Raw material cutting device for machining and operation method thereof

A technology of mechanical processing and cutting equipment, which is applied in the direction of metal processing equipment, metal processing, metal processing machinery parts, etc., and can solve problems such as affecting the normal operation of the equipment, generating a large amount of waste, shortening the service life of the equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

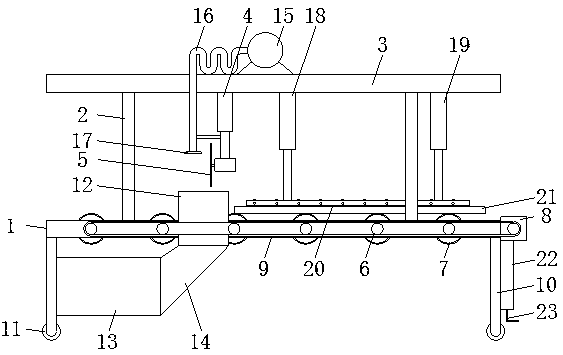

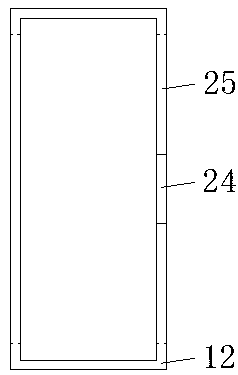

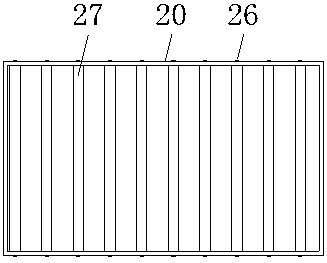

[0036] A raw material cutting equipment for mechanical processing, comprising a frame 1, the top of the frame 1 is connected to a top plate 3 through a pillar 2, the bottom of the top plate 3 is connected to a cutting machine 5 through a first cylinder 4, and the surface of the frame 1 is passed through a first The rotating shaft 6 is connected with the first transmission roller 7 in rotation, the side of the frame 1 is equipped with a brake motor 8, the output shaft of the brake motor 8 drives the first rotating shaft 6 to rotate through the transmission belt 9, the top of the frame 1 corresponds to the position of the cutting machine 5 A splash guard 12 is installed, and the bottom of the splash guard 12 communicates with a collection box 13 through a communication pipe 14 .

[0037] This technical solution automatically conveys and fixes the raw material 21, and cuts the raw material 21 by the cutting machine 5, and restricts the waste chips through the splash guard 12 after...

Embodiment 2

[0039] A raw material cutting equipment for mechanical processing, comprising a frame 1, the top of the frame 1 is connected to a top plate 3 through a pillar 2, the bottom of the top plate 3 is connected to a cutting machine 5 through a first cylinder 4, and the surface of the frame 1 is passed through a first The rotating shaft 6 is connected with the first transmission roller 7 in rotation, the side of the frame 1 is equipped with a brake motor 8, the output shaft of the brake motor 8 drives the first rotating shaft 6 to rotate through the transmission belt 9, the top of the frame 1 corresponds to the position of the cutting machine 5 A splash guard 12 is installed, the bottom of the splash guard 12 communicates with a collection box 13 through a connecting pipe 14, the bottom of the frame 1 is welded with a support leg 10, and the bottom of the support leg 10 is rotatably connected with a pulley 11, and the collection box 13 is installed on The surface of the leg 10.

[00...

Embodiment 3

[0042]A raw material cutting equipment for mechanical processing, comprising a frame 1, the top of the frame 1 is connected to a top plate 3 through a pillar 2, the bottom of the top plate 3 is connected to a cutting machine 5 through a first cylinder 4, and the surface of the frame 1 is passed through a first The rotating shaft 6 is connected with the first transmission roller 7 in rotation, the side of the frame 1 is equipped with a brake motor 8, the output shaft of the brake motor 8 drives the first rotating shaft 6 to rotate through the transmission belt 9, the top of the frame 1 corresponds to the position of the cutting machine 5 A splash guard 12 is installed, the bottom of the splash guard 12 communicates with a collection box 13 through a connecting pipe 14, the bottom of the frame 1 is welded with a support leg 10, and the bottom of the support leg 10 is rotatably connected with a pulley 11, and the collection box 13 is installed on The surface of supporting leg 10, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com