

[0027] now combined with Figure 1-6 The invention of the detection trolley is further described in detail.

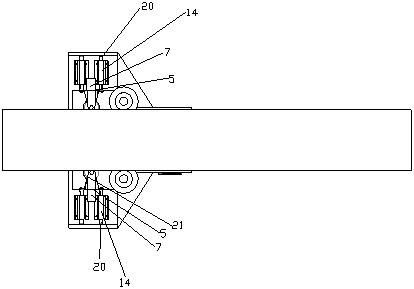

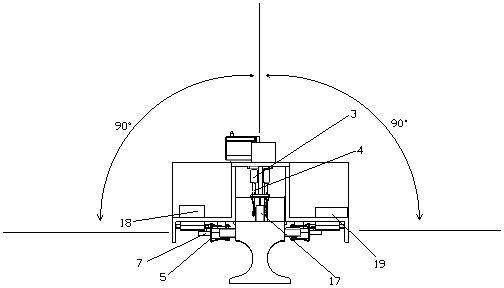

[0028] Such as figure 1 As shown, a crane track detection trolley, the detection trolley consists of five parts: frame 1, driving device, sliding device, detection device, anti-overturning device. The driving device is fixed on the top of the vehicle frame 1, and the sliding devices are respectively fixed on the inside of the vehicle frame 1 directly below and behind and close to the left and right sides of the track, and the left and right angles of the rollers 6 are detected by the upper surface of the track at 90° The detection rollers 6 on both sides are arranged in the direction and the detection rollers 6 on both sides are respectively offset on both sides of the track. The detection devices are respectively placed on the top of the fixed steel plate 5 directly above the three sliding devices, and the anti-overturning device is fixed on the frame. The position ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com