A method for manufacturing execution management control

A technology of management control and manufacturing execution, applied in the direction of manufacturing computing systems, data processing applications, collaborative operation devices, etc., can solve problems such as reduced efficiency, inability to know in time in the background, losses, etc., to improve efficiency and accuracy, and optimize production Effects of the planning and production execution process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

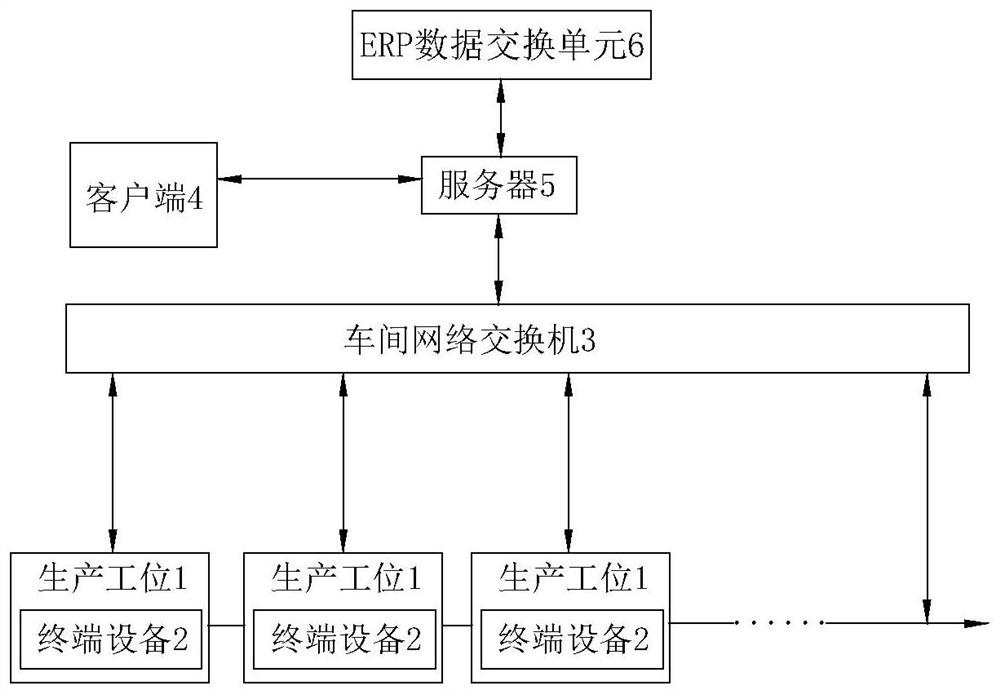

[0044] This embodiment discloses a method for manufacturing execution management control, which is executed based on the system for manufacturing execution management control. This system adopts the S+BS architecture, and the database can use MSSQL or MySQL. The program module has a clear structure and can be used according to Features need to be configured. Specifically, such as figure 1 As shown, the system includes an ERP data exchange unit 6, a background management system, a server 5, a local area network / workshop intranet and a plurality of terminal devices 2, and each production station 1 of the assembly line corresponds to a terminal device 2, and the terminal device 2 It can be connected to the local area network through the workshop network switch 3, and the background management system can be connected to the local area network through the wireless network, so that each system of production execution can run on a unified shared and centralized network platform.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com