Hydraulic natural gas compressor intake system, secondary fueling station and gas discharge method

A technology of hydraulic natural gas and air intake system, which is applied to liquid variable volume machinery, mechanical equipment, machines/engines, etc. problems, to achieve the effect of reducing operating costs, improving operating efficiency, and improving air discharge rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Typical embodiments that embody the features and advantages of the present invention will be described in detail in the following description. It should be understood that the present invention is capable of various changes in different embodiments without departing from the scope of the present invention, and that the description and illustrations therein are illustrative in nature and not limiting. this invention.

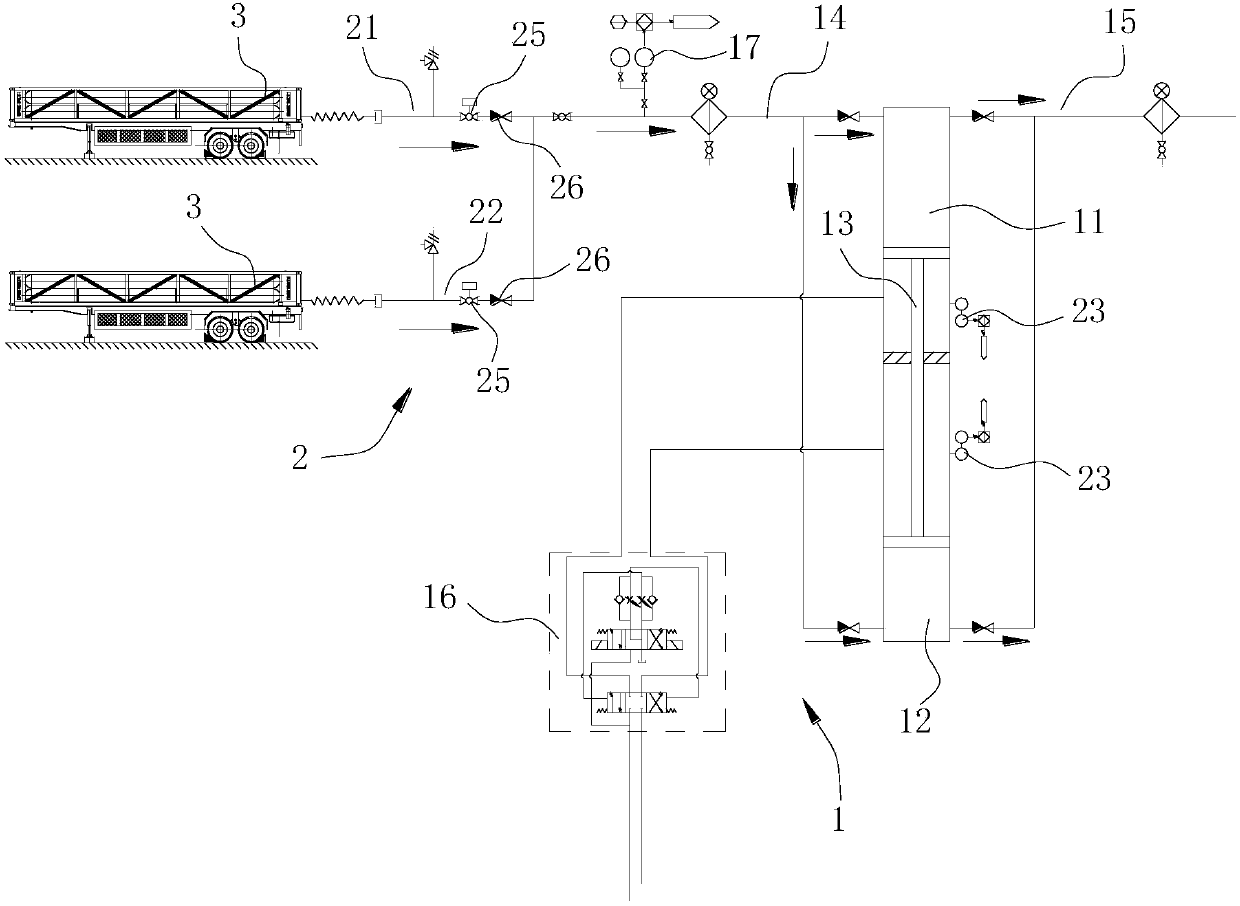

[0024] The present invention provides a hydraulic natural gas compressor air intake system (hereinafter referred to as "intake system"), and a hydraulic natural gas compressor gas filling substation (hereinafter referred to as "gas filling substation") having the air intake system. The system is used to control the intake of the hydraulic natural gas compressor (hereinafter referred to as "compressor") in the gas filling substation. In addition, the invention also provides a gas unloading method for the gas filling substation.

[0025] like figure 1 As ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com