Large automatic wall-plastering machine

A wall plastering machine, a large-scale technology, applied in the direction of buildings, building structures, etc., to facilitate entry and exit of buildings, ensure the verticality of the fuselage, and ensure the effect of fixing the fuselage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

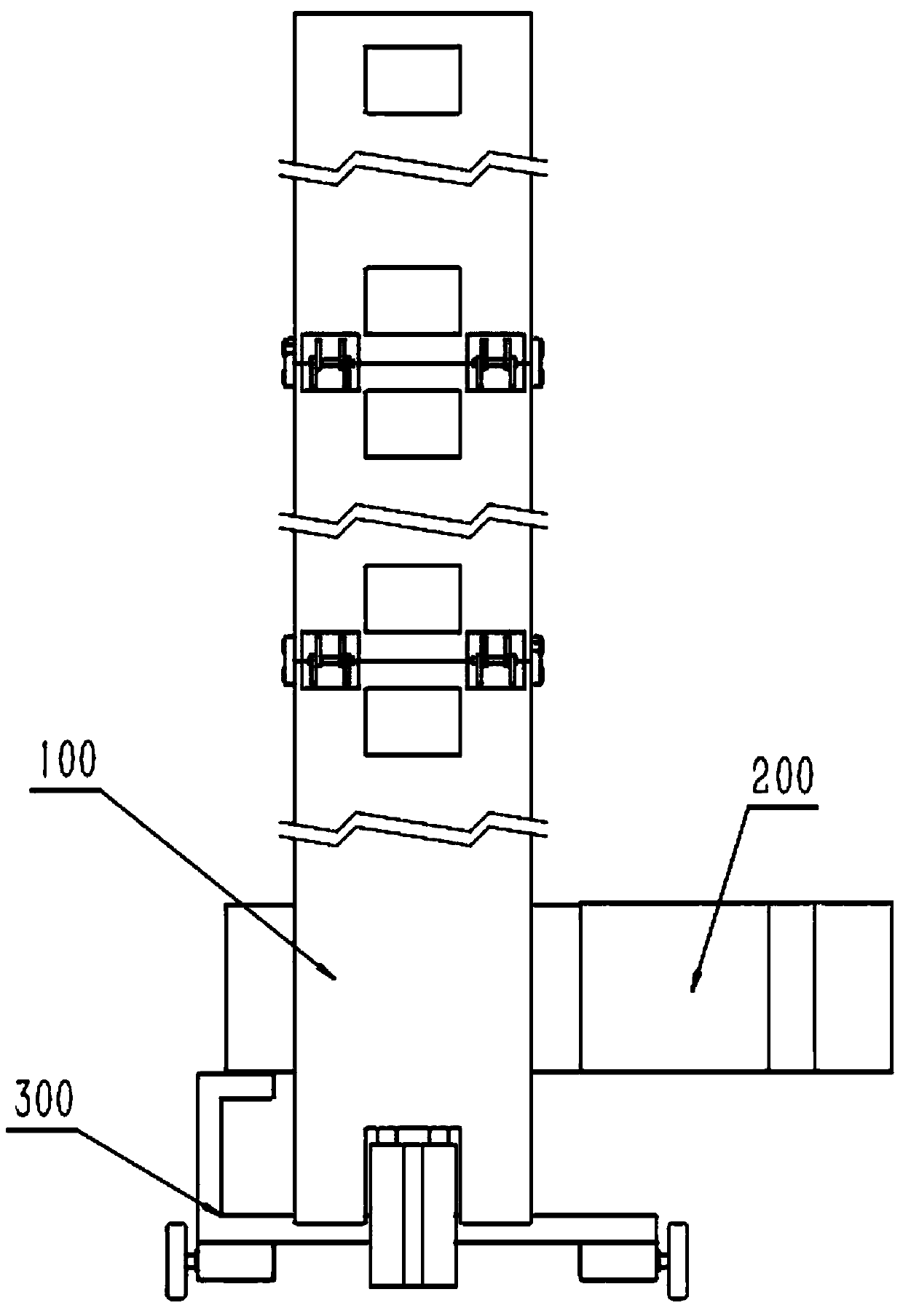

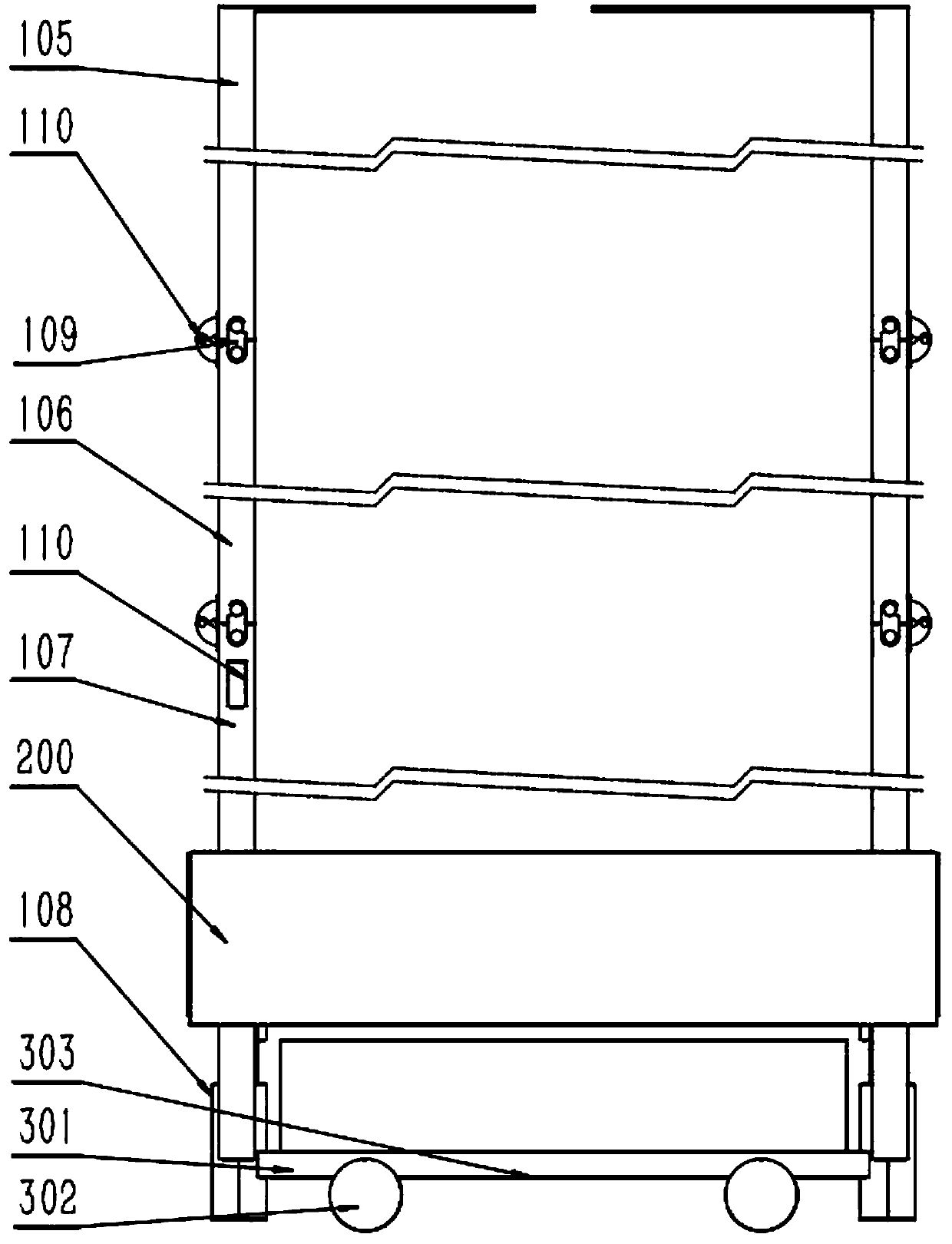

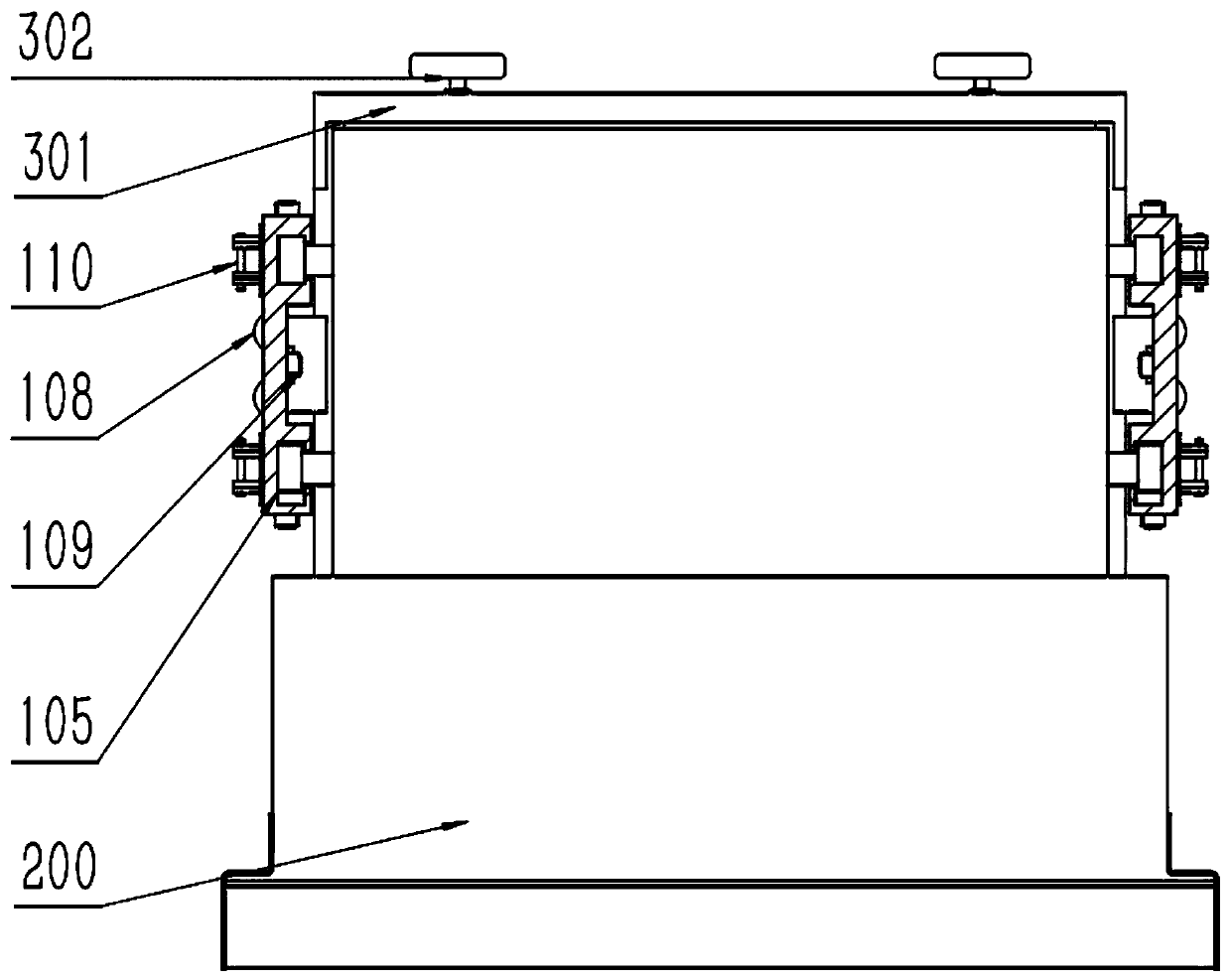

[0035] The invention discloses a large-scale automatic wall plastering machine. The invention is further described through the accompanying drawings and embodiments.

[0036] This machine is made up of transmission lifting device 100 , material conveying device 200 and chassis walking device 300 . The transmission lifting device 100 includes a motor 101, a shaft coupling 102, a worm gear reducer 103, a gear 104, an upper stand 105 with a rack, a neutral stand 106 with a rack, a lower stand 107 with a rack, and a supporting hydraulic cylinder 108. Connect the hook 109, the verticality sensor 110, the pin shaft 111 and the like. The material feeding and plastering device 200 includes a hopper 201, a screw mechanism 202 with a feeding pipeline, a conveyor belt 203, an upper adjustment hydraulic cylinder 204, a lower adjustment hydraulic cylinder 205, an adjustment connector 206, a wall plastering board 207, and an ash retaining plate 208 and vibration motor 209 etc. The chassis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com