An intelligent factory management and control model and a management and control method thereof

A model and factory technology, applied in the field of intelligent factory control based on parallel systems and micro-service frameworks, to achieve the effect of improving reusability and scalability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

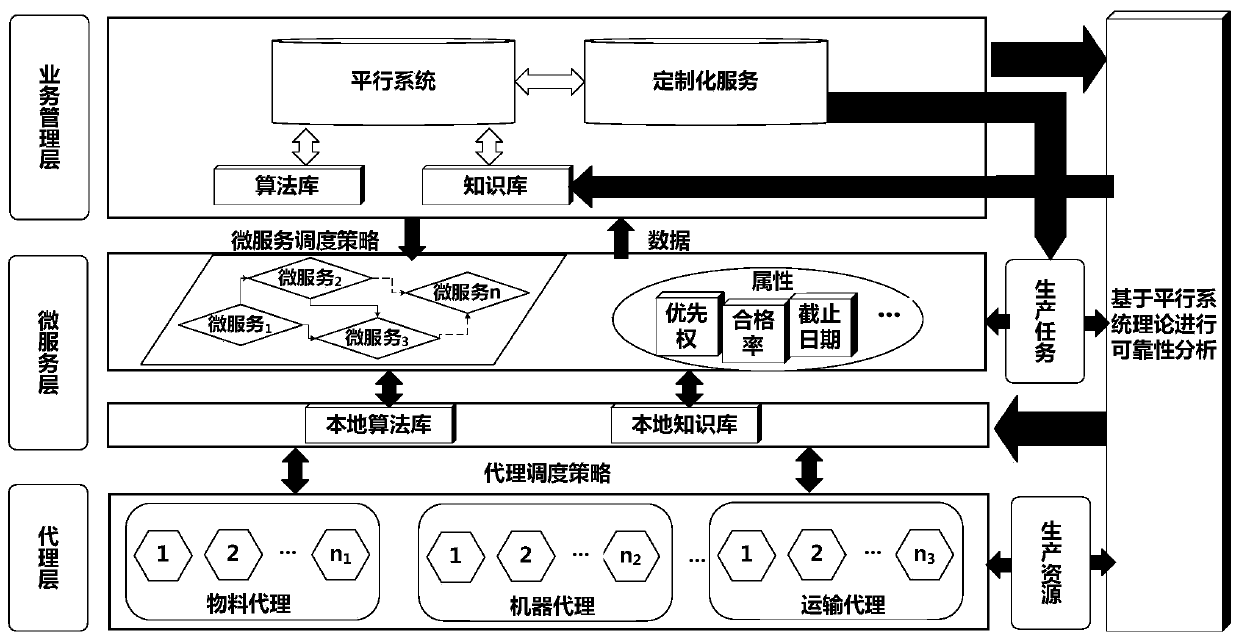

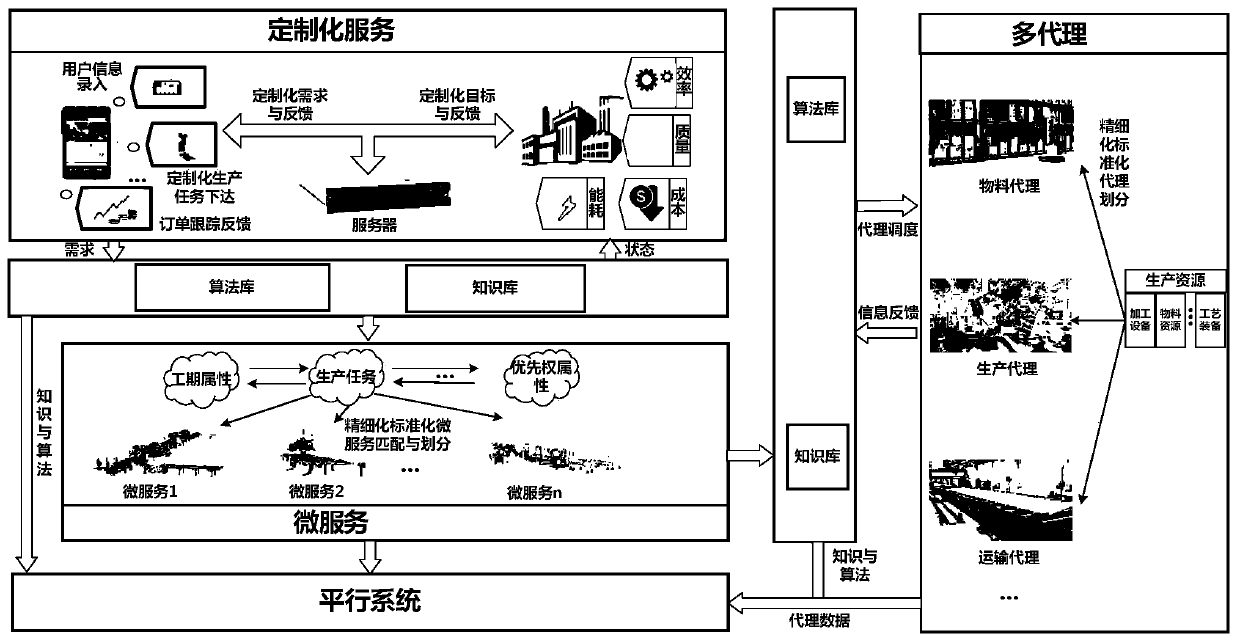

[0020] The overall technical solution of the present invention describes a management and control model of an intelligent factory, and the management and control model includes an agent layer, a micro-service layer, and a business management layer in sequence from bottom to top;

[0021] The agent layer is a multi-agent model for manufacturing resources used in production tasks, including material agents for materials used in production tasks, machine agents for operating machines used in the production line, and transportation agents for completing logistics activities in production tasks; agent information, and complete production tasks under the control strategy of the microservice layer;

[0022] The microservice layer constructs matching rules for microservices in the local knowledge base and algorithm database based on ontology, accepts customized services issued by business management, and establishes them as production tasks including distributed processing microservice...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com