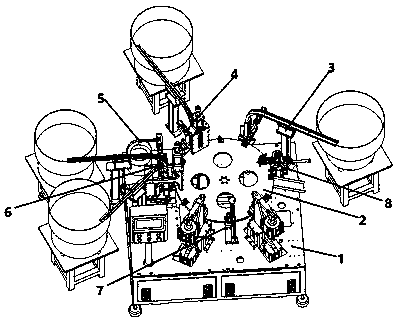

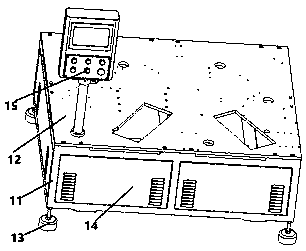

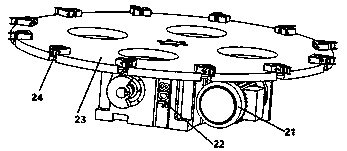

Full automatic assembling equipment for two-stage force hinge

An assembly equipment and fully automatic technology, applied in the field of hinge assembly, can solve problems such as lack of stable and effective control of quality, large cost investment, assembly errors, etc., to reduce manual labor, reduce labor costs, and improve yield rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0014] Embodiment 2, the difference between this embodiment and Embodiment 1 is that the Lizai riveting mechanism is set between the Lizai feeding device and the four-hole spring feeding device, and the Lizai feeding device is immediately fixed after the nail is penetrated. Riveting is carried out to avoid affecting one of the rivets when the other is riveted.

[0015] Compared with the prior art, the beneficial effect is that the design of the present invention is reasonable by adopting the above scheme. By splitting the production process of the two-stage force hinge and designing corresponding mechanical working groups corresponding to each stage, the present invention is easy to maintain and utilizes Automated technology for production reduces a lot of manual labor, reduces labor costs, improves labor efficiency, realizes stable and precise assembly production, further improves the yield rate of production, and is suitable for mass production.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com