Anti-skidding device applied to automobile tires

An anti-skid device, a technology for automobile tires, applied in the directions of wheels, wheel accessories, wheel adhesion, etc., can solve the problems of destroying the road surface, polluting the environment, and reducing the service life of snow chains

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

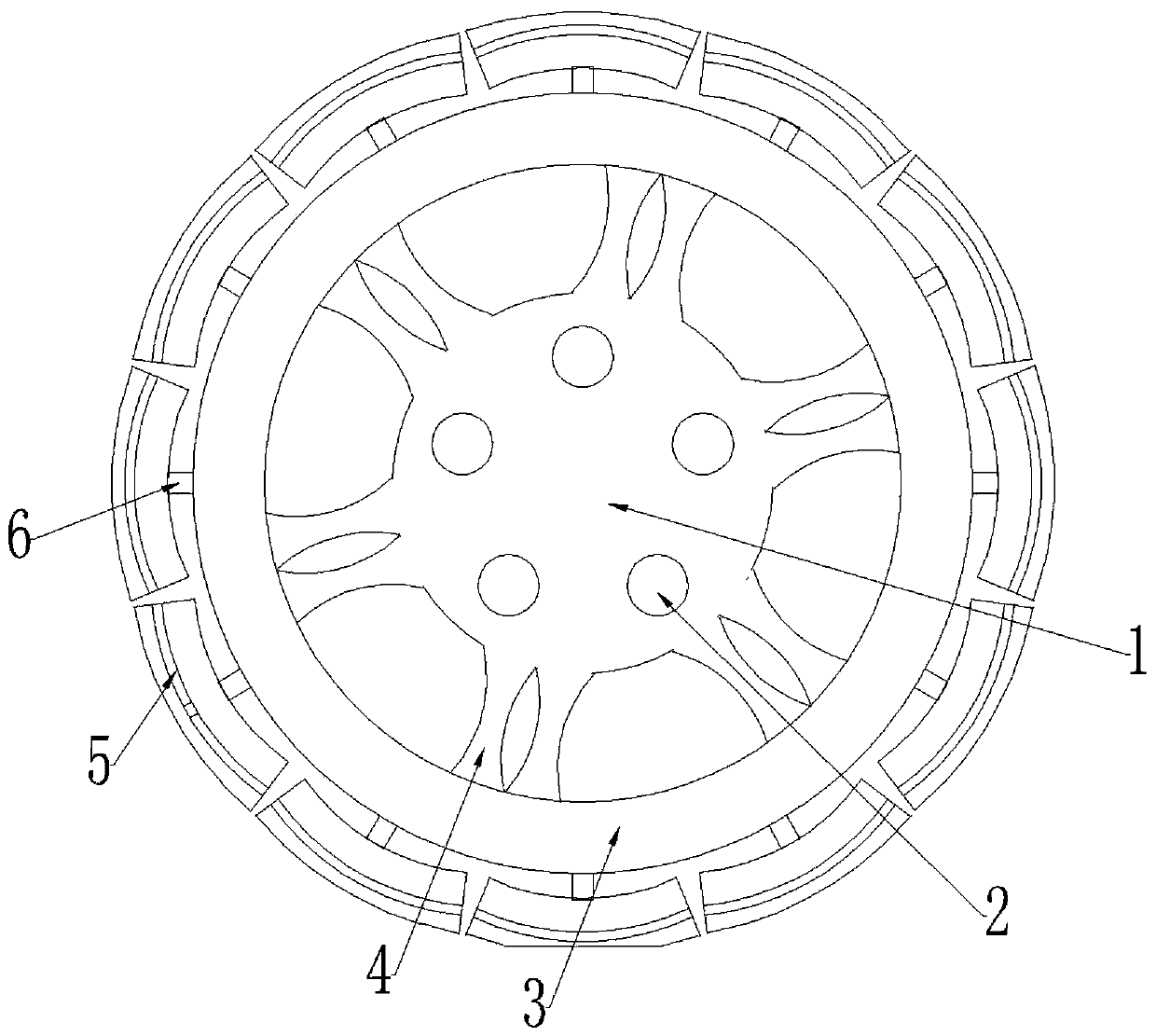

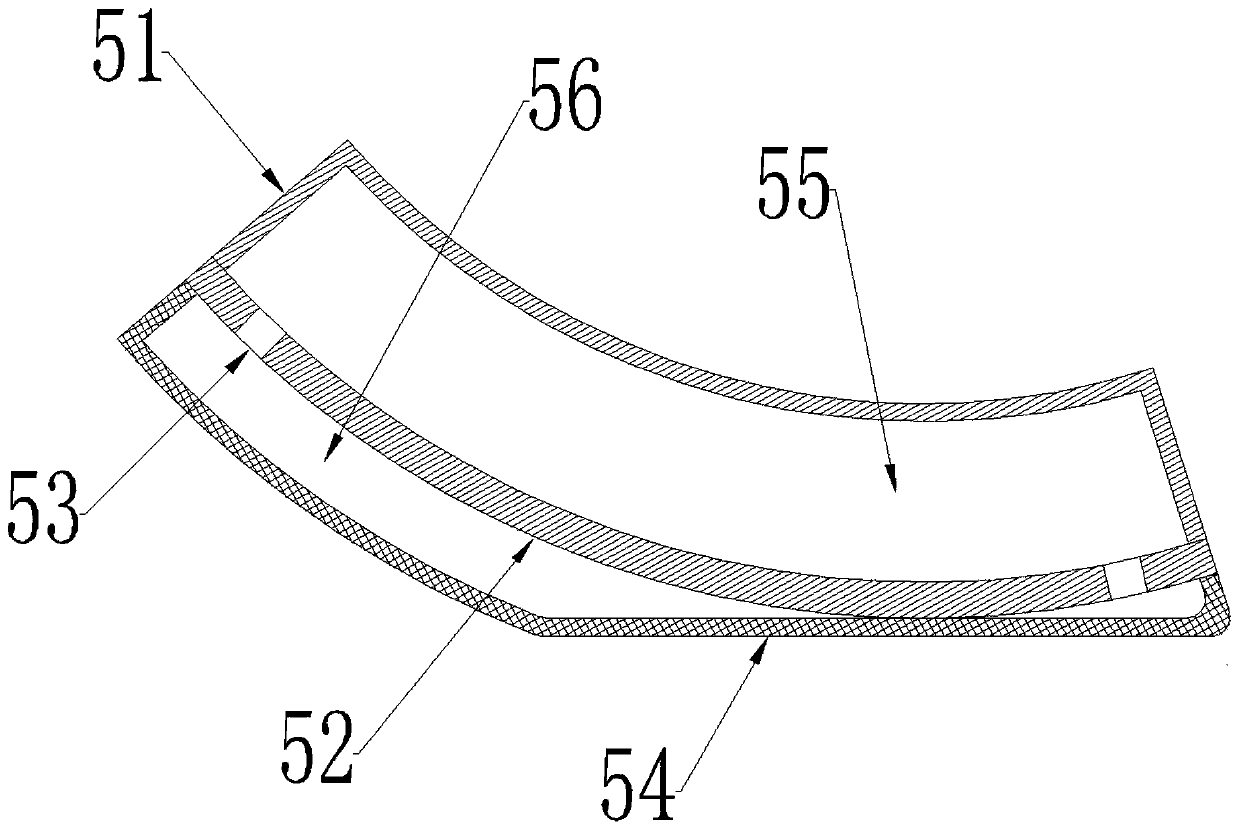

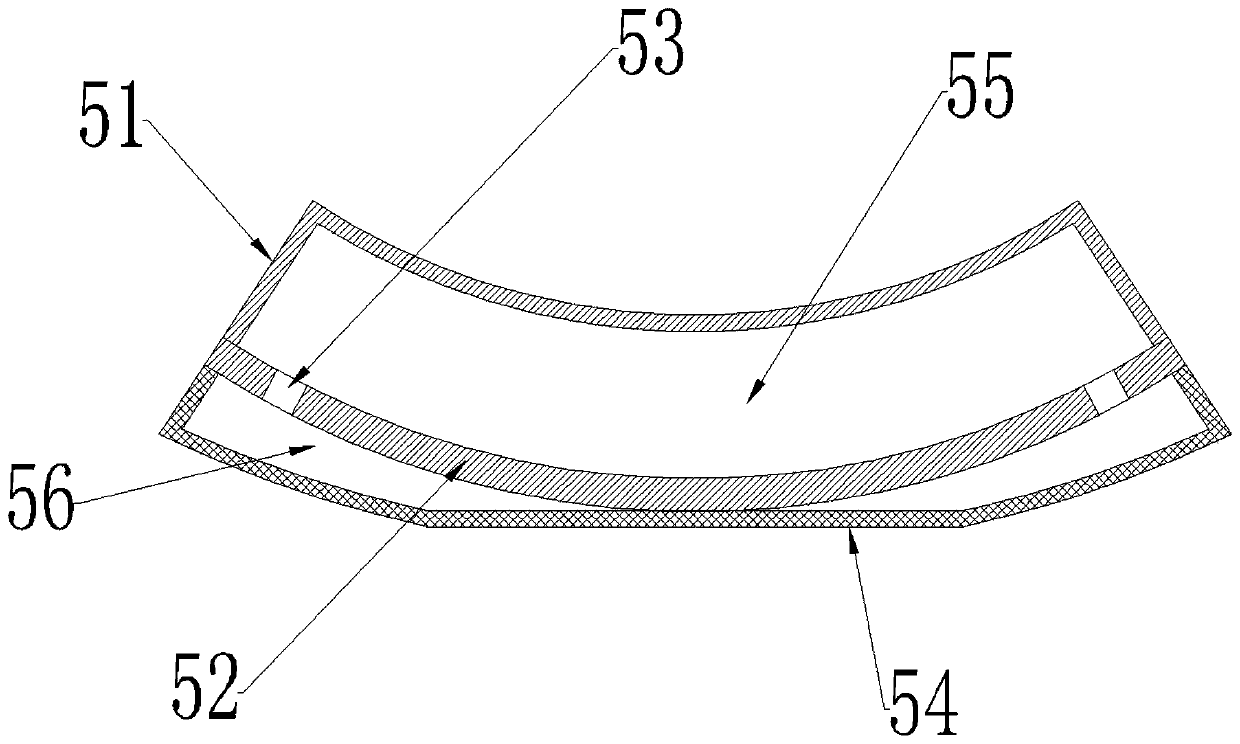

[0037] Such as figure 1 Shown, a kind of anti-skid device for automobile tires comprises internal fixed hub 1, and described internal fixed hub 1 is provided with the mounting hole 2 that connects wheel; The lengthened screw rod fixes the inner fixed hub 1 and the wheel hub together. An outer support hub 3 is arranged outside the inner fixed hub 1 , and connecting spokes 4 are arranged between the inner fixed hub 1 and the outer support hub 3 . Several anti-slip unit bodies 5 are fixed on the outer wall of the outer support hub 3, such as figure 2 and image 3 As shown, the anti-skid unit body 5 includes a support body 52, the cross section of the support body 52 is arc-shaped and the inner concave surface of the support body 52 faces the outer support hub 3; several support bodies 52 with equal inner diameters Evenly distributed on the outer side of the outer support hub 3, several support bodies 52 form a ring together, surround the outer side of the outer support hub 3,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com