A slope support mechanism and its construction method

A technology for slopes and slopes, which is applied in the direction of basic structure engineering, excavation, construction, etc., can solve the problems that the retaining wall frame is easy to peel off from the slope body, the anchor is not firmly anchored, and it is not easy to be coaxial with the hole, etc., to achieve Enhanced mechanical properties and corrosion resistance, firm anchorage, and the effect of preventing slope collapse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

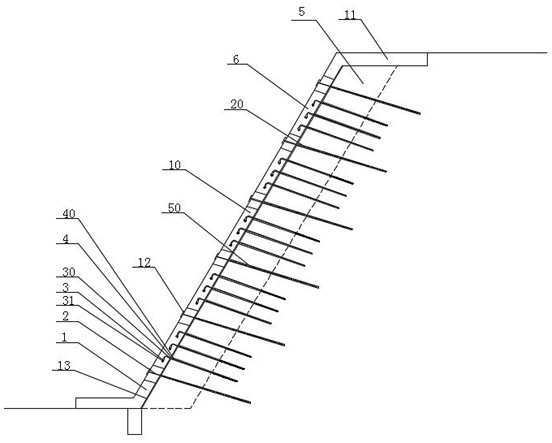

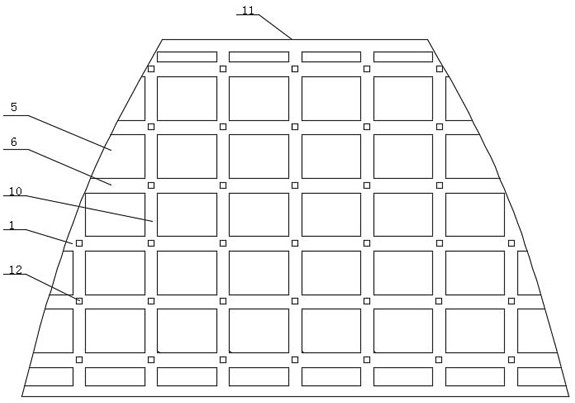

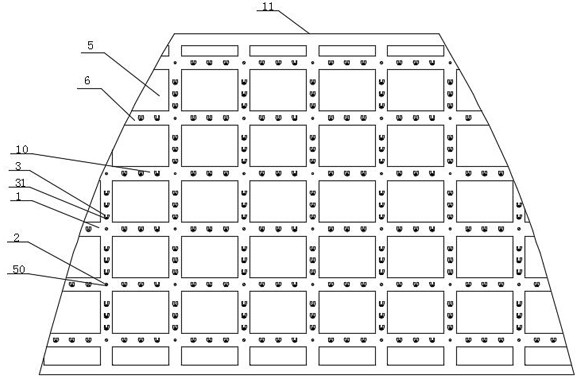

[0040] Example 1, such as Figure 1-10 As shown, the slope support mechanism includes a support frame 1 and an anchor rod 2. The support frame 1 is composed of an inclined part 10 and a horizontal part 11. Concrete frame, the upper end of the inclined part 10 is horizontally provided with an upper extension end, and the upper extension end is placed on the top of the slope body 5, and the lower end of the inclined part 10 is horizontally provided with a lower extension end, and the lower extension end is placed at the bottom of the slope body 5. The extension end and the lower extension end form a horizontal part 11, and blind holes 50 inclined downward are evenly opened on the outer surface of the slope body 5, and the lower end of the anchor rod 2 is anchored in the blind hole 50 of the slope body 5, and the upper end is embedded in the support frame In the concrete protrusion 12 at the center of each of the four adjacent grids 6 of 1, elastic protective sleeves 20 are evenl...

Embodiment 2

[0051] Embodiment 2, the difference with embodiment 1, such as Figure 11 As shown, the inner surface of the support frame 1 is bonded with a metal mesh 13, and the metal mesh 13 is close to the outer surface of the slope body 5; the advantage is that the metal mesh 13 prevents the exposed debris in the grid 6 of the support frame 1 The sliding of rocks and easy-to-fall rock formations plays a better role in reinforcing the slope 5.

[0052] The construction method of described slope support mechanism, its steps comprise:

[0053] A, uniformly drill a plurality of blind holes 50 inclined downward on the outer surface of the slope body 5, and each blind hole 50 extends into the slope body 5;

[0054] B, evenly set a plurality of openings on the anchor rod 2 and place elastic protective sleeves 20 on the side of the anchor rod 2;

[0055] C, install the lower end of the anchor rod 2 into the blind hole 50, and fix it by grouting;

[0056] D, the two ends of the reinforcement ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com