Energy supply system and method for integrated fuel cell and supercritical carbon dioxide solar thermal power generation

A solar thermal power generation, fuel cell technology, applied in the direction of solar thermal power generation, fuel cells, electrochemical generators, etc., can solve the problems of circulating heat supply limitation, the danger of nuclear power plants, the large area of nuclear power plants and concentrating solar fields, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

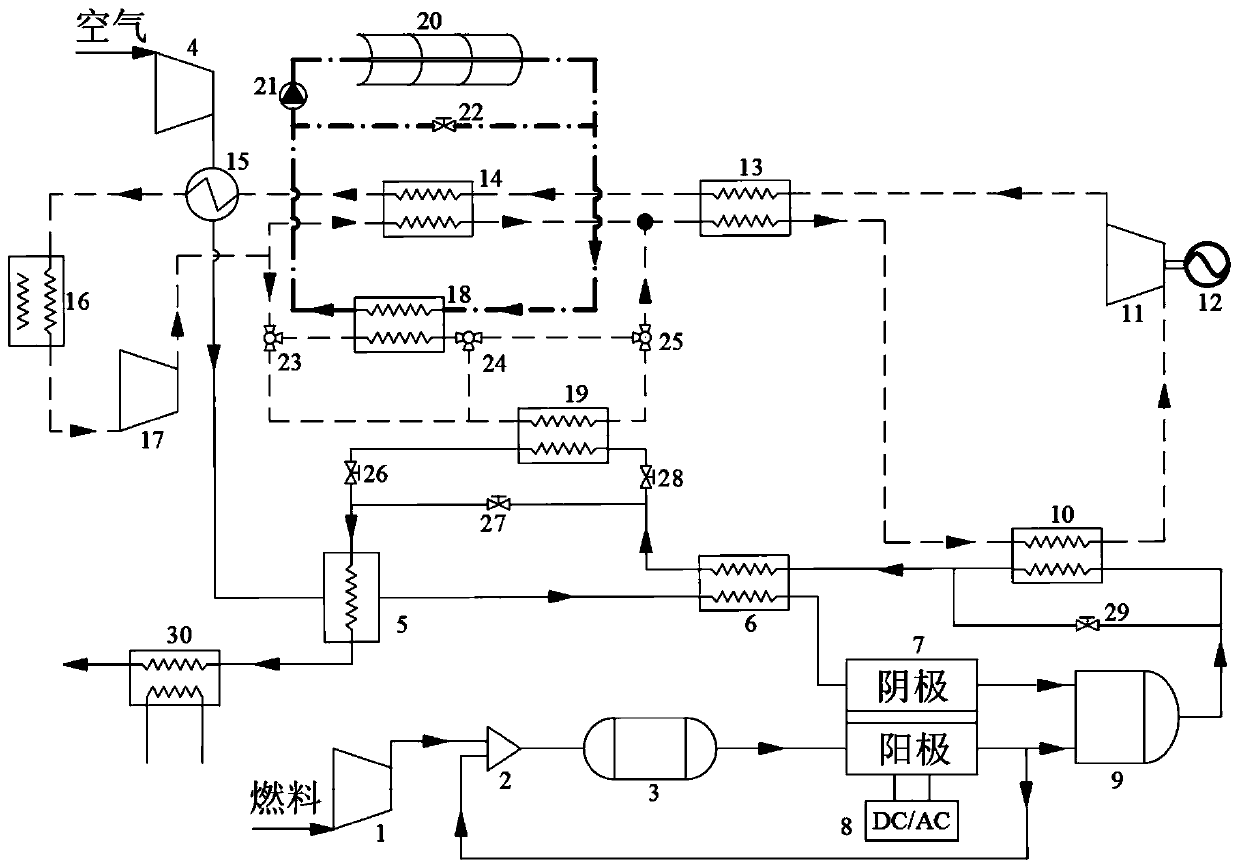

[0033] See figure 1 As shown, the present invention provides an energy supply system integrating fuel cell and supercritical carbon dioxide solar thermal power generation, including a solid oxide fuel cell subsystem, supercritical CO 2 Circulation subsystem and concentrating solar heat collection subsystem.

[0034] The solid oxide fuel cell subsystem includes fuel compressor 1, mixer 2, pre-reformer 3, air compressor 4, air low-temperature regenerator 5, air high-temperature regenerator 6, solid oxide fuel cell 7, inverse Converter 8, combustion chamber 9 and waste heat recovery device 30. The outlet of the fuel compressor 1 is connected to the first inlet of the mixer 2, the outlet of the mixer 2 is connected to the inlet of the pre-reformer 3, and the outlet of the pre-reformer 3 is connected to the anode inlet of the solid oxide fuel cell 7. The anode outlet of the fuel cell 7 is divided into two paths, one is connected to the second inlet of the mixer 2, and the other is con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com