Hydraulically-driven hydrogen compressor

A compressor and hydrogen technology, applied in the field of compressors, can solve problems such as shortened service life and insufficient stability of hydrogen output pressure, and achieve the effects of shortened service life, stable hydrogen output pressure, and improved compression capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

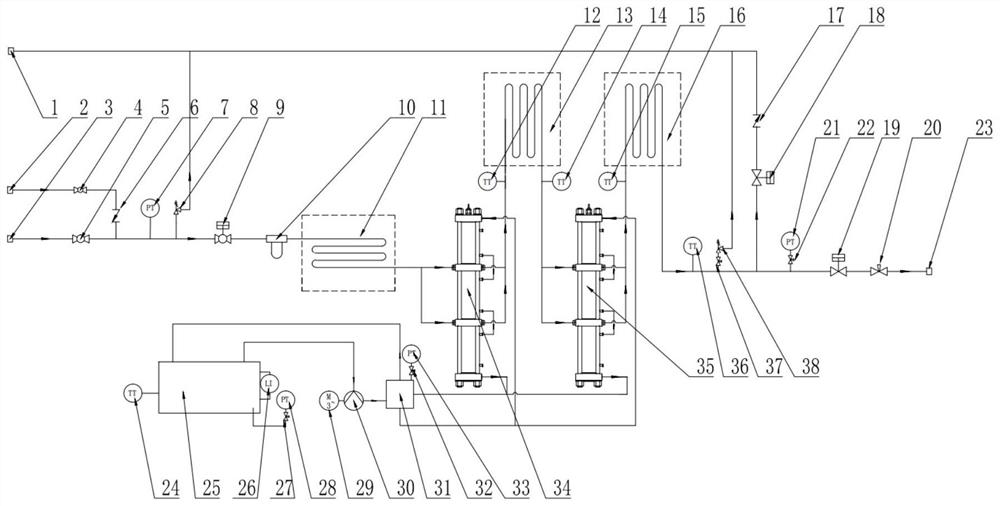

[0023] The preferred embodiments of the present invention are specifically described below with reference to the accompanying drawings, wherein the accompanying drawings constitute a part of the present application, and together with the embodiments of the present invention, are used to explain the principles of the present invention, but are not used to limit the scope of the present invention.

[0024] Please refer to figure 1 , an embodiment of the present invention provides a hydraulically driven hydrogen compressor, including: a gas circuit and an oil circuit;

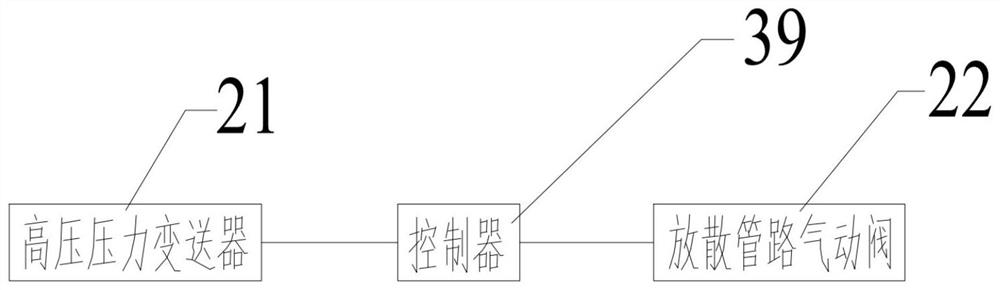

[0025] The gas circuit includes a low-pressure hydrogen pipe port 3, a hydrogen pipe ball valve 5, an air intake pipe pneumatic valve 9, a pre-compression cooler 11, a primary piston compression cylinder 34, a primary cooling assembly 13, and a secondary piston. The compression cylinder 35, the secondary cooling assembly 16, the pneumatic valve 19 of the exhaust pipeline and the exhaust pipe port 23; wherein, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com