Semi-transparent photovoltaic tile

A photovoltaic tile, translucent technology, applied in the direction of photovoltaic modules, photovoltaic power generation, photovoltaic module support structures, etc., can solve the problems of high installation and maintenance costs, inflexibility, inconvenient transportation, etc., achieve reinforcement and installation costs, and easy operation And flexible, easy to transport the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

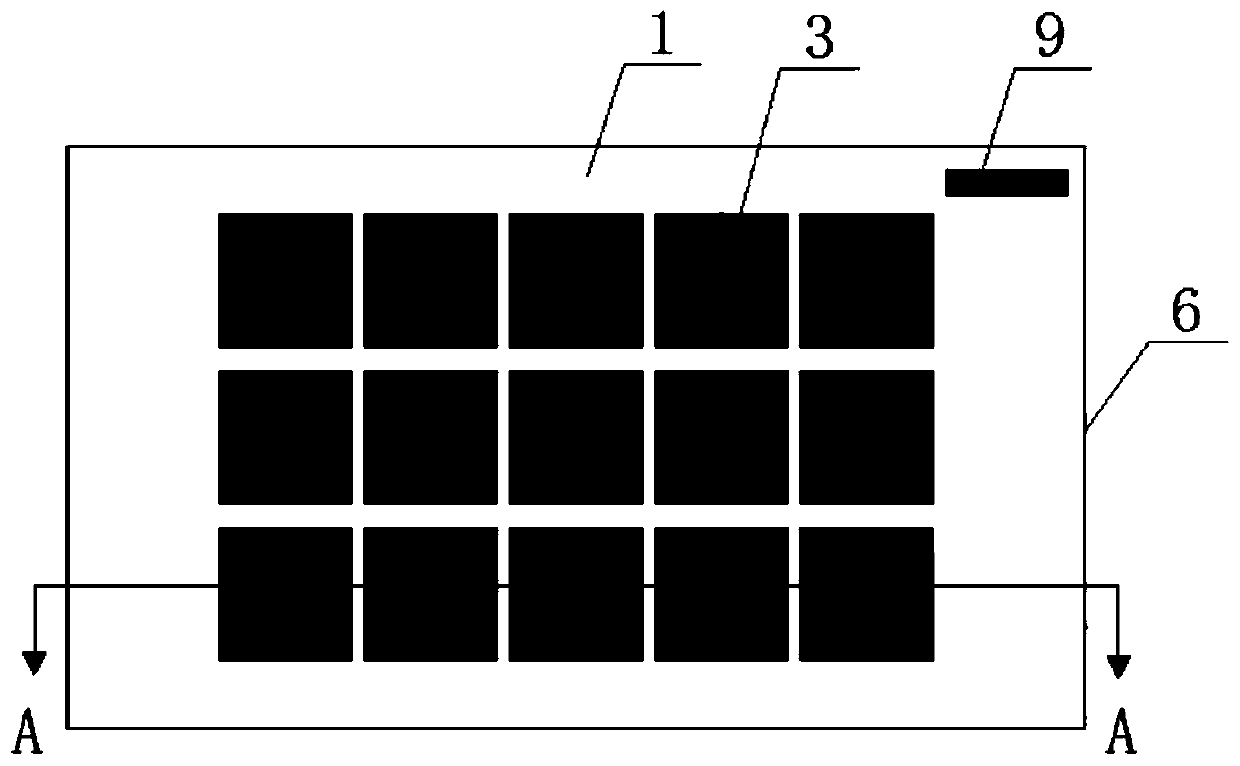

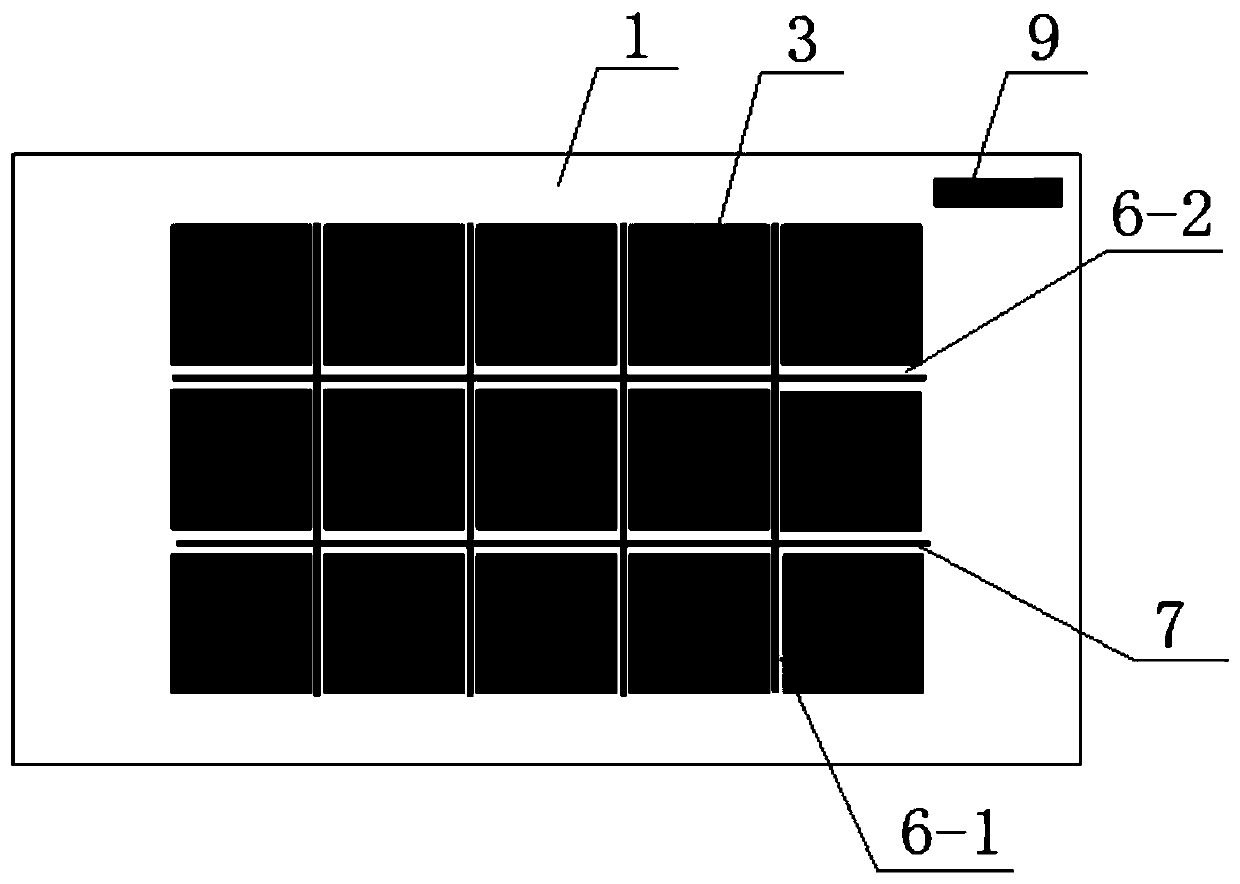

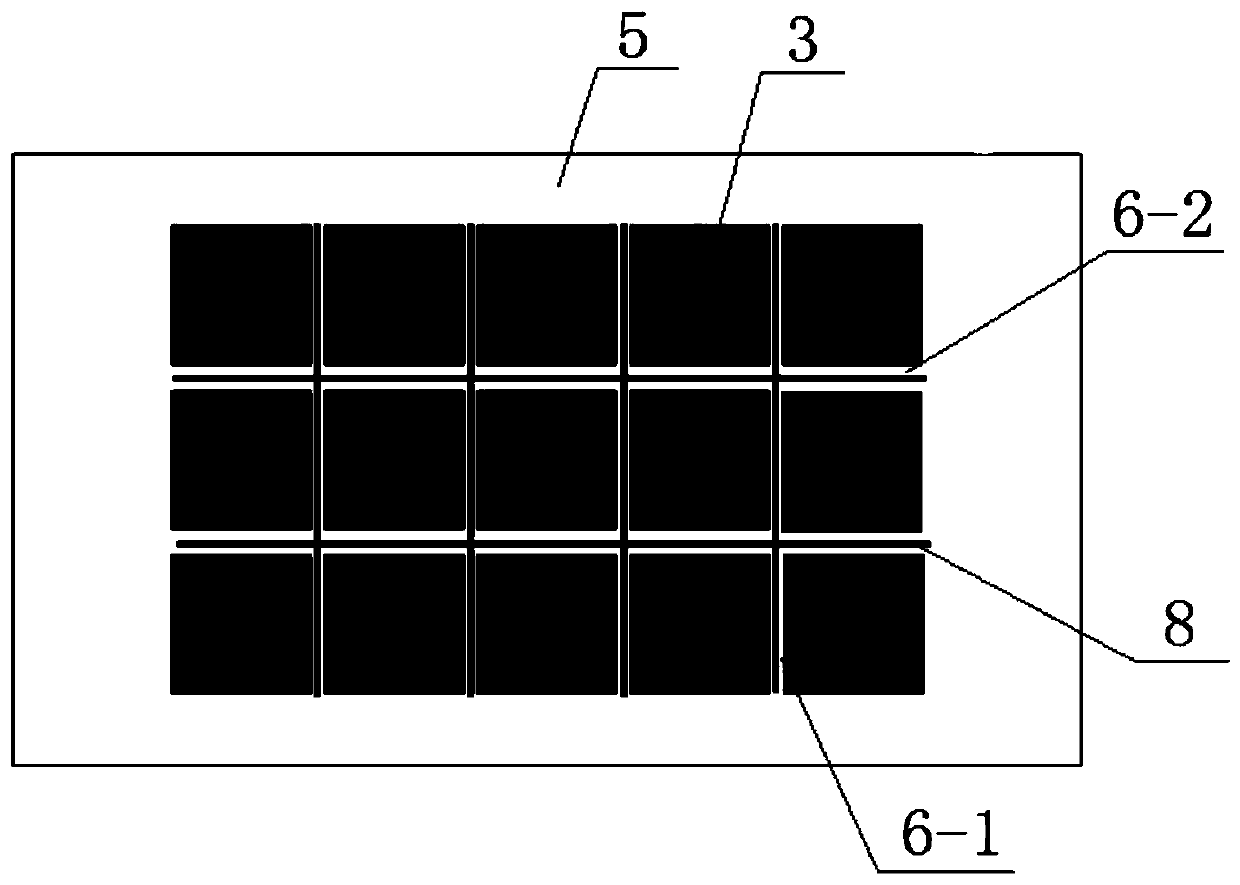

[0040] Specific implementation mode one: as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 with Figure 7 As shown, this embodiment includes a front film layer 1, a first film layer 2, a photovoltaic cell layer, a second film layer 4 and a back film layer 5, the front film layer 1, the first film layer 2, the photovoltaic cell layer The battery layer, the second adhesive film layer 4 and the back film layer 5 are integrally formed, and the front film layer 1 and the back film layer 5 are sheets made of transparent materials.

[0041] Further, the front film layer 1 , the first film layer 2 , the second film layer 4 and the back film layer 5 are all layers made of flexible materials.

[0042] Further, the photovoltaic cell layer includes a plurality of photovoltaic cell sheets 3, the plurality of photovoltaic cell sheets 3 are on the same horizontal plane, each photovoltaic cell sheet 3 is rectangular in shape, and the plurality of photovoltaic cell sh...

specific Embodiment approach 2

[0052] Specific implementation mode two: as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 with Figure 7 As shown, this embodiment includes a front film layer 1, a first film layer 2, a photovoltaic cell layer, a second film layer 4 and a back film layer 5, the front film layer 1, the first film layer 2, the second film layer The second adhesive film layer 4 and the back film layer 5 are arranged horizontally from top to bottom sequentially, the front film layer 1 and the first adhesive film layer 2 are bonded to each other and made into one, and the second adhesive film layer 4 and the back film layer 5 are bonded to each other Made into one body, the front film layer 1 and the back film layer 5 are sheets made of transparent materials, which have a light-transmitting effect. The front film layer 1, the first film layer 2, the second film layer 4 and the back film layer 5 are all flexible sheets, which are easy to cut and fold. The photovoltaic cell...

specific Embodiment approach 3

[0064] Specific embodiment three: This embodiment is a further limitation of specific embodiment one or two. The photovoltaic cell sheet 3 is a transparent photovoltaic cell sheet, and the photovoltaic cell layer formed by a plurality of transparent photovoltaic cell sheets is a transparent photovoltaic cell layer. 1. The first adhesive film layer 2, the second adhesive film layer 4 and the back film layer 5 form an overall transparent structure, which is suitable for agricultural greenhouses or other occasions requiring light transmission, and can also be applied to other places with visual requirements. The photovoltaic battery sheet 3 is an existing photovoltaic battery sheet with light transmission performance.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com