Novel automatic rotary push device

A technology of automatic rotation and pushing devices, applied in the direction of lifting devices, etc., can solve the problems of time-consuming and laborious work efficiency, low degree of automation, and restrictions on the development of the handling industry, so as to save time and physical strength and improve work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described below in conjunction with the accompanying drawings.

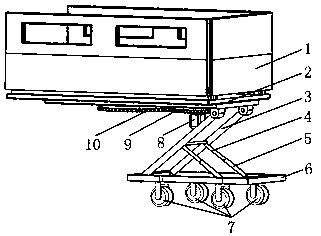

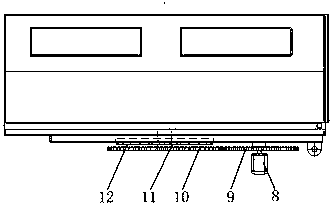

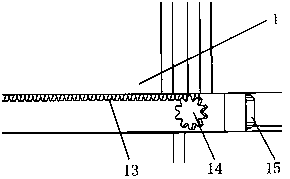

[0010] Such as figure 1 , figure 2 with image 3 As shown, a new type of automatic rotary pushing device according to the present invention includes a pallet box 1, a support plate 2, a support rod 3, a hydraulic rod 4, a hydraulic cylinder 5, a base 6, wheels 7, a large gear 8, a middle gear 9. Stepping motor 10, buckle 11, working gear 12, rack 13, pinion 14, servo motor 15; the wheels 7 on the base 6 are used for the transportation of the whole mechanism; the hydraulic rod 4 and the hydraulic cylinder 5 telescopic cooperation realizes the adjustment effect of the support rod 3 on the support plate 2; the retraction action of the buckle 11 on the rotating shaft of the working gear 12, the working gear 12 enters the support plate 2, and at this time the large gear 8 passes through and the middle gear 9 The meshing movement starts to work; the stepper motor 10 driv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com