Multiphase hydrogen storage alloy with high hydrogen desorption efficiency and its preparation method and application

A high-efficiency technology for hydrogen storage alloys, applied in the field of hydrogen storage alloys, can solve the problems of low effective hydrogen desorption rate, and achieve the effects of simple production methods, easy activation, and high hydrogen storage capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Embodiment 1 proposes a multi-phase hydrogen storage alloy with high hydrogen release efficiency, and the hydrogen storage alloy is divided according to A:V 53 Ti 8 Cr 27 Fe 12 , B: Ti 28.00 V 22 Fe 31 Cr 19 , C:V 5.05 Ti 94.95 40g of the determined weight percentages of the alloy formula were weighed, and the metal elemental raw materials used in the experiment were all above 99.9%, and then smelted in a non-consumable vacuum electric arc furnace under an argon protective atmosphere. In order to ensure uniform composition, the alloy ingot was turned over and smelted 4 times, and then cooled to room temperature with the furnace. After the outer surface of the ingot is polished and polished, mechanically pulverize and sieve through 200 meshes, respectively weigh 18.50g of A alloy powder, 0.85g of B alloy powder, and 0.65g of C alloy powder. After mixing, mechanical ball mill for 2 hours, weigh and mix 2g of multi-phase hydrogen storage alloy powder was put into ...

Embodiment 2

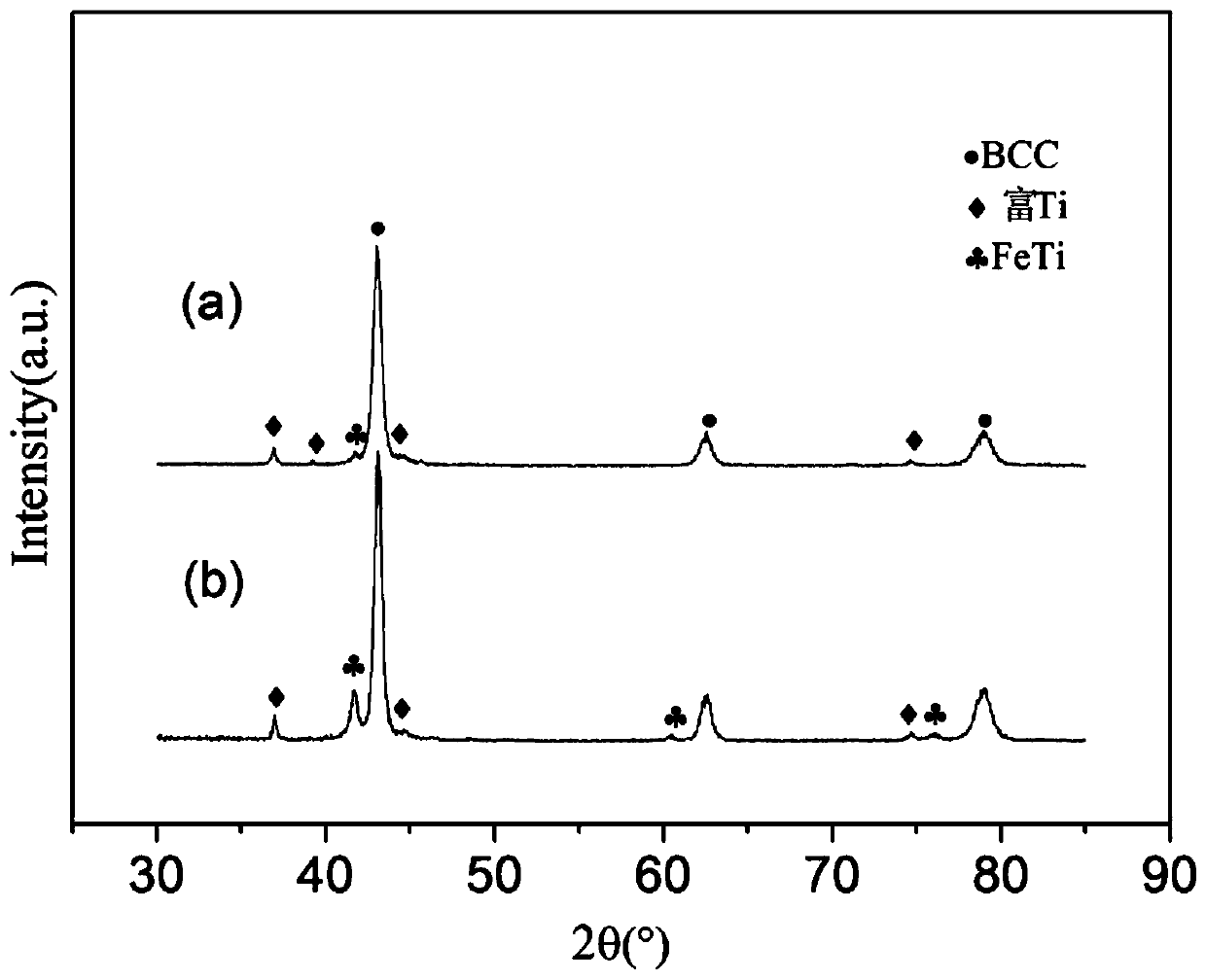

[0032] The preparation method etc. are all the same as in Example 1, but the alloy proportion is different from that in Example 1, and the chemical formula of the alloy in Example 2 is according to A: V 51 Ti 9 Cr 28 Fe 12 , B: Ti 35 V 15 Fe 30 Cr 20 , C:V 2.77 Ti 97.23 The alloy formula is determined, respectively weighing 18.9g of A alloy powder, 0.16g of B alloy powder, and 0.94g of C alloy powder, and the PCT test data are listed in Table 1 below. The XRD diffraction pattern of the hydrogen storage alloy of embodiment 1-2 is as figure 1 shown.

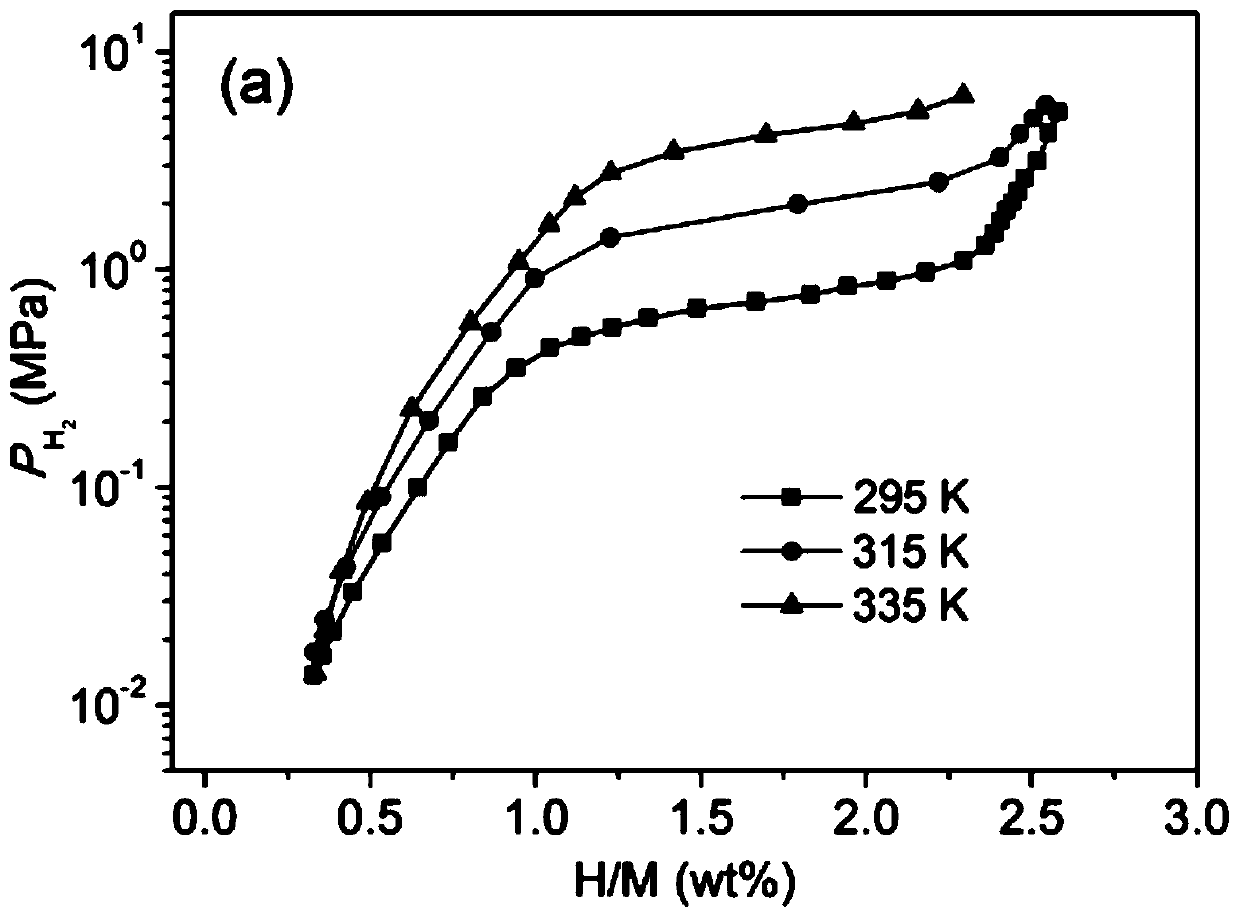

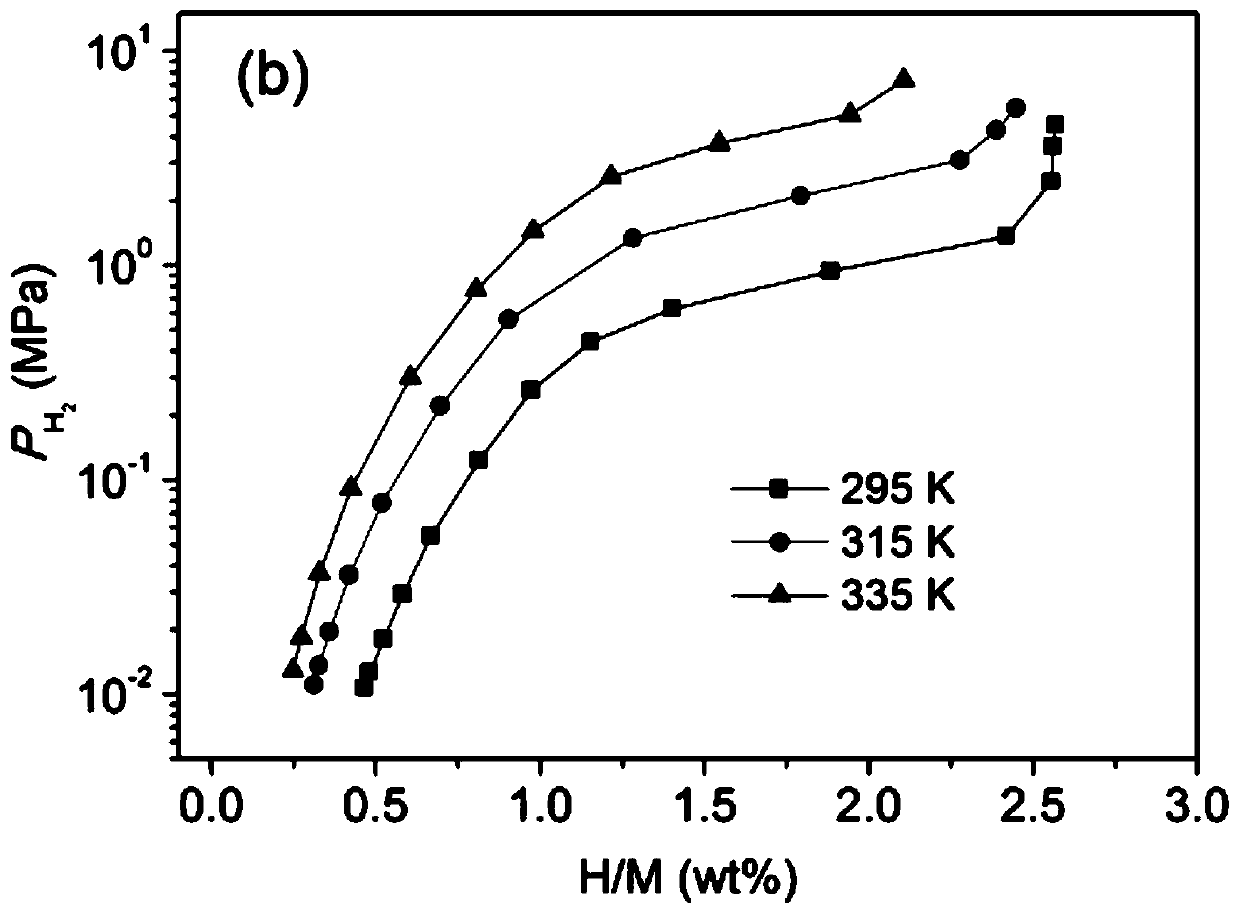

[0033] Table 1 Alloy hydrogen storage properties

[0034]

[0035] C tot - saturated hydrogen absorption capacity (wt.%); C des —Hydrogen release amount (wt.%); S f is the tilt factor of the hydrogen release platform; P eq is the hydrogen release platform pressure (MPa); R is the hydrogen release rate (R=(C des / C tot )×100%).

[0036] The results of the data in Table 1 show that the hydrogen release efficiency ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com