Battery high-voltage copper bar mounting device

A mounting device and high-voltage technology, which is applied in the assembly/disassembly of contact parts and the manufacture of contact parts, etc., can solve the problems of loss, workpiece deviation from the original position, and low positioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

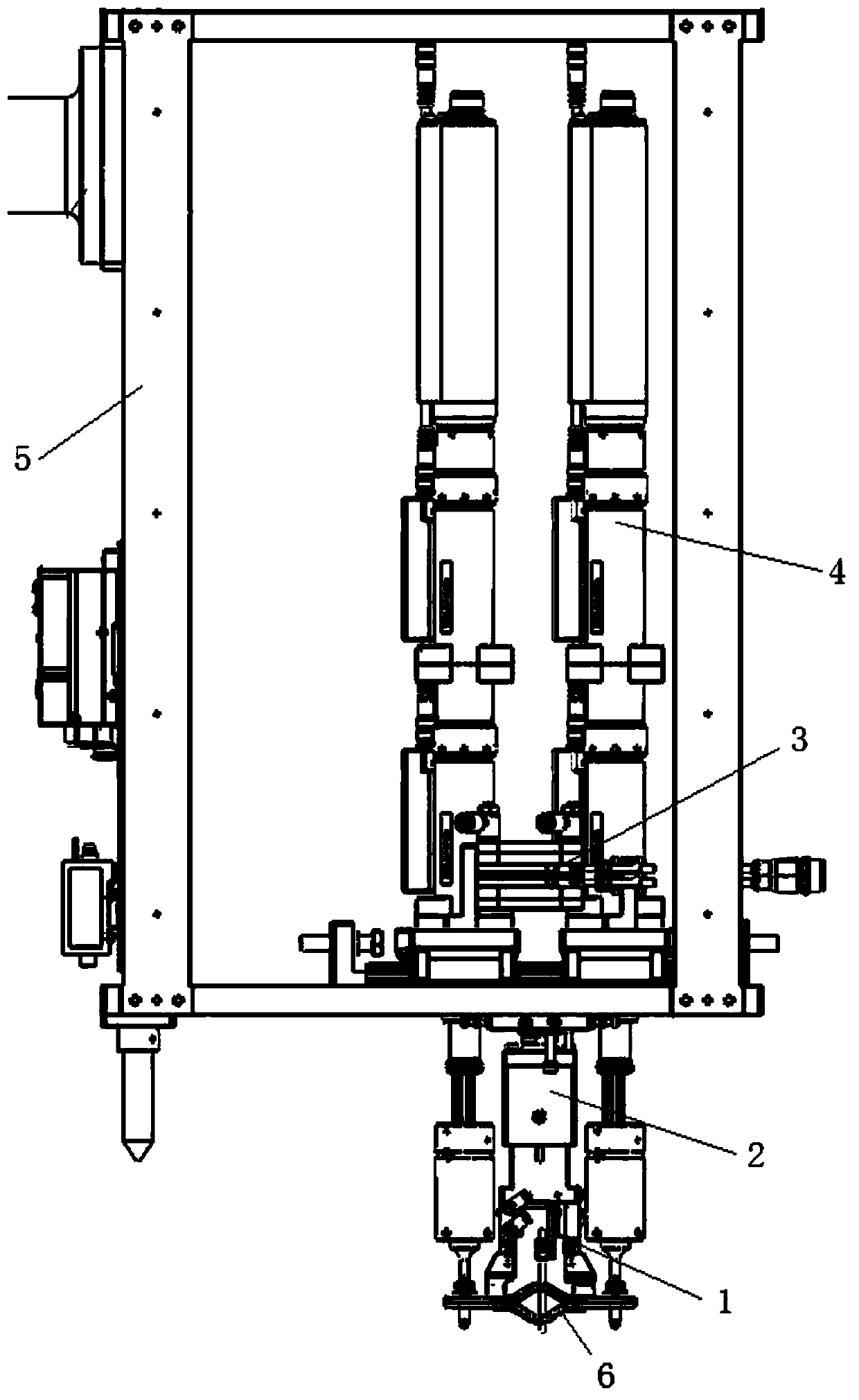

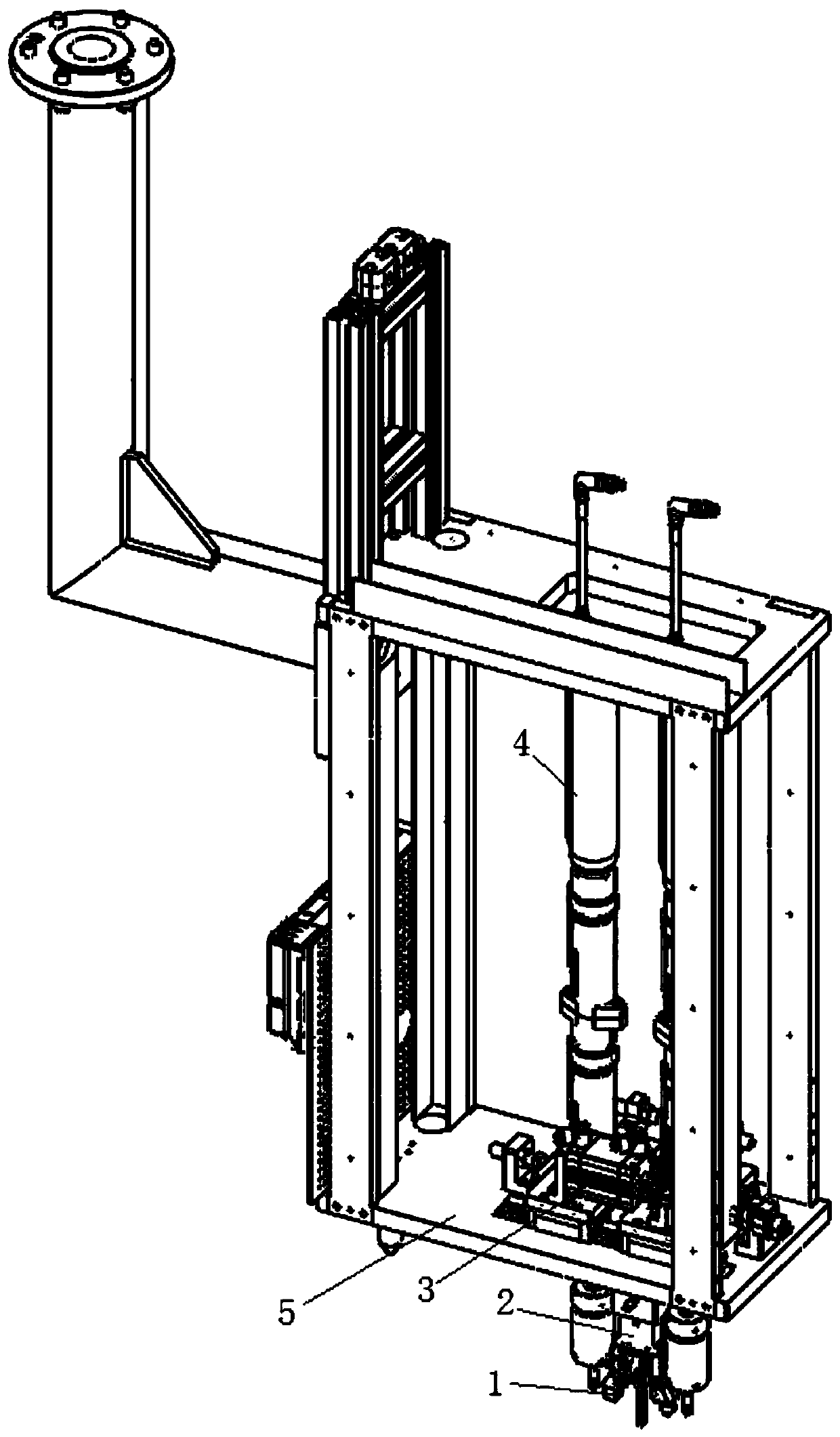

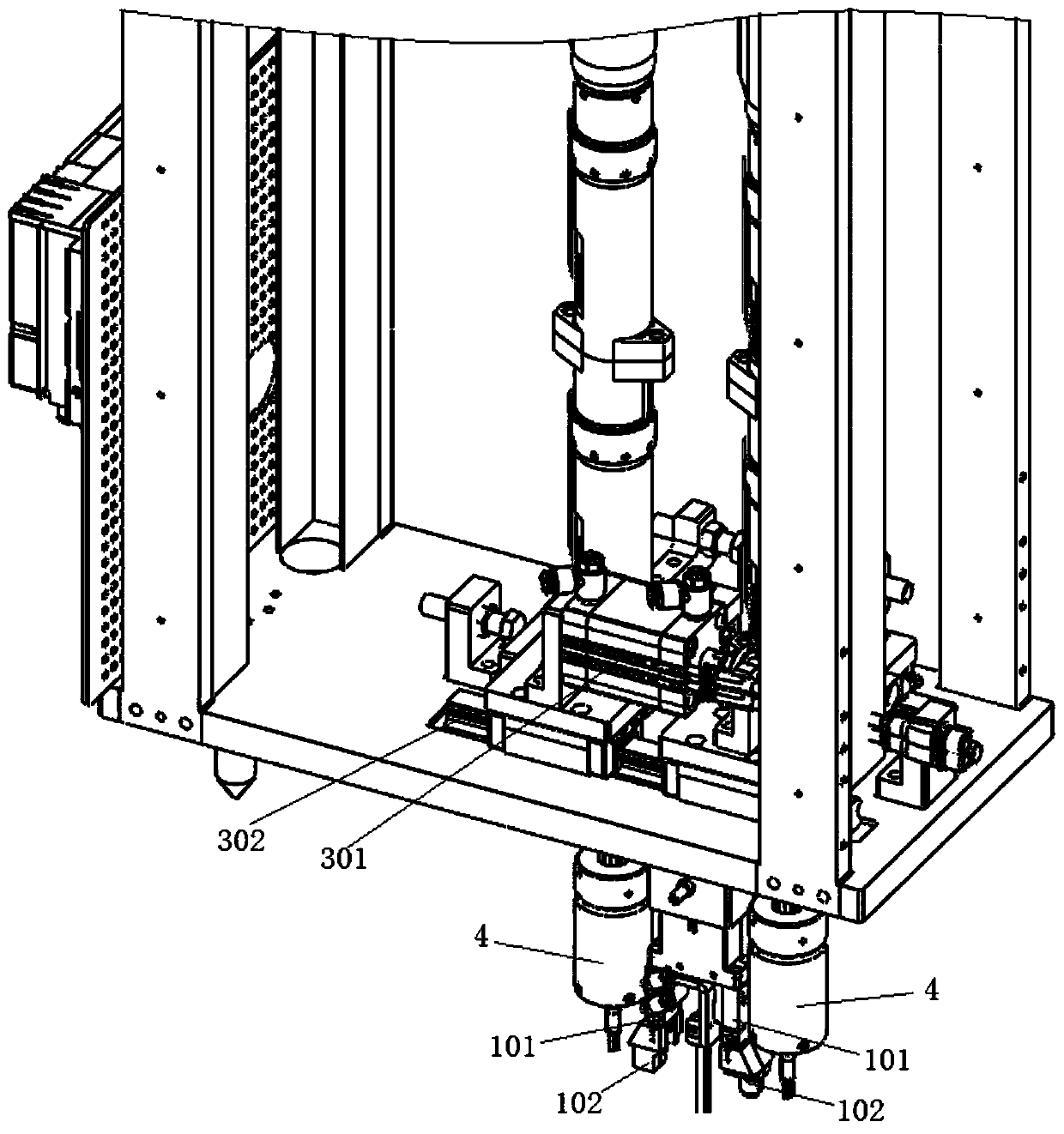

[0030] see figure 1 , figure 2 , image 3 , Figure 4 , a battery high-voltage copper bar installation device provided in an embodiment of the present invention, such as figure 1 , figure 2 , image 3 , Figure 4 As shown, the device includes a grabbing mechanism 1, a floating mechanism 2, a displacement mechanism 3, and a tightening gun module 4, and the displacement mechanism 3 and the tightening gun module 4 are installed on the robot flange connector 5; The robot flange connector 5 is made of high-strength aluminum.

[0031] The grabbing mechanism 1 is installed below the floating mechanism 2, and the grabbing mechanism 1 is used to grab the high-voltage copper bar of the battery; the grabbing mechanism 1 includes a jaw cylinder 101 and a jaw 102; the gripper The air cylinder 101 is used to drive the jaws 102 to grab the high-voltage copper bar 6 of the battery. There are two jaw cylinders and two jaws respectively, and the two jaw cylinders 101 are connected to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com