Counter for workpieces produced in machining way

A technology for producing workpieces and counters, which is applied in metal processing equipment, manufacturing tools, accessories of toolholders, etc., can solve the problems of high labor intensity of operators, difficulty in workshop management, and inaccurate quantities, so as to improve the effective working time and count. Accurate, Work-Reduced Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

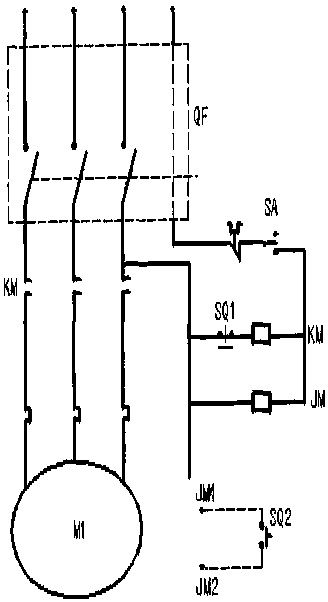

[0009] Accompanying drawing is a kind of specific embodiment of the present invention. The simple lathe counting device is characterized in that it includes a travel switch installed behind the guide rail of the instrument trolley, the first pair of contacts SQ 1 of the travel switch is connected in series with the AC contactor KM, the transfer switch SA, the power circuit breaker QF and the motor M1 Then, the AC contactor KM is connected with the motor M1, and the second pair of contacts SQ2 of the travel switch is connected with the counter JM.

[0010] The simple lathe counting device, when working, close the power circuit breaker QF, adjust the transfer switch SA to the working position, when the machine tool operator operates the handle, the first pair of contacts SQ1 of the travel switch is closed, and the AC contactor KM is closed. The motor M1 runs according to the designated direction, and starts to process the workpiece; when the workpiece is processed and the carria...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com