A cylindrical cathode device with magnetic shoe that can move in real time

A magnetic shoe and column type technology, which is applied in the field of magnetron sputtering coating equipment, can solve the problems that the control of columnar magnetron sputtering cathode and columnar arc ion plating magnetic shoe is difficult to achieve, and achieve air intake and sealing sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

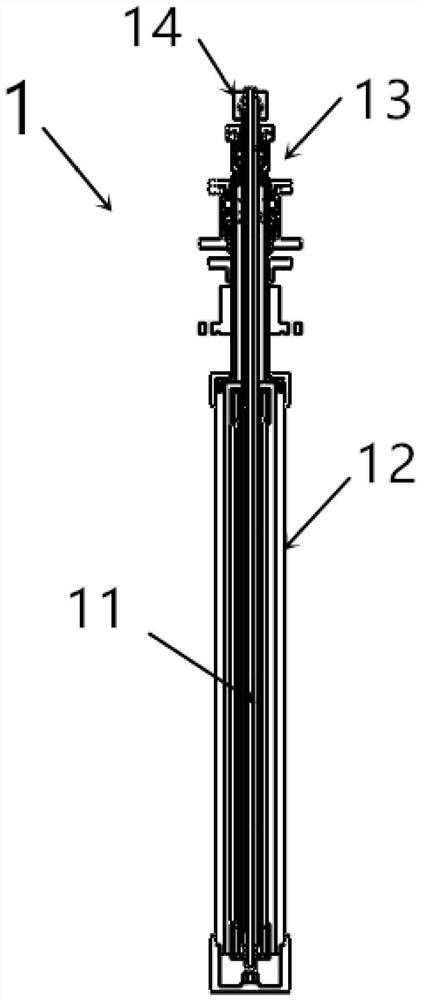

[0040] Such as Figure 2-Figure 10 As shown, a cylindrical cathode device with a magnetic shoe that can be moved in real time includes an air-push magnetic shoe 11, a target tube assembly 12, a target head assembly 13, and an air inlet sealing seat 14; wherein:

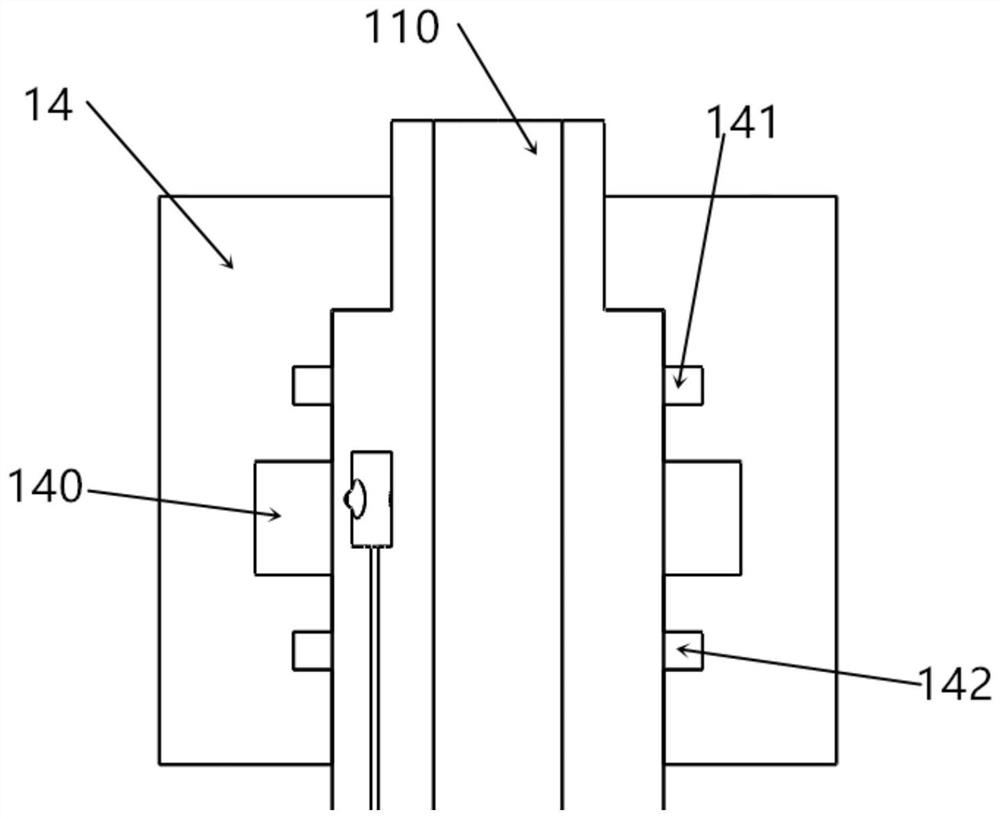

[0041]The air-push magnetic shoe 11 includes a water-air core 110, a rubber ring 111, an upper and lower threaded sleeve 115, a locking ring 112, an upper and lower gland 114, and a magnetic yoke 113; the rubber ring 111 is set on the water-air core 110, the upper and lower ends of the outer edge of the rubber ring 111 are bonded to the upper and lower threaded sleeves 115; the snap ring 112 and the yoke 113 are symmetrically bonded to the rubber ring 111; the upper and lower The gland 114 is assembled on the upper and lower threaded sleeves 115;

[0042] The target tube assembly 12 includes a shield cover, an insulating sleeve, a target tube 122, a target tube upper connecting tube 120 and a target tube upper and lo...

Embodiment 2

[0056] The main difference between Embodiment 2 and Embodiment 1 is that an external arc striking device with a rotating cylinder (common structure, not shown) is required, and the other parts are the same in structure and will not be repeated here.

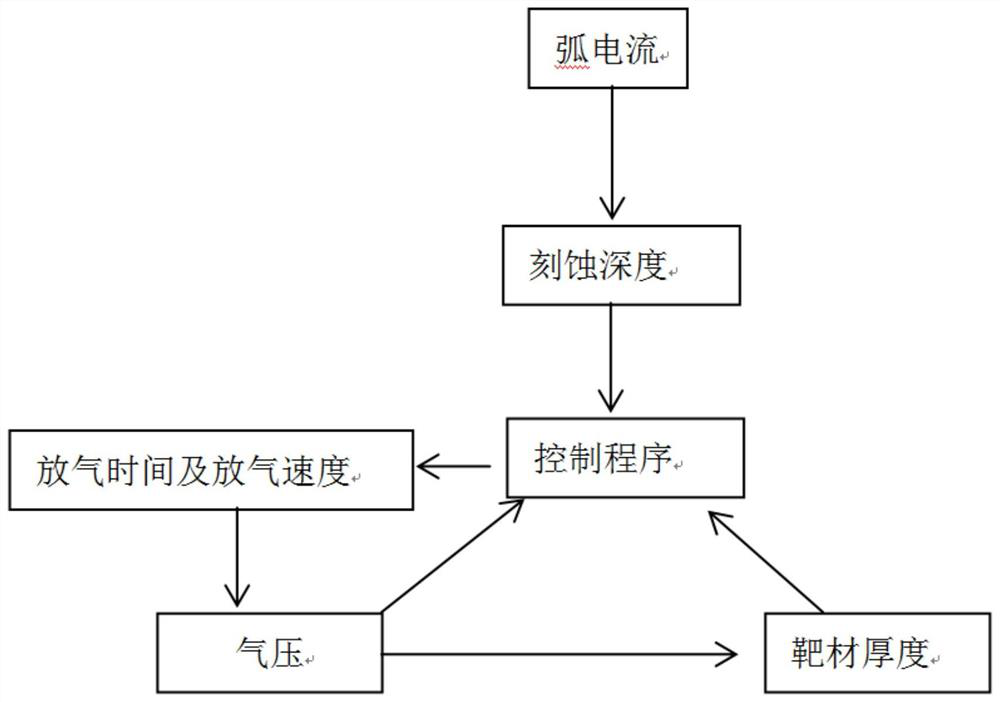

[0057] During the working process of air-push columnar rotary arc ion plating, in the initial state, the air pressure in the expansion chamber 03 is the largest, and the yoke 113 is attached to the upper and lower glands 114 by the air pressure, and then in the actual use process, it can be adjusted according to the type of target material. (Thickness), arc current calculation to obtain the etching speed and etching depth of the target, and set the deflation time and rate of the flow deflation valve, so as to realize the position of the magnetic shoe in the cathode during the discharge process of the arc ion plating target Changes in real time.

[0058] The invention is a new type of cylindrical cathode which can be moved by magn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com