Micro force control system based on interference differential displacement method

A differential displacement and control system technology, applied in control/regulation systems, non-electric variable control, mechanical pressure/force control, etc. The effect of improving accuracy and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

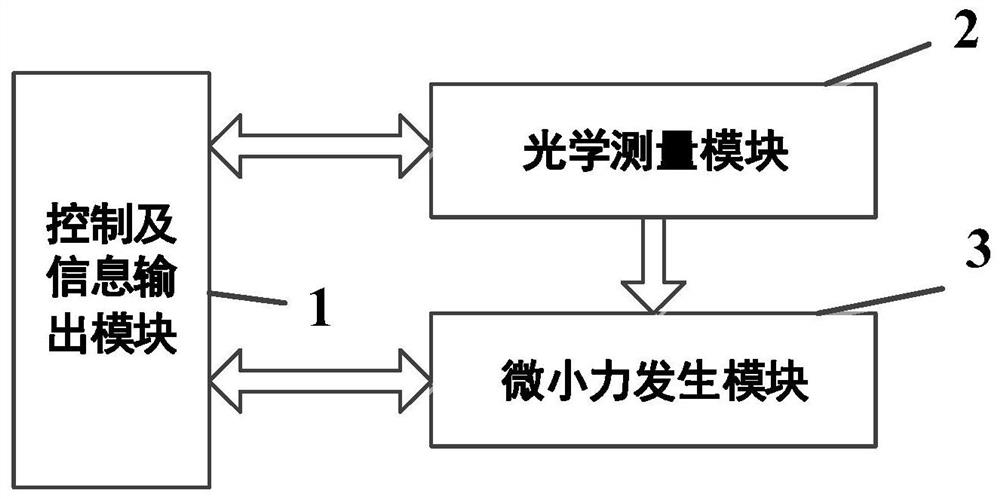

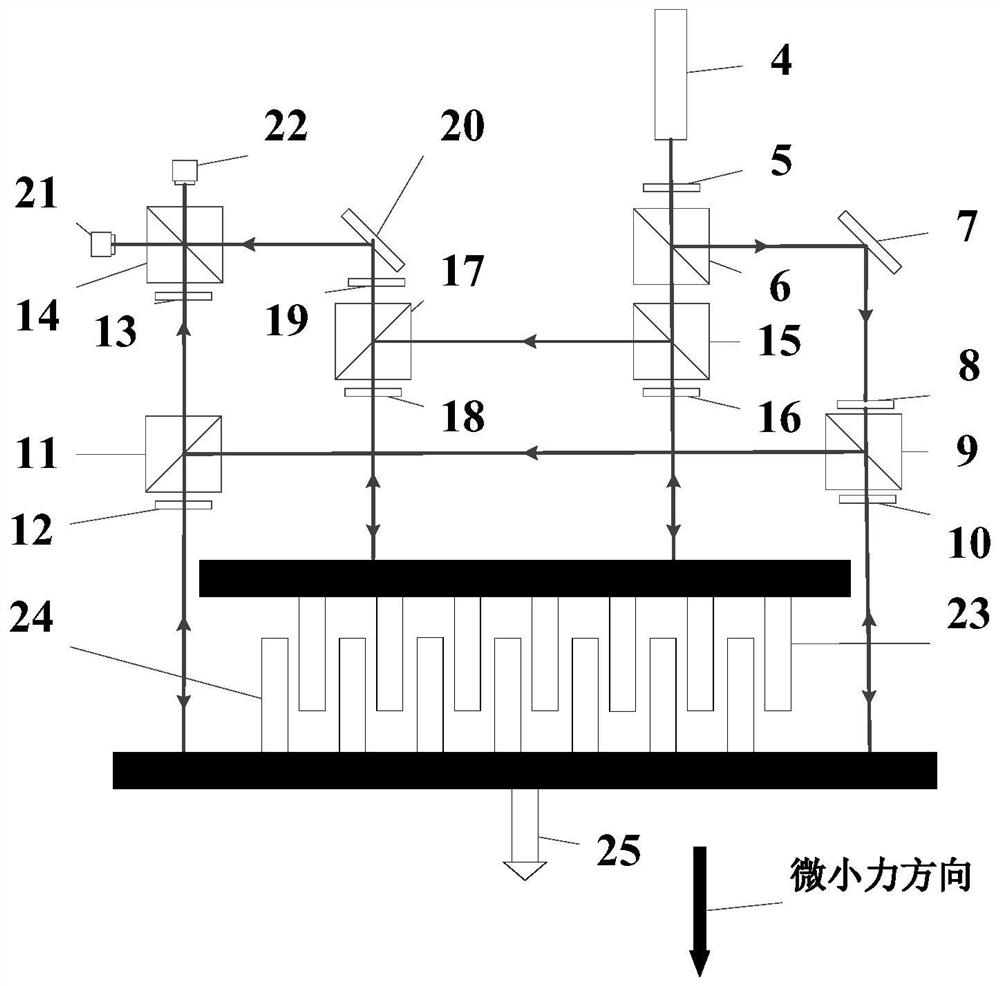

[0020] Such as figure 1 , 2 As shown, the micro-force control system of the interference differential displacement method disclosed in this embodiment is composed of a control and information output module, an optical measurement module 2 and a micro-force generating module 3 . The control and information output module 1 is used for optical measurement signal measurement, micro force generation and calculation, and external communication of control and signals. The measured value and calculated control value of the optical measurement module 2 and the micro force value establish a corresponding relationship, and the comprehensive calculation output Small force data. The micro-force generating module 3 utilizes the electrostatic force method, and adopts a comb structure to improve the resolution and range of the electrostatic force to obtain micro-force values. The system controls the change of electrostatic force and uses the method of elastic deformation of the structure to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com