Isolation swirl control globe valve

A technology of eddy current control and cut-off tubes, which is applied in the direction of diaphragm valves, diaphragms, valve devices, etc., can solve problems such as liquid leakage, and achieve the effects of reducing loss, preventing leakage, and suppressing leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

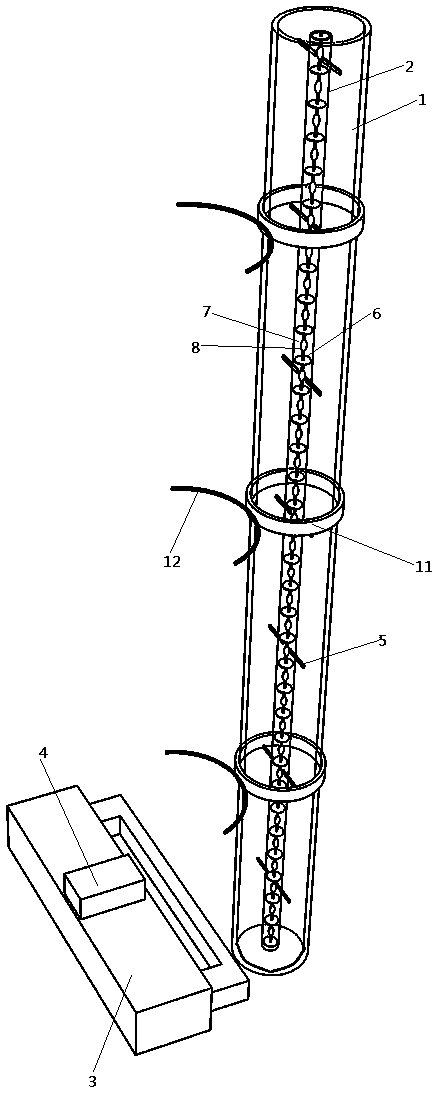

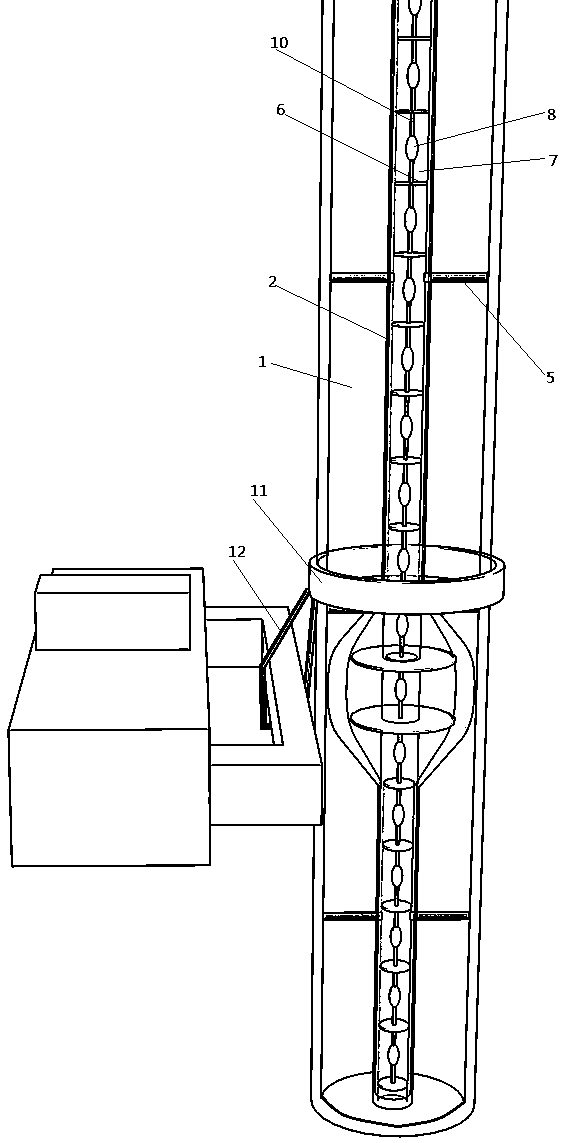

[0021] The present invention will be described in further detail below with reference to the accompanying drawings and specific embodiments.

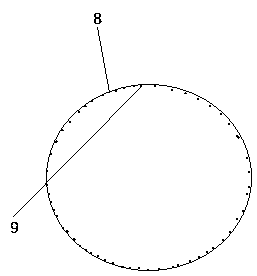

[0022] like Figure 1-3 As shown in the figure, the isolation eddy current control type globe valve includes a main pipeline 1, an elastic inner core tube 2, an eddy current heater 3, and a temperature controller 4; the inner surface of the main pipeline 1 and the outer surface of the elastic inner core tube 2 are evenly and fixedly connected There are several restriction ropes 5; the restriction ropes 5 are all coated with waterproof paint; the inner surface of the elastic inner core tube 2 is evenly fixed and connected with several elastic partition boards 6 in the up and down direction; An expansion cavity 7 is formed between the expansion cavity 7; an elastic ball 8 with a cavity inside is placed in the expansion cavity 7; the inner surface of the elastic ball 8 is pasted with metal powder 9; the interior of the elastic ball 8 is fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com