Metal button automatic aligning and hanging device and method

An automatic alignment and suspension device technology, applied in the electrolysis process, electrolysis components, etc., can solve the problems of low life of the suspension mechanism and the hanger, large impact and loud noise of the suspension mechanism and the hanger, to prevent impact damage, automatic Alignment, low noise effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with accompanying drawing:

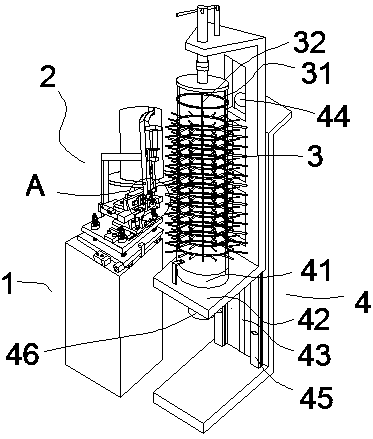

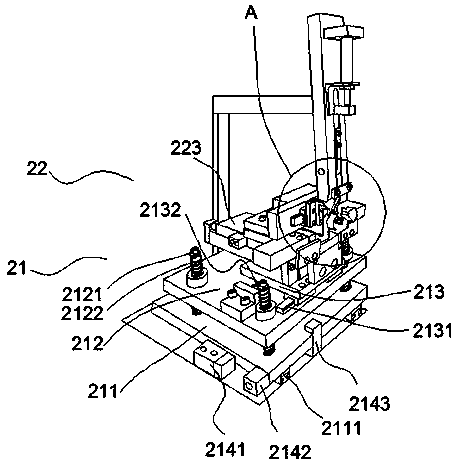

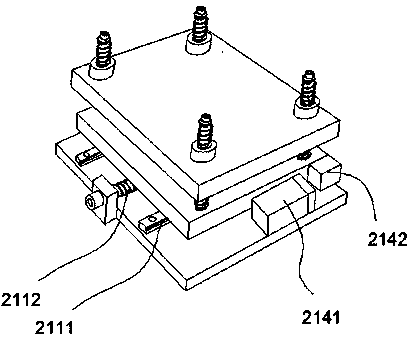

[0033] As shown in Figures 1-8, this embodiment provides a metal button automatic alignment suspension device 2, which is installed on the chassis 1 on one side of the hanger 3. The automatic alignment suspension device 2 includes a flexible support 21, a lock Tightening mechanism and suspension mechanism, the suspension mechanism slides back and forth on the top of the flexible support 21 and includes a sliding plate 223, a propulsion assembly 22 that drives the sliding plate 223 to slide back and forth, and an openable guide sleeve that is movably arranged at the front end of the sliding plate 223 and The elastic clip material assembly that can be opened and closed, the closed position of the guide sleeve is directly in front of the center of the elastic clip material assembly, the hanger 3 is installed on the hanger action device 4, and the hanger 3 includes four pillars ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap