Suspension conduit bridge tunnel type anchorage main cable anchoring system

An anchoring system and tunnel-type technology, used in bridges, bridge materials, bridge construction, etc., can solve problems such as good integrity, failure to meet design requirements, and few rock mass joints, reducing excavation size, reducing disturbance, The effect of improving the safety factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

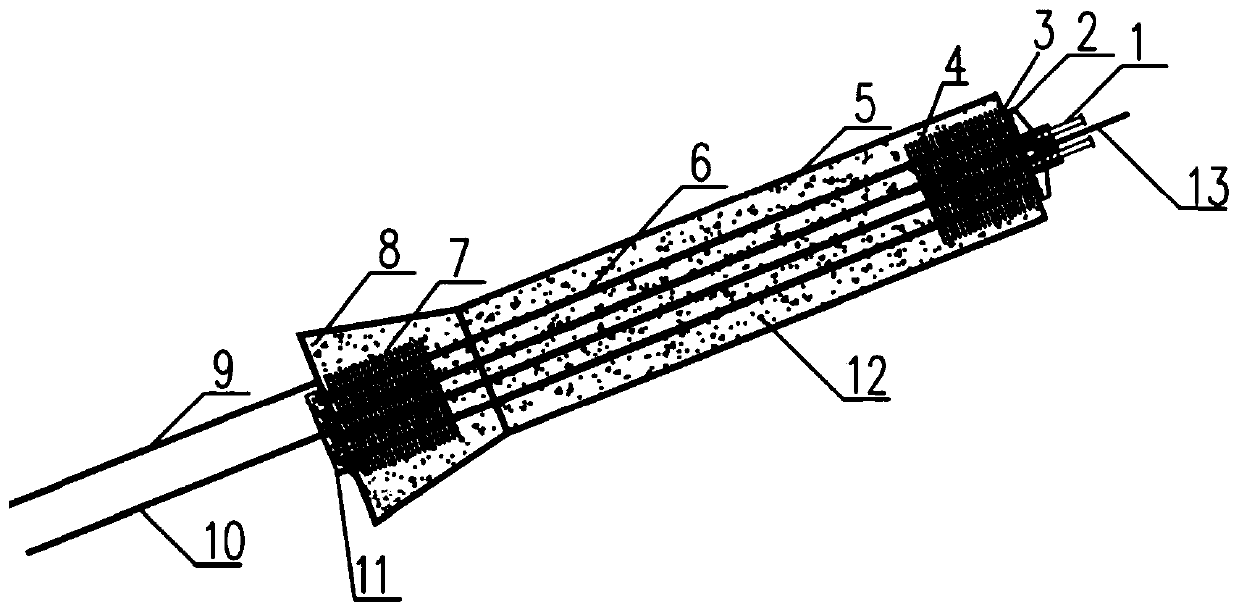

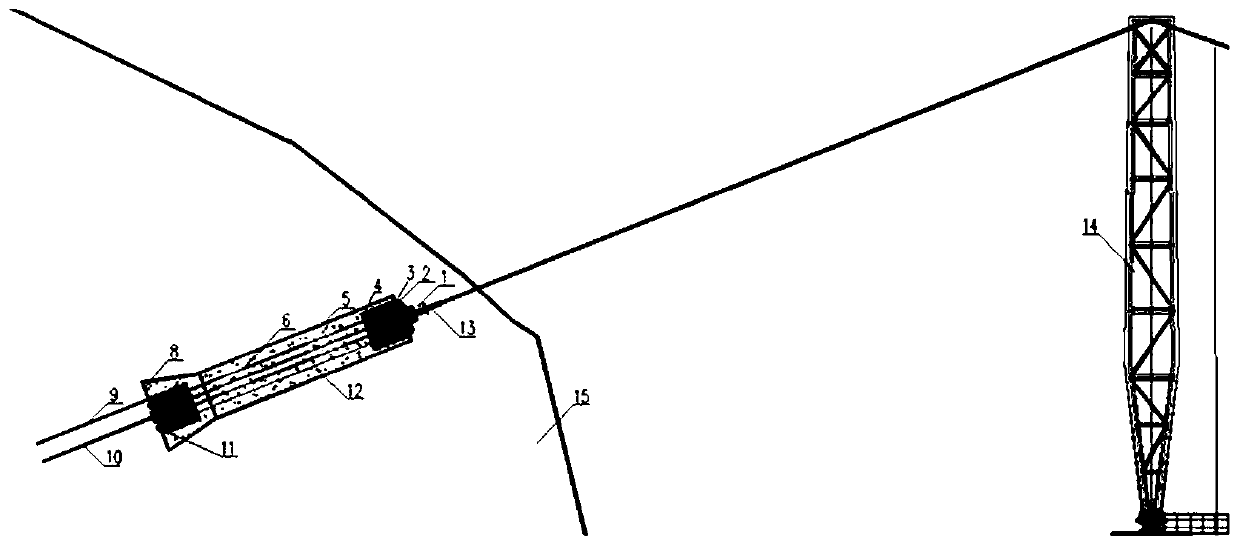

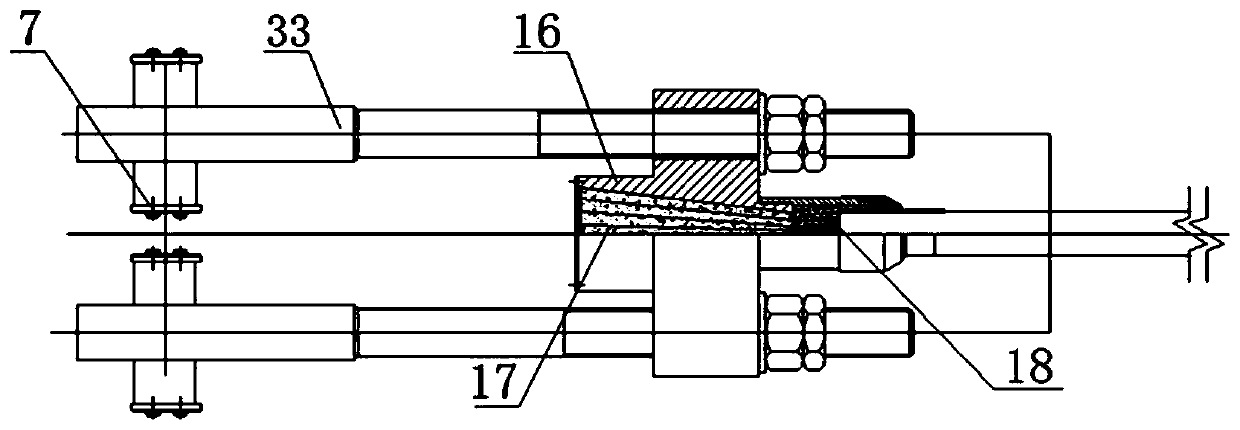

[0044] The invention is applied to a suspension pipeline bridge with a main span length of 355m and a main cable rise-span ratio of 1 / 10 to transport a gas pipeline with a diameter of Ф1016mm and a water pipeline with a diameter of D150mm. The suspension pipeline bridge includes 2 sets of main cables, each with a spacing of 3m; each set of main cables is composed of 2 PES5×265 twin-screw main cables, and the spacing between each main cable is 550mm. The main cable on the east bank of the pipeline bridge adopts a gravity-type anchorage pier, and the anchoring position of the main cable on the west bank has a steep slope. The tunnel anchorage method is adopted. The length of the tunnel anchorage section is 35m, and the section is horseshoe-shaped. 7.8×9.1m, section width 7.5m, upper arch diameter 7.8m, straight section height 6m, gradient section bottom height 9.1m. Set the prestressed rock on the back side of the tunnel anchor, and set 8 bundles of prestressed anchor cables, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com