Pilot type pneumatic solenoid valve

A pneumatic solenoid valve and pilot-operated technology, applied in the field of solenoid valves, can solve problems such as heavy mass, low synchronization, and slow response time, and achieve the effects of weight reduction, slow response time, and high magnetic flux utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

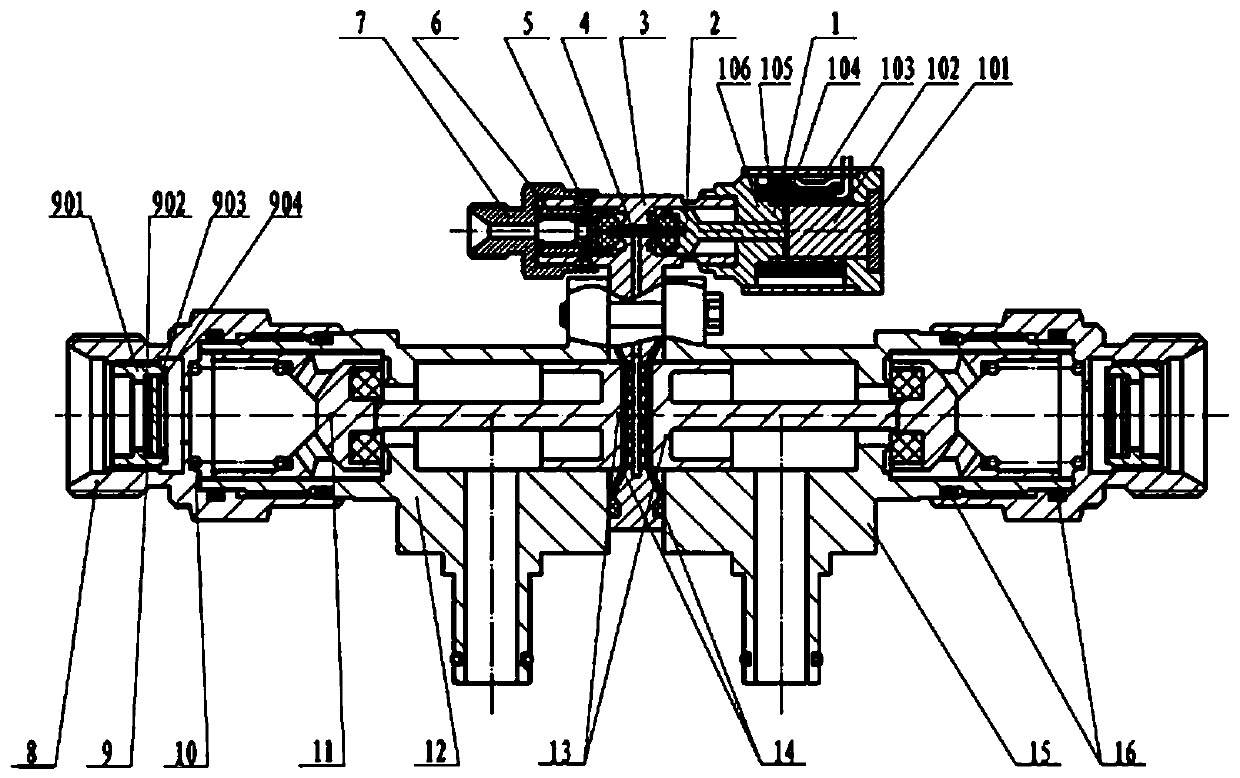

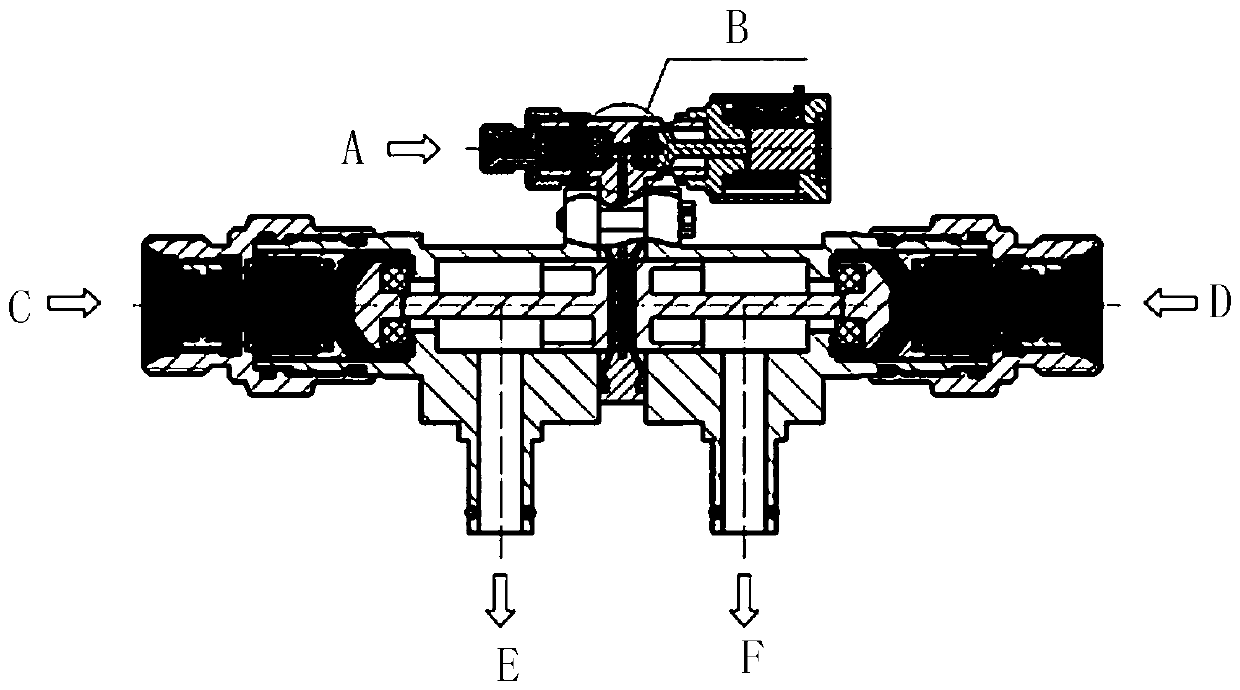

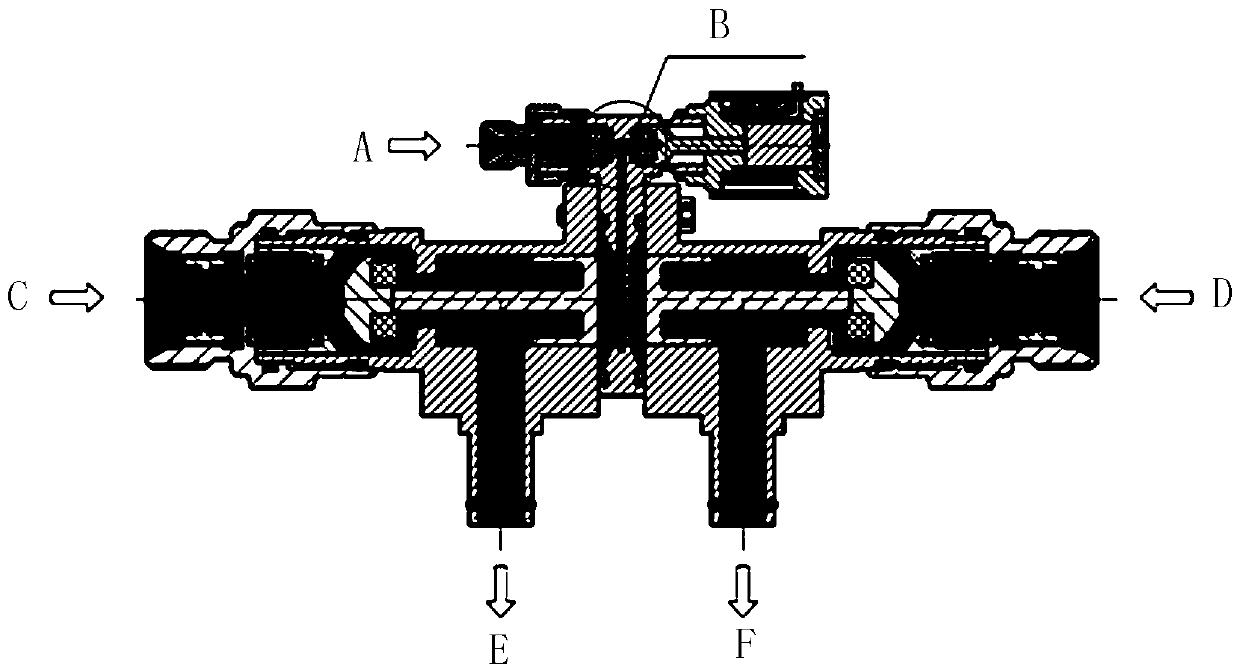

[0018] As shown in the figure, a pilot-operated pneumatic solenoid valve includes a solenoid valve assembly 1, an air push rod 2, a bracket 3, an air valve core 5, a liquid valve core 11, a filter screen assembly 9, a connecting rod 4, and an air circuit spring 6 , Gas nozzle 7, liquid nozzle 8, liquid spring 10, liquid push rod 13, liquid housing Y12, liquid housing R15, sealing rubber ring 16 and rubber pad 14.

[0019] The solenoid valve assembly 1 is a magnetic field forming mechanism, including a housing 106 welded by magnetic materials and stainless steel, a coil 105 wound on the outer wall of the housing for generating a magnetic field, and a casing that is placed outside the coil to form a magnetic field circuit 103, the magnetic valve core 102 set in motion in the housing, the magnetic isolation spacer 104 providing the magnetic isolation effect is installed at one end of the magnetic valve core 102, and the spiral ring 101 is installed at the end of the housing for co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com