Flexible-package cell negative pressure formation method

A flexible packaging and cell technology, used in non-aqueous electrolyte batteries, electrolyte battery manufacturing, sustainable manufacturing/processing, etc., can solve problems such as affecting the contact of pole pieces, reducing the effect of formation, hindering formation, etc., to improve quality and efficiency, avoid adverse effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

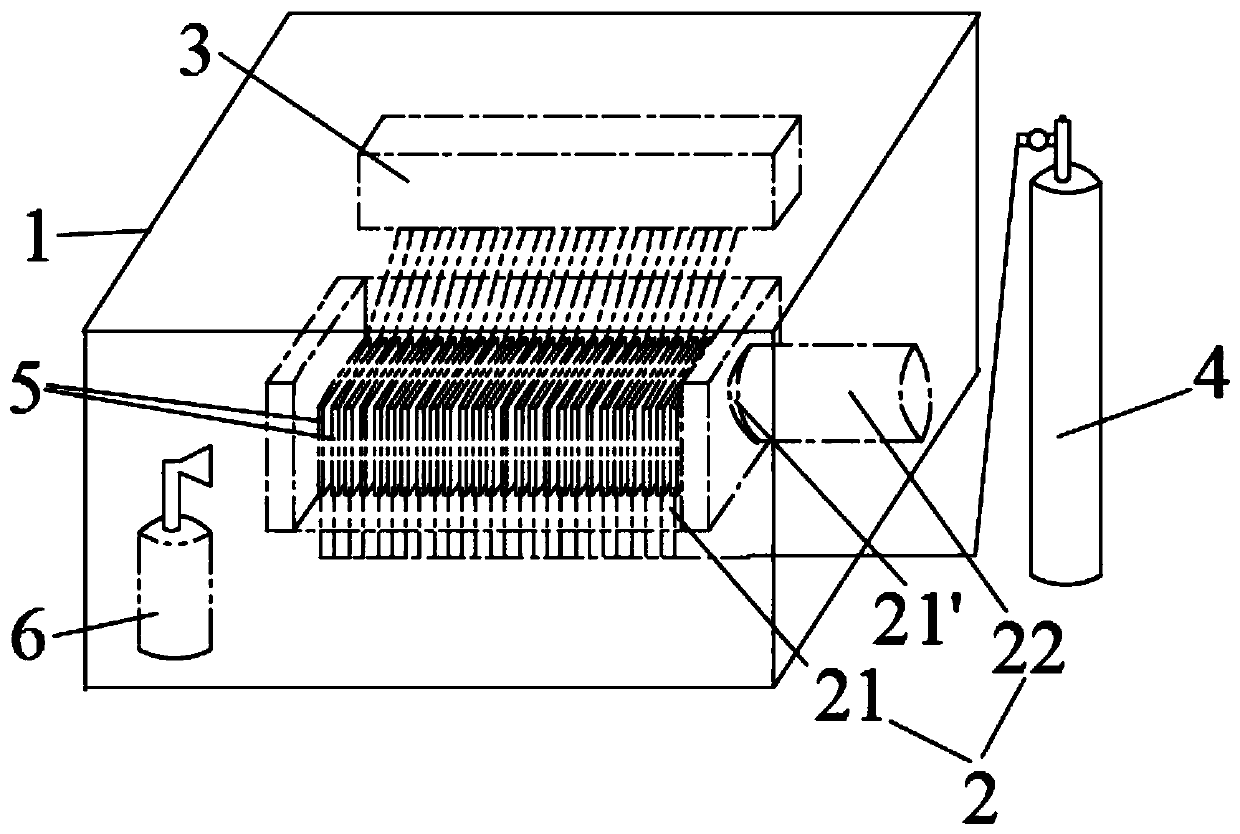

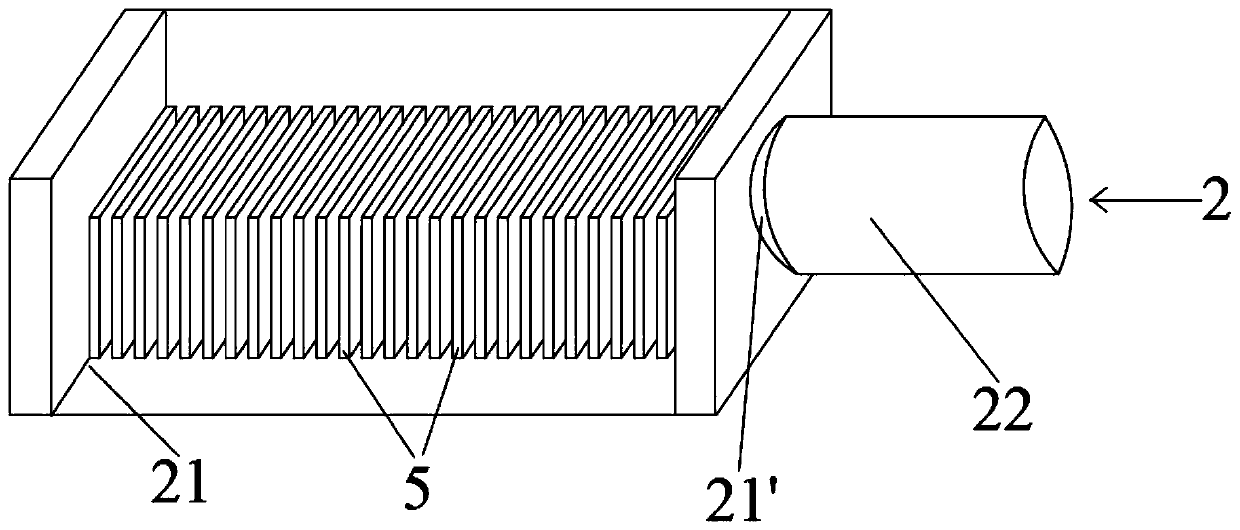

[0032] like Figure 1-2 As shown, a method for the negative pressure formation of flexible packaging cells, including a constant temperature box 1, a fixture module 2, a formation module 3 and a vacuum pump 4, and the fixture module 2 and the formation module 3 are all placed in the constant temperature box 1. The method includes the following steps :

[0033] S1. Place the battery cell 5 in the fixture module 2;

[0034] S2. Adjust the moving parts of the fixture module 2 to pressurize the battery cell 5;

[0035] S3. Connect one end of the pinhole vacuum pipeline to the output end of the vacuum pump 4, and insert the other end of the pinhole vacuum pipeline into the battery cell 5, so that the pinhole vacuum pipeline communicates with the battery cell 5;

[0036] S4. Encapsulate the hole where the pinhole vacuum pipe is inserted into the cell 5;

[0037] S5, open the valve of the vacuum pump 4 to exhaust, so that the inside of the cell 5 is in a negative pressure state; ...

Embodiment 2

[0048] like Figure 1-2 As shown, the difference from Embodiment 1 is that in this embodiment, in step S5, the valve of the vacuum pump 4 is regularly opened for exhaust. This can be used as an operation mode to maintain the negative pressure in the battery cell 5 .

[0049]Other structures and methods are the same as those in Embodiment 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com