Protection device for power switch in dairy workshop based on gradual temperature control

A workshop power supply and protective device technology, applied in electrical switches, circuits, electrical components, etc., can solve the problems of confusing power switches, affecting work progress, touching parts, and even trigger switches, etc., to avoid normal disassembly and improve use. Uniform effect of life and molding rules

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

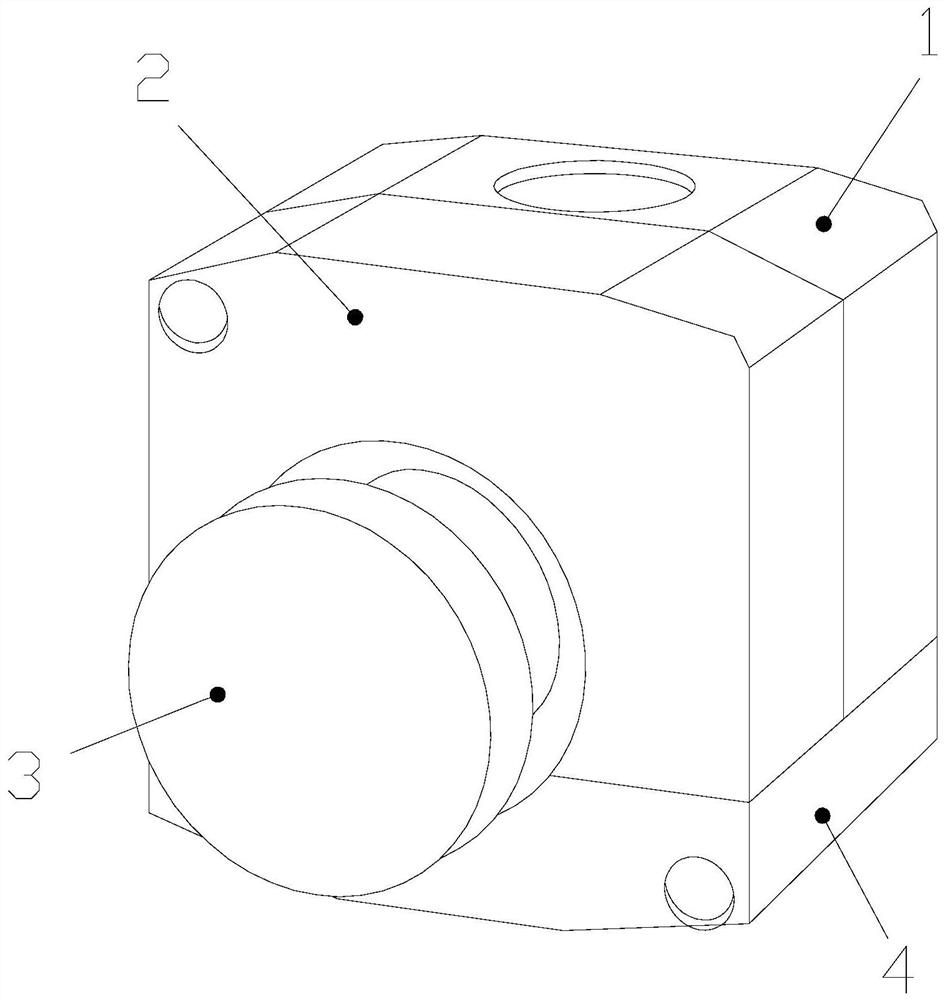

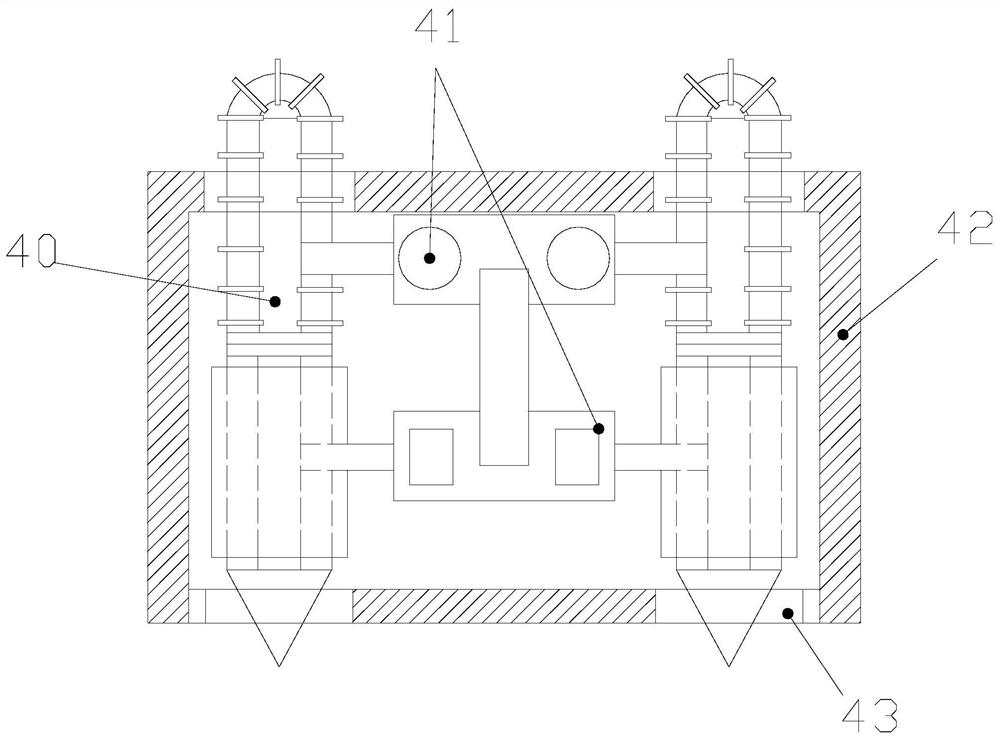

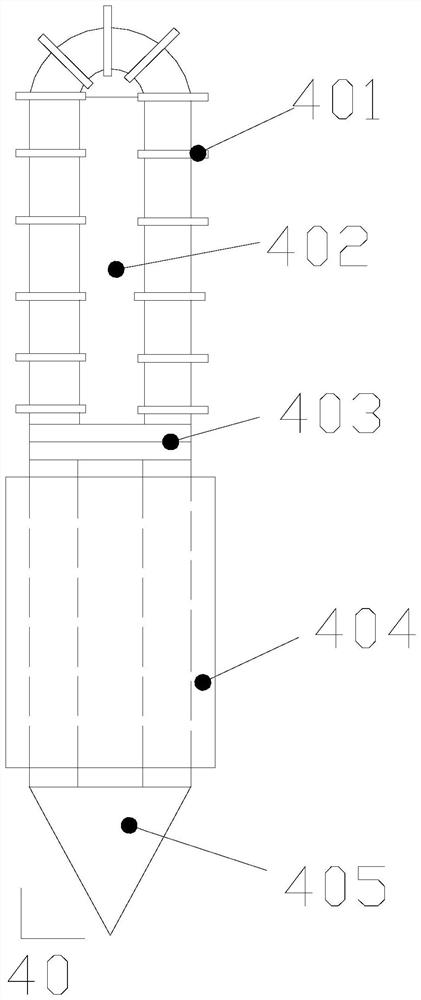

[0028] see figure 1 , the present invention provides a technical solution for a power switch protection device in a dairy workshop based on gradual temperature control: its structure includes a rear cover 1, a front key cover 2, a key 3, and a liquid guiding device 4, and the front end of the rear cover 1 is connected to the front key cover 2. The rear end is fixedly connected by screws. The middle side of the front end of the front key cover 2 is movably connected to the rear end of the key 3. The interior of the key 3 is mechanically connected to the interior of the rear cover 1. The bottom of the rear cover 1 is connected to the liquid guiding device. 4. The top is connected by a card slot. A rubber ring is connected between the rear end of the...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap