Commercial vehicle brake pad

A technology for brake pads and commercial vehicles, which is applied to friction linings, slack adjusters, mechanical equipment, etc., to achieve the effect of enhancing the appearance and reflection of strong light and shadow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

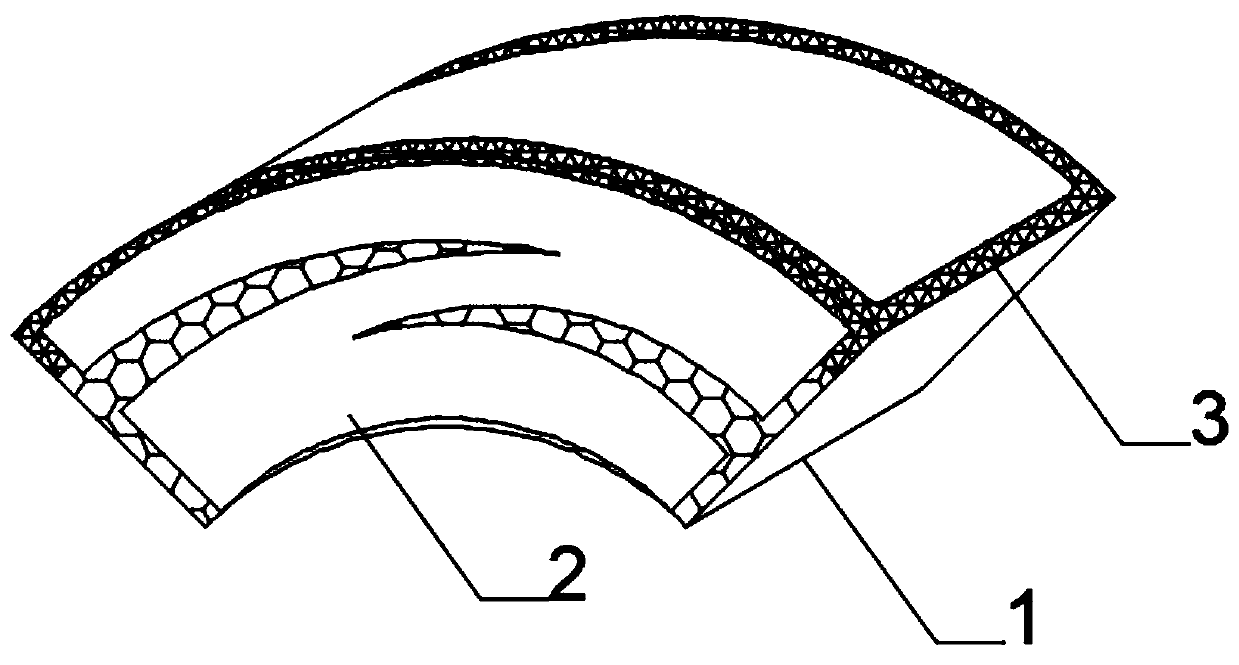

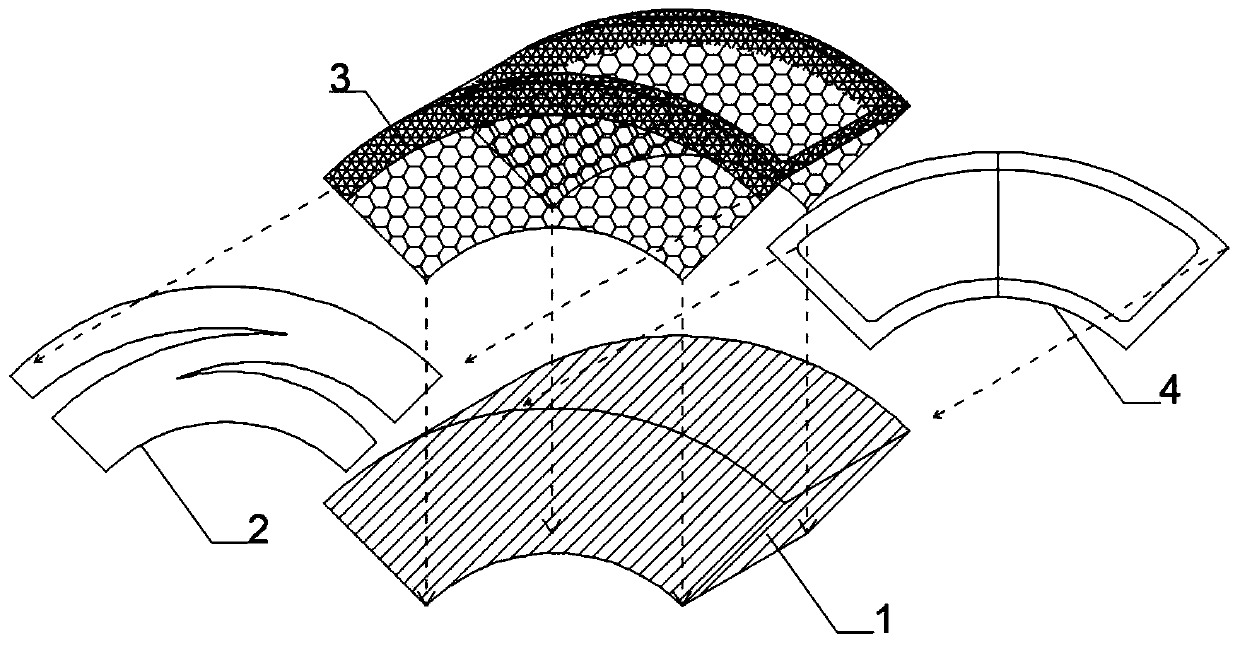

[0027] as attached figure 1 To attach Figure 5 Shown:

[0028] The present invention provides a commercial vehicle brake pad, including a brake pad base 1, a surface gasket 2, a penetration frame 3 and a partition contact surface 4; the outer surface of the brake pad base 1 is connected by screws and a penetration frame 3 is installed; the penetration frame The outer side of 3 is connected by screws and installed with surface gasket 2; the inner side of the brake pad base 1 is connected by glue and fixed with partition contact surface 4.

[0029] Wherein, the brake pad base 1 has an arc-shaped pad structure as a whole.

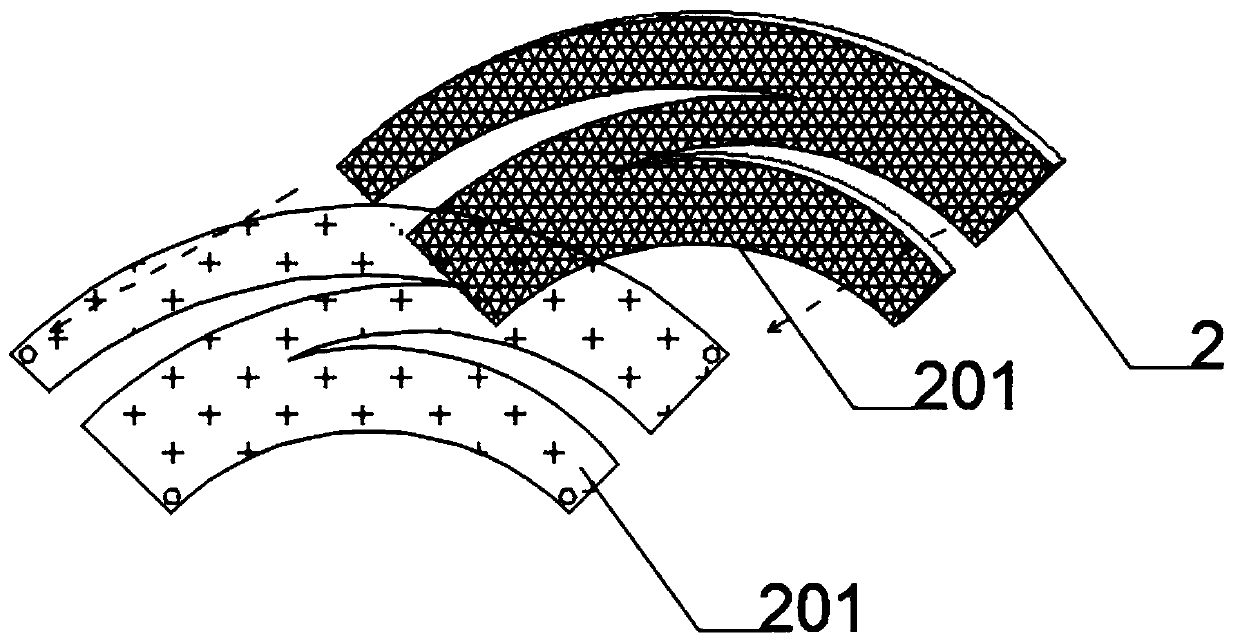

[0030] Wherein, the surface gasket 2 has an S-like structure as a whole, and the area of the surface gasket 2 is equal to 75% of the side area of the brake pad base 1; the surface gasket 2 is equipped with a light-transmitting reflective structure 201; The light-transmitting reflective structure 201 is composed of two layers, the bottom layer is a fine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com