Adjustable pin shaft installation platform

An installation platform and adjustable technology, applied in the direction of lifting devices, etc., can solve the problems of complicated construction process, high cost, surface damage of pins, etc., and achieve the effect of convenient positioning and movement, accurate positioning, and low safety risk.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The following examples can enable those skilled in the art to understand the present invention more comprehensively, but the present invention is not limited to the scope of the described examples.

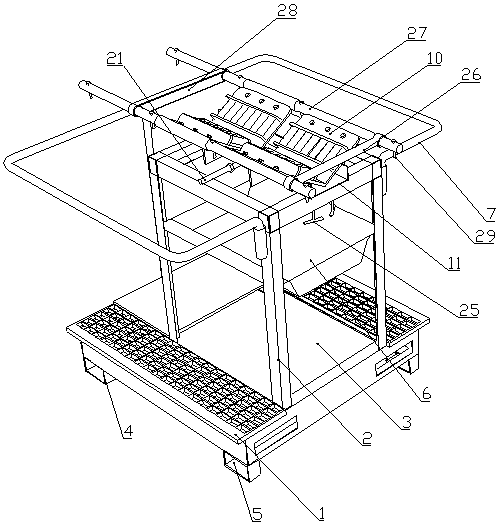

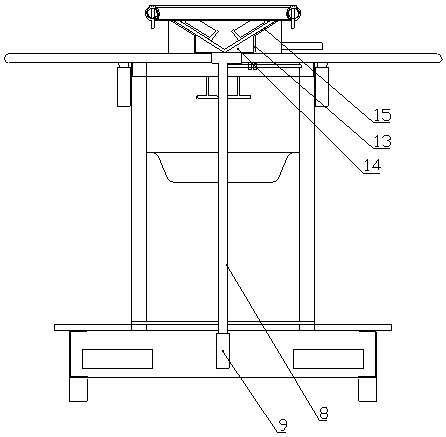

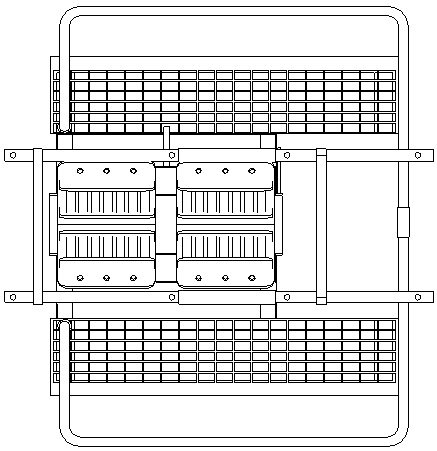

[0039] Such as Figure 1-Figure 9 An adjustable pin-mounted platform is shown, including

[0040] A working base, the working base includes a standing platform 1 and a mounting bracket 2 arranged on the standing platform, the standing platform 1 is a cuboid structure, and the two sides of the upper end surface of the standing platform 1 are fence structures for operators to stand on, The mounting bracket 2 is a rectangular parallelepiped frame structure fixed on the standing platform 1, and a through groove 3 is provided on the standing platform 1 directly below the mounting bracket 2 simultaneously.

[0041] A forklift positioning seat 4 is arranged at four corners of the bottom end of the stand platform 1, and a through hole 5 for inserting a forklift arm is arranged in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com